Welding Positioner: Enhance Your Weld with Precision and Productivity

Understanding the Weld Positioner

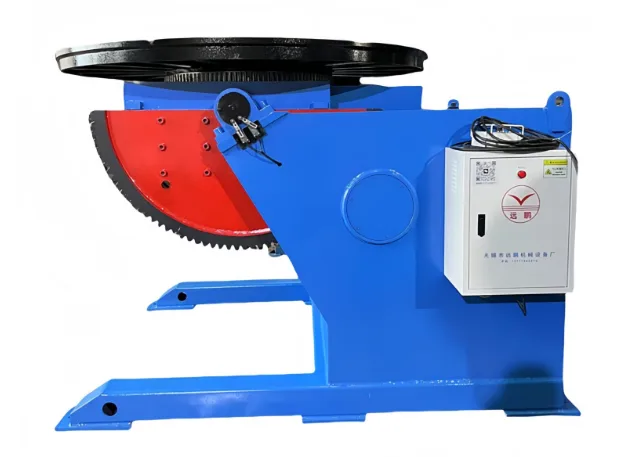

A welding positioner is a piece of equipment that takes hold of a workpiece and manipulates it. This gives a welder the opportunity to refine and improve the piece’s finish and work it more efficiently. It saves time and ensures the workpiece is in the most optimal position, and less manual repositioning is required. This saves the user time and ensures that the weld is consistent and high-quality. Positioners are of great use in metal fabrication, construction, and manufacturing. These industries are accustomed to the need for high precision and productivity.

If you are looking for more information about the Top Welding Positioner Manufacturers and Supplier in China – RESIZE, go here right away

Types of Weld Positioners

Fixed Welding Positioners

These positioners are the most basic type of welding positioner. They are stationary and hold the workpiece in a fixed position, but are capable of rotating and tilting it.

View Welding Positioner for sale – RESIZE for More Details

Rotary Welding Positioners

These positioners are able to provide 360 degrees of rotation, and are used the most with circular or cylindrical workpieces, for example, tanks and pipes.

Tilt-and-Rotate Weld Positioners

With these positioners, one is provided the most flexibility and to use with complex welds that need to be altered in several different.

Headstock and Tailstock Positioners

These positioners are best for larger and heavier workpieces. They provide end-to-end support and ensure that the workpiece is stable and secure during the welding process.

Benefits of Using a Weld Positioner

Improved Welding Accuracy

More precise and consistent welding is made possible by the correct positioning of all workpieces.

Enhanced Productivity

The time required to complete welding tasks is drastically reduced because there is less manual work to fill out.

Better Operator Safety

A safer working environment is established by weld positioners because they eliminate awkward postures and excessive physical exertion.

Versatility

Due to the numerous types and configurations obtainable, weld positioners can handle an extensive assortment of workpieces and welding methods.

Cost Efficiency

Improved speed and decreased errors result in lower production costs and less wasted materials.

Anyone looking to improve the speed and accuracy of their welding, as well as productivity, will benefit from the use of a welding positioner. Proper application of the various types of positioners available greatly impacts their productivity.

Key Components of a Weld Positioner

The Role of the Chuck

A chuck is one of the most important parts of a weld positioner. It holds the workpiece securely. Because the workpiece is held securely in a chuck, it can be rotated without losing position, and it can be held firmly for continuous welding. Chucks can be made in different sizes and shapes, for example, 3-jaw or 4-jaw chucks, for different workpieces. For different welding applications, a chuck can be designed for different workpieces. The quality and precision of the welding is in large part dependent on the chuck. If the chuck works poorly, the weld workpiece may be poorly aligned or misaligned, causing it to be of low quality.

Equipment Needed for Rotary Welding

In rotary welding, there are several specific pieces of equipment that are needed to achieve the desired results. One needed tool is the welding positioner, which has the capability to control the rotation of the workpiece. Also needed is the welding torch or other equipment that performs the welding. Other tools that may be used are foot pedals that allow control of the welding speed, and custom attachments that work to hold irregularly shaped pieces of work. The tools are designed to work together in order to perform complicated welding tasks with a good degree of efficiency.

Manual vs. Power Positioners

Selecting either a manual or a power positioner is determined by the needs of your individual welding assignment. Manual positioners tend to be less expensive and are adequate for less elaborate or smaller tasks since the operator adjusts the position themself. In contrast, power positioners afford the operator motorized control of the workpiece, which is essential in handling larger, heavier, and more complex workpieces. Power positioners are suited for work environments where the volume of work is consistently high or where the workpiece needs to be rotated in a consistent manner to produce quality welds. Each option has its pros and cons, and knowing those will help you choose the best positioner.

Applications of Welding Positioners in Industry

Rotary Positioners in Heavy Manufacturing

The importance of rotary positioners in heavy manufacturing industries cannot be overstated. These positioners manage large, heavy workpieces, including those used in construction equipment, oil rig components, and shipbuilding. They enable operators to seamlessly pivot and incline large pieces, which, in turn, diminishes the amount of rotary positioners, reduces manual labor, and eliminates extreme ergonomically driven positions. Positioners achieve a defect-free workpiece which makes them vital for the welding, machining, and assembly operations of heavy manufacturing.

Use of Positioners in Assembly Lines

Welding positioners form part of the automation systems of assembly lines, especially in industries characterized by heavy production. They enable the automation of the sequence and control of the work pieces movement which streamlines workflow and reduces the time needed for production. The automation systems lock the parts in position and control the orientation in relation to the welding gun, which greatly reduces errors. The position systems are especially useful in the automobile and airplane manufacturing industries. The incorporation of position systems onto assembly lines reduces the time andthe ergonomically driven positions expected of the employees.

Welding Positioners for DIY Projects

Welding positioners aren’t strictly for industrial applications; DIY hobbyists and small-scale fabricators have a wider range of positioners to choose from. Hobbyists who want to enhance their welding projects have access to smaller and cheaper positioners. Whether designing custom metal furniture or fixing auto parts, positioners provide control and precision to even novice welders. Reduced strain and concentration on one welding task allows DIY welders to obtain professional results. At home, high-quality positioners simplify intricate, time-consuming projects.

Choosing the Right Welding Positioner

Considerations When Choosing a Product

Numerous considerations must be taken into account when selecting a welding positioner to help satisfy your specific requirements. First, the positioner’s load capacity must be evaluated to determine whether it can support the weight of the workpieces. Rotational speed, as well as the tilt range, should be evaluated, as they most influence the flexibility and optimization of your welding assignments. Furthermore, a positioner with easily operable features is recommended, particularly for novices, to avoid complexity during the initial use. Finally, the selection of robust and durable materials sets the foundation for safety and long-term performance.

Best Accessories for Improved Efficiency

The productivity of a welding positioner can be greatly enhanced with the addition of various tools. Chucks and clamps help keep different workpieces secure while foot pedal control allows for smoother and more accurate operations. Some positioners can be equipped with extra table plates or locating pins for versatility to meet different uses of a project. Furthermore, the efficiency of the welding positioner can be improved with the addition of a rotational speed controller and an angle indicator, which allows the welder to alter the speed and angle to the welder’s preference for more controlled and precise welding. The use of position accessories saves time and ensures quality. Intricate welding work becomes more efficient with these accessories.

Evaluating Rotary and Fixed Positioners

Each of the Rotary and Fixed Positioners caters to different project requirements. Rotary positioners are most useful for applications that involve continuous and variable rotation. Hence, they are suitable for performing circular and tubular welds. They provide the needed versatility and accuracy of movements to facilitate consistent welds. Fixed positioners, however, are better for case applications where the workpiece is welded in a stationary position. These positioners are easier and less expensive to design, which is advantageous for simple welding assignments. In making a selection, the most important factors are the required parameters of the project and the overall complexity of the work to guide the comparison.