Unlocking the Power of Foam Conversion: Innovative Solutions

Introduction

Foam is one of the most versatile materials in modern manufacturing, offering everything from cushioning and insulation to acoustic solutions and protective packaging. But raw foam alone isn’t always enough to meet industry demands. That’s where foam conversion comes into play—a process that transforms basic foam into highly functional products for a variety of sectors.

Whether you’re in construction, automotive, healthcare, or packaging, understanding foam conversion and how it can elevate your products is essential. In this article, we’ll explore the processes, applications, benefits, and innovations behind foam conversion, including insights from Acoustafoam’s industry-leading expertise.

What is Foam Conversion?

At its core, foam conversion is the process of transforming foam into tailored products to meet specific functional, design, or technical requirements. This transformation can range from simple cutting and slitting to advanced CNC profiling for bespoke acoustic solutions.

The goal of foam conversion is to turn standard foam materials into functional solutions for real-world applications. Different types of foam—such as polyurethane, polystyrene, and polyethylene—offer unique properties that suit various industries.

Foam conversion is not just about shaping foam; it’s about engineering solutions. Whether creating seating cushions, soundproofing panels, or thermal insulation, foam converter bring expertise, precision, and innovation to the process.

Key Foam Conversion Processes

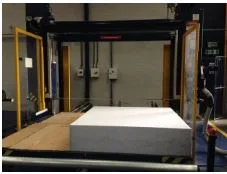

Foam conversion can involve multiple processes depending on the desired end product. Leading foam converters like Acoustafoam utilize advanced machinery and techniques to achieve high-quality results:

- Cutting

Foam can be cut into precise shapes and sizes using band saws, hot wire cutters, water jets, or die-cut presses. This ensures consistent dimensions for any application. - Profiling and CNC Machining

CNC profiling machines allow for complex, bespoke shapes, especially for acoustic and automotive applications. From custom engine room insulation to cabin headliners, CNC profiling guarantees precision. - Laminating

Foam layers can be bonded together or with other materials for added durability, insulation, or soundproofing. Laminating expands foam’s functional potential, creating multi-layered products that meet technical requirements. - Moulding

Injection or compression moulding enables foam to take on complex forms for seating, medical cushions, or automotive components. - Fabrication

Finished foam products can be assembled with other materials, such as fabrics or foils, to create complete solutions for industrial or consumer applications.

Types of Foam Commonly Used in Conversion

Understanding foam types is essential for choosing the right material for your application:

- Polyurethane Foam: Widely used in mattresses, cushions, insulation, and packaging. Flexible and versatile, it adapts well to diverse applications.

- Polystyrene Foam: Lightweight and insulating, it’s perfect for packaging, disposable containers, and construction insulation.

- Polyethylene Foam: Durable and moisture-resistant, often used in protective packaging, industrial insulation, and padding.

Each type of foam has distinct characteristics, and selecting the right one is crucial for achieving the desired functionality.

Applications of Foam Conversion

Foam conversion is far-reaching, impacting multiple industries in unique ways:

- Acoustic Solutions

Acoustic foam panels are crafted to reduce echoes and improve sound clarity. By using CNC profiling and precise cutting, foam can be shaped into wedges, pyramids, or egg crates, which maximize sound absorption. Common applications include recording studios, home theaters, offices, and public spaces. - Automotive Components

Foam is converted into headrests, armrests, cabin insulation, and engine room padding. High-density, Class 0 foam ensures excellent sound absorption while being fire-resistant and durable. - Construction and Insulation

Foam conversion supports thermal and sound insulation in construction projects. Class 0 profile foam, for example, provides fire-resistant, flexible, and chemically inert solutions for challenging applications like generator canopies and marine engine rooms. - Packaging

Foam conversion allows custom-fit packaging solutions to protect delicate goods during shipping. Die-cut and laminated foam inserts ensure maximum protection with minimal material waste. - Medical and Healthcare

Foam is converted into orthopaedic supports, medical cushions, and ergonomic products, offering comfort and functionality for patients and practitioners.

Benefits of Foam Conversion

The versatility of foam conversion offers numerous advantages:

- Customization: Foam can be converted to precise specifications, meeting both size and functional requirements.

- Enhanced Functionality: Laminating or profiling foam enhances its acoustic, thermal, or protective properties.

- Safety and Compliance: Class 0 and fire-resistant foams meet strict safety standards for high-risk environments.

- Sustainability: Some foam conversion processes incorporate recycled materials, reducing environmental impact.

- Industry Expertise: Experienced foam converters can solve complex challenges, from soundproofing around radiators to thermal insulation on yachts.

By leveraging these benefits, companies can deliver products that meet technical specifications while providing comfort, safety, and durability.

Environmental Considerations in Foam Conversion

Modern foam conversion increasingly emphasizes sustainability. Many converters use eco-friendly materials, recycled foams, and efficient production processes to reduce waste. By integrating these practices, foam conversion not only meets functional needs but also supports environmental responsibility.

Quality Control and Industry Expertise

A critical aspect of foam conversion is ensuring consistent quality. Leading companies implement rigorous quality checks to guarantee that every product meets industry standards and customer expectations. Expertise in handling different foam types allows converters to advise clients, optimize solutions, and deliver products that perform reliably across sectors.

Conclusion: Why Foam Conversion Matters

Foam conversion is more than a manufacturing process—it’s a bridge between raw materials and practical solutions. From acoustic panels to automotive components and protective packaging, foam conversion empowers industries to innovate and solve complex problems.

By choosing a skilled foam converter, businesses can access customized solutions, advanced technologies, and sustainable practices, ensuring that foam products meet both functional and regulatory requirements. Whether it’s enhancing sound quality, protecting valuable goods, or providing thermal insulation, foam conversion remains an essential part of modern manufacturing.

For inquiries on foam conversion products, contact experts like Acoustafoam to explore tailored solutions for all types of applications.