What Flow Measurement Equipment Does the Energy Sector Need?

Getting flow right isn’t just a technical detail in energy—it’s money, safety, and compliance all wrapped together. From measuring natural gas in pipelines to tracking steam in refineries and handling multiphase flow coming off a wellhead, the industry depends on accurate, reliable instrumentation. This guide breaks down the core types of flow measurement equipment for energy sector applications, where each shines, and what to consider when selecting, installing, and maintaining your meters.

Why flow measurement matters

Three reasons dominate:

- Custody transfer and revenue: When hydrocarbons change hands, even a 0.1% error compounds into large dollar amounts. Meters used for custody transfer must meet tight accuracy, repeatability, and standards requirements.

- Process control and efficiency: Refineries, LNG trains, and power plants rely on stable flow signals to maintain throughput, heat balance, and yields.

- Safety, emissions, and compliance: Think flare lines, leak detection, and methane reporting. Credible flow data underpins environmental stewardship and regulatory compliance.

Start with the fluid and the job

Before diving into meter types, define the application:

- Phase: Gas, liquid, steam, or multiphase?

- Properties: Pressure, temperature, viscosity, density, compressibility, presence of solids or entrained gas.

- Range: Minimum/maximum flow (turndown), expected Reynolds number, transient behavior.

- Accuracy/standards: Is this custody transfer (API/AGA/ISO), allocation, or process monitoring?

- Site constraints: Straight-run availability, pipe size/schedule, hazardous area classification, ambient conditions.

- Opex & lifecycle: Calibration, proving, maintenance access, and diagnostics.

With the groundwork set, here’s how the main technologies map to energy-sector needs.

Differential pressure (DP) meters: rugged and proven

What they are: Orifice plates, Venturi tubes, flow nozzles paired with DP transmitters and often temperature/pressure compensation.

Where they fit:

- Custody transfer (gas & liquids) when installed and maintained per standards.

- Steam measurement in power and refining utilities.

- High-temperature, high-pressure service where simplicity and metallurgy options matter.

Pros: Established standards and equations, wide applicability, no moving parts (primary element).

Cons: Requires straight runs or flow conditioners; permanent pressure loss; accuracy depends on installation fidelity.

Watchouts: Plate edge wear, impulse line plugging, condensate management for steam, and correct beta ratio selection.

Turbine meters: high accuracy with moving parts

What they are: A rotor spins proportionally to velocity; pickups generate pulses.

Where they fit:

- Liquids (light crude, refined products) and clean gas custody transfer.

- Pipeline proving systems with meter factors.

Pros: Excellent accuracy and repeatability; well-understood proving practices.

Cons: Sensitive to debris, viscosity shifts, and two-phase conditions; moving parts wear.

Watchouts: Filtration, lubricity considerations, and flow conditioners to stabilize profiles.

Positive displacement (PD) meters: direct volumetric workhorses

What they are: Gears, lobes, or pistons that trap and pass discrete volumes.

Where they fit:

- Refined products and crude custody transfer at truck/rail loading racks and LACT units.

- High-viscosity liquids where turbines struggle.

Pros: High accuracy, minimal flow profile sensitivity.

Cons: Moving parts; pressure drop; maintenance intervals.

Watchouts: Temperature compensation, wax/asphaltene management, and compatible seals.

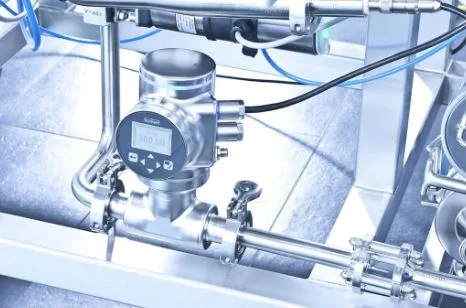

Coriolis meters: direct mass, broad turndown

What they are: Vibrating tubes measure mass flow via Coriolis effect and provide density/temperature.

Where they fit:

- Liquids (crude, condensate, products) custody transfer and allocation.

- Gas at lower pressures/flows, and LPG/LNG loading/unloading (with caution on flashing conditions).

Pros: Direct mass measurement, high accuracy, density and temperature in one instrument, minimal straight-run requirement.

Cons: Cost, pressure drop (for small tubes), and weight on large sizes.

Watchouts: Two-phase flashing, mounting to avoid vibration coupling, and proper zeroing.

Ultrasonic meters: transit-time speed and no obstruction

What they are: Multiple ultrasonic paths measure velocity profile; advanced units compute flow with high accuracy.

Where they fit:

- Natural gas transmission custody transfer (multi-path ultrasonic is the standard bearer).

- Large liquid pipelines, LNG, and water intake utility services.

Pros: Low pressure loss, wide turndown, diagnostics for profile and contamination.

Cons: Requires clean, full pipes; performance depends on acoustic coupling and flow profile.

Watchouts: Correct path configuration, flow conditioning when straight-run is limited, and acoustic noise from control valves.

Vortex meters: steam and utility favorite

What they are: A bluff body sheds vortices proportional to velocity.

Where they fit:

- Steam (saturated and superheated) across power and refining.

- Compressed air and clean liquids in utilities.

Pros: Good for high temperatures, robust, no moving parts.

Cons: Needs stable flow; poorer performance at very low Reynolds numbers.

Watchouts: Piping-induced vibration, straight-run, and using integral pressure/temperature compensation for mass/energy reporting.

Thermal mass meters: direct mass for gas utilities and emissions

What they are: Measure heat dissipation in a gas stream to infer mass flow.

Where they fit:

- Fuel gas to burners.

- Flare lines and vent/methane monitoring (with appropriate designs).

Pros: Direct mass for gas without pressure/temperature compensation; good turndown.

Cons: Sensitive to gas composition changes; not for liquids or wet gas.

Watchouts: Confirm gas mix (Wobbe index shifts), coating effects, and in-situ calibration checks.

Magnetic flow meters: for conductive liquids

What they are: Faraday’s law—only work on conductive fluids.

Where they fit:

- Produced water, cooling water, wastewater, and some chemical utilities.

Pros: No moving parts, negligible pressure loss, accurate on slurries.

Cons: Don’t work on hydrocarbons; require conductivity.

Watchouts: Liner compatibility, grounding, and electrode coating.

Variable area (rotameters) and DP pitot: niche and local indication

Useful for local indication, skids, and low-cost monitoring where exact accuracy isn’t critical. Best avoided for custody transfer.

Special cases in energy

Multiphase and wet-gas measurement

Upstream wells often produce oil, gas, and water simultaneously. Multiphase flow meters (MPFMs) combine differential pressure, gamma densitometry, electrical impedance, or ultrasonic/Coriolis techniques to infer phase fractions and total flow. They’re invaluable for well testing and production allocation where separators are impractical. For wet gas (gas with small liquid loading), specialized wet-gas Venturi or ultrasonic designs with correction models are common.

Flare and environmental reporting

Modern flare meters must handle huge turndown, bidirectional flow, and changing gas composition. Ultrasonic and thermal mass designs built for flare service provide diagnostics for compliance and ESG reporting. Pair meters with gas chromatograph (GC) or validated composition assumptions for mass calculations.

Steam systems in power and refining

For steam balance and energy accounting, vortex and DP with temperature/pressure compensation dominate. Pay attention to wetness fraction, superheat level, and correct enthalpy reporting if you’re feeding an energy management system.

Standards, compliance, and hazardous areas

- Standards & proving: Custody transfer relies on API/AGA/ISO standards, prover loops, and master meters. Expect meter factors, uncertainty budgets, and traceable calibration.

- Hazardous areas: Select transmitters and flow electronics certified for the site (e.g., Class I, Div. 1/2, ATEX/IECEx).

- Materials: Wetted parts must match the service—sour service may require NACE MR0175/ISO 15156 compliance; erosive flow may need hardened, coated, or exotic alloys.

Installation: where accuracy is won or lost

Even the best meter fails if the basics are ignored:

- Straight-run and conditioning: Follow manufacturer and standard guidelines. Use flow conditioners where elbows, tees, or valves are too close.

- Impulse lines (DP): Keep short, sloped, heat-traced if needed, and free of blockages.

- Orientation and support: Prevent vibration, ensure full pipes for liquid meters, and keep meter tubes stress-free.

- Bypass and isolation: Enable maintenance without process downtime; include block-and-bleed for DP systems.

- Instrumentation stack: Pair flow with pressure and temperature transmitters (or integral compensation) for mass and standard volume reporting.

Digitalization: diagnostics, data, and decisions

Today’s transmitters and ultrasonic/Coriolis electronics embed diagnostics that flag coating, bubbles, profile distortion, and signal drift. Tie these into your SCADA/DCS or IIoT platform for:

- Condition-based maintenance: Act on real issues, not calendar dates.

- Automatic meter verification: Reduce pull-and-calibrate cycles while maintaining confidence.

- Edge analytics: Detect leaks (pressure/flow imbalance), compressor surge, and abnormal operations earlier.

Selection quick-map by sector

Upstream

- Well testing/allocation: MPFM or DP+separation; wet-gas Venturi for gas-dominant streams.

- Produced water: Mag meters (conductivity OK).

- Fuel gas: Thermal mass or compensated DP.

Midstream

- Gas transmission custody transfer: Multipath ultrasonic.

- Liquids pipeline: Coriolis (smaller lines) or ultrasonic/turbine + proving for large lines.

- LNG: Ultrasonic for cryogenic flow (with attention to materials and insulation practices).

Downstream (Refining & Petrochem)

- Steam: Vortex or compensated DP.

- Hydrocarbons—process: Coriolis for mass/density and recipe control.

- Loading racks/LACT: PD or Coriolis with custody-transfer approvals.

- Utilities and water: Mag for conductive services.

Keys to a defensible measurement program

- Documented uncertainty: Know your total measurement uncertainty (TMU) for each stream and why it’s acceptable for its purpose.

- Calibration & proving plan: Match intervals to risk and drift behavior. Use master meters and bidirectional provers where appropriate.

- Management of change (MOC): Any shift in fluid, process conditions, or piping geometry should trigger a review of meter assumptions.

- Cyber & power resilience: Harden transmitters, manage firmware, and ensure UPS coverage for flow computers.

- Training & procedures: Clear SOPs for maintenance, zeroing (Coriolis), DP line purging, and verification checks.

Bringing it together

There’s no single “best” meter—only the best fit for your fluid, duty, and business objective. DP shines for rugged, high-temperature service and standardization; turbine and PD are stalwarts for clean custody transfer; Coriolis delivers direct mass and density; ultrasonic rules large lines with low pressure loss; vortex makes steam simple; thermal mass excels for gas utilities and flare; and mag meters own conductive utilities. Layer in good installation practices, compliance with standards, and modern diagnostics, and you’ll have a measurement program that’s credible, cost-effective, and future-ready.

If you’re building a spec, start by listing the fluid envelope, accuracy target, standards, and lifecycle constraints—then shortlist two or three technologies for each service and evaluate on total installed cost and TMU. With that approach, you’ll choose flow measurement equipment for energy sector applications that stands up to audits, delivers reliable control, and protects margin.