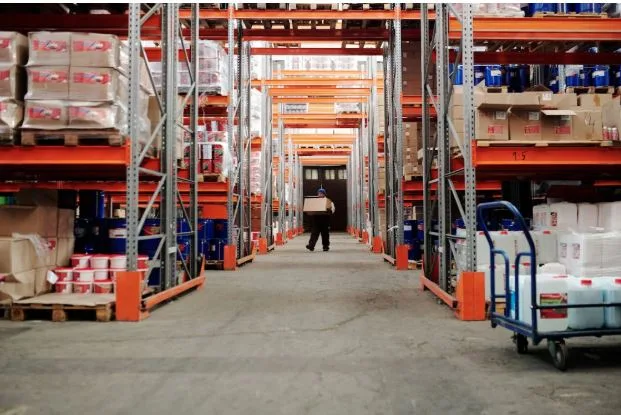

Warehouse Optimization: How Businesses Can Maximize Storage Without Expanding Facilities

Running out of warehouse space does not always mean you need a bigger building. In many operations, the real issue is wasted vertical space, poor layout decisions, or outdated storage equipment.

Smart warehouse optimization helps you unlock capacity you already have, without the cost and disruption of expanding. A strategic approach can reveal surprising opportunities inside your existing four walls.

Reconfigure the Layout

A cluttered layout quietly limits your storage potential. Narrow aisles in the wrong places, inconsistent slotting, and poorly defined pick paths often reduce usable capacity.

Start by reviewing product movement data and grouping high-turn items near packing and shipping zones. Fast-moving inventory should be easy to access, not buried behind slow-moving pallets.

Clear travel lanes and logical zoning reduce congestion and open up overlooked storage areas.

Also, reworking aisle widths and repositioning racks can increase storage density without changing your building footprint.

Invest in Pallet Racking Systems

Floor-stacking may seem simple. But it wastes vertical space and increases product damage.

Businesses that handle palletized inventory can significantly improve storage density by installing pallet racking systems that match their load and workflow requirements.

Selective racks work well for operations that need direct access to every pallet. Drive-in or push-back systems increase density for high-volume SKUs with consistent turnover.

Matching the configuration to your inventory profile ensures every level of vertical space is used effectively. Upgrading to properly rated and professionally configured racking improves safety, organization, and long-term scalability.

Implement Smart Inventory Management Practices

Excess inventory often consumes more space than inefficient shelving. Slow-moving and obsolete products quietly fill valuable rack positions that should support revenue-generating stock.

Warehouse management systems have become standard tools for improving visibility. According to an industry overview by Transped, most warehouses now rely on digital systems to track inventory and streamline operations.

Better visibility allows you to identify overstock issues earlier. It also enables you to adjust purchasing decisions before space becomes constrained.

Several process improvements can quickly free up capacity:

- Review slow-moving SKUs on a set schedule

- Adjust safety stock levels based on real demand patterns

- Remove obsolete inventory before peak season

Leaner inventory reduces congestion and improves picking speed. It also makes cycle counts easier and more accurate.

Add Mezzanines and Vertical Storage Solutions

The air above your warehouse floor is often the most underutilized asset in the building. High-clearance facilities can support mezzanines, multi-tier shelving, or elevated work platforms without expanding outward.

Installing a structural mezzanine creates a second level for light storage, kitting, or assembly. Ground-level space can then be reserved for bulk pallets or fast-moving goods. Separating functions vertically also improves traffic flow and safety.

Modern logistics demand continues to put pressure on industrial space availability. Research highlighted by Cushman & Wakefield shows ongoing demand for well-located warehouse facilities.

Building a Smarter Path Forward With Warehouse Optimization

Warehouse optimization works best when approached as a system, not a quick fix. Layout improvements, upgraded pallet racking systems, tighter inventory controls, and vertical build-outs each play a role in maximizing capacity.

Growth does not always require a new address. If you are evaluating storage upgrades or redesigning your facility, explore solutions that fit your operation and support long-term efficiency. And keep an eye on more informative articles like this one!