Understanding Safety Light Drapes: Exactly How They Function and Why They Issue in Modern Manufacturing

In today’s busy production setting, worker safety and security is no more just a regulative requirement– it’s an essential consider operational efficiency, employee retention, and overall company success. According to the International Labour Organization (ILO), over 340 million work-related mishaps happen each year worldwide, with a substantial portion occurring in industrial settings including machinery. One of one of the most efficient and extensively taken on remedies for preventing these mishaps is the security light curtain, a non-contact guarding gadget that has transformed equipment safety and security because its introduction decades earlier.

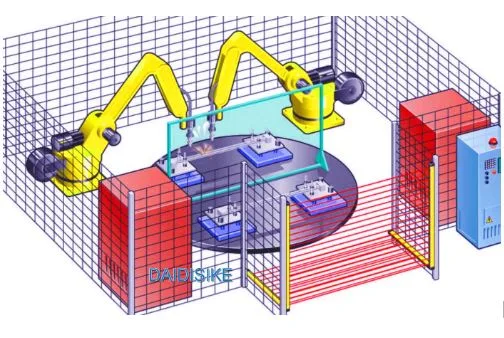

Safety light drapes, additionally referred to as light guards or optical guards, develop an undetectable safety obstacle utilizing infrared beams. When any type of object– normally a person’s hand or body– interrupts these beams, the system immediately indicates the device to quit, avoiding potential injury. These gadgets are especially useful in high-risk locations like press brakes, robotic welding cells, product packaging lines, and automated assembly terminals. Unlike physical obstacles or mechanical guards, light drapes allow unlimited access for product handling while preserving high degrees of protection.

This write-up discovers the basics of safety and security light drapes, delving right into their operating principles, essential technological specifications, choice considerations, real-world applications, and why they remain indispensable in contemporary Industry 4.0 centers.

What Are Safety And Security Light Curtains?

At their core, security light curtains contain two primary components: a transmitter unit that releases numerous parallel infrared light beams and a receiver system that finds those beam of lights. These systems are installed opposite each other, developing a detection area (often called the “drape”) that covers the unsafe area.

Safety light curtains are categorized into different types based on global standards. One of the most typical difference is in between Kind 2 and Kind 4 gadgets, as specified by IEC 61496-1 and -2:

– ** Kind 2 light drapes ** are ideal for lower-risk applications. They have less complex fault detection and can enable a single beam disruption prior to setting off a quit signal.

– ** Kind 4 light curtains ** offer the greatest degree of safety and security, with advanced self-monitoring capacities. They detect mistakes in the system itself (like a stopped working emitter or receiver) and require numerous repetitive checks to guarantee dependability.

Many contemporary production centers choose Type 4 drapes due to the fact that they achieve Efficiency Degree e (PL e) under ISO 13849-1 and Security Honesty Level 3 (SIL 3) under IEC 61508– certifications that assure outstanding dependability in preventing accidents.

These tools integrate effortlessly with machine control systems by means of safety and security relays or controllers. When the curtain is clear, the outputs (usually OSSD– Result Signal Changing Device– signals) stay energetic, permitting the machine to operate. Any kind of interruption changes the outcomes off, stopping dangerous activity.

Exactly How Security Light Curtains Work: The Technical Concept

The procedure of security light drapes counts on the time-of-flight or beam interruption concept making use of infrared light. The transmitter releases pulsed infrared beams at specific periods, and the receiver synchronizes to identify just those specific pulses, straining ambient light interference.

Below’s a step-by-step break down:

- ** Beam Emission **: The transmitter has an array of infrared LEDs that sequentially send out beam of lights throughout the secured location. Resolution– the minimal things size that can be identified– ranges from 14mm (finger discovery) to 40mm or even more (hand or body discovery).

- ** Beam Discovery **: The receiver has matching photodiodes or phototransistors that check inbound light beams. Advanced systems utilize multiplexing to avoid cross-talk between adjacent beam of lights.

- ** Synchronization and Tracking **: The units interact via wired synchronization or optical sync light beams. Inner microprocessors continually look for appropriate alignment, beam toughness, and system health and wellness.

- ** Interruption Response **: When several light beams are blocked, the receiver right away shuts down the OSSD outputs. Feedback time– the delay from disruption to stop signal– is generally under 20 nanoseconds, quickly enough to stop even high-speed machinery prior to call.

- ** Silencing and Blanking **: For practical use, functions like muting (momentarily bypassing the curtain for material passage) and blanking (disregarding taken care of objects like conveyor sustains) are configurable via software or DIP buttons.

For those seeking a much more detailed, step-by-step description of how do security light curtains work, consisting of wiring representations and real setup examples, I recommend this comprehensive overview that covers whatever from basic wiring to innovative diagnostics.

Modern light curtains likewise include functions like plunging (attaching numerous sets for bigger locations), incorporated condition signs, and compatibility with IO-Link for wise manufacturing facility combination.

Secret Technical Parameters and Option Considerations

Choosing the appropriate safety and security light curtain calls for examining several parameters:

– ** Resolution **: Figures out discovery ability. 14-20mm for finger defense; 30-40mm for hand/arm; bigger for body discovery.

– ** Protected Height **: The vertical protection location, generally from 150mm to 1800mm or even more.

– ** Array **: Discovery distance in between transmitter and receiver, frequently 0.2-20 meters depending upon design.

– ** Feedback Time **: Crucial for computing risk-free installing distance (per ISO 13855 formula: S = (K × T) + C, where K is technique speed, T is overall quit time, and C is intrusion range).

– ** Environmental Ranking **: IP65/IP67 for dust and water resistance in rough manufacturing facilities.

– ** Certifications **: Must abide by regional criteria– CE noting in Europe, UL in North America, and so on.

Various other functions to consider include vibration resistance, electromagnetic immunity (EMC), and assimilation with safety PLCs. Budget-conscious buyers ought to note that while premium brand names dominate, dependable alternatives from specialized suppliers supply equivalent efficiency at reduced expenses.

Real-World Applications and Advantages

Security light curtains are deployed throughout sectors:

– ** Metalworking **: Protecting operators on hydraulic presses and punch machines.

– ** Automotive **: Securing robot assembly lines and welding terminals.

– ** Packaging and Logistics **: Monitoring conveyor entry factors and palletizers.

– ** Electronic devices **: Making certain safety around pick-and-place robots.

A significant study from a European vehicle vendor showed a 70% decrease in near-miss occurrences after setting up Type 4 light curtains on stamping lines. The financial investment spent for itself within 18 months via reduced downtime and insurance coverage costs.

Past mishap avoidance, light curtains improve efficiency by removing physical guards that slow product flow. They additionally support ergonomic designs, enabling drivers to function closer to makers without compromising security.

For manufacturers seeking to execute or update their safety systems, comprehending the safety light curtain sensors working concept extensive is important for correct setup and maintenance.