What Is Die Cut: From Craft Scrapbooking To Industrial Packaging

Die cutting is a fundamental manufacturing process that shapes materials with astonishing precision and speed. At its core, die cutting involves using a specialized tool – the die – to cut, score, or emboss sheets of material into specific shapes. Understanding its definition, applications, and machinery is crucial for industries ranging from packaging to craft and far beyond.

What is Die Cutting? The Core Definition

The meaning of die cutting revolves around the die itself. Think of a die as a highly engineered stamp or cookie cutter, but designed for industrial or craft use. It’s typically made from sharp steel rule blades bent into a desired shape and mounted on a sturdy board, or crafted as a thin, solid metal form (often bronze or hardened steel) in a process known as die manufacturing. This die is mounted into a machine – ranging from a small manual press to a massive hydraulic cutter – which applies immense pressure, forcing the die through the material to create identical, precise shapes every time.

The Anatomy of a Die: Steel Rule vs. Thin Metal

There are two primary die types:

- Steel Rule Dies: The most common for flexible materials (paper, card, fabric, foam, vinyl, leather, felt, mylar). Sharp steel blades are bent into the design and embedded into a plywood base. Used for boxes, labels, stickers, decals, tags, invitation, envelope, gaskets, and intricate scrapbooking elements.

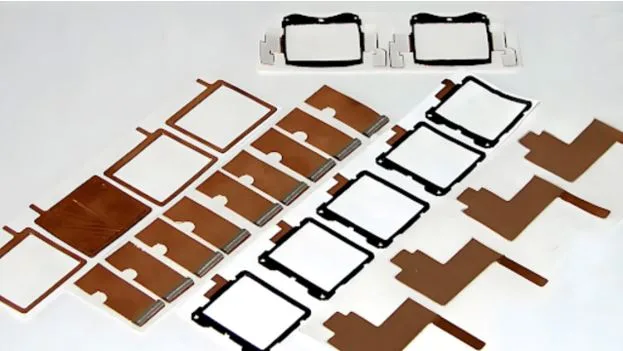

- Thin Metal Dies (Solid Dies): Made from a solid piece of hardened metal (like bronze or steel). Essential for harder materials (plastic, thick card, certain metal foils, pasta dough!) and high-volume runs. Often used in packaging (like container parts), metal shapes, and gaskets.

Die Cutting Machinery: From Craft Tables to Factories

The machine applying the force varies drastically:

- Manual Presses: Ideal for craft, scrapbooking, and short runs. Sizzix machines with their distinctive alphabet and flower sets, Cricut machines (though often using digital blades vs traditional dies), and Ellison machines using template-based letters and shapes fall here. Users make tags, labels, vintage-style letters, christmas ornaments, halloween signs, and butterfly embellishments.

- Hydraulic/Pneumatic Clicker Presses: Common in leather goods (wallet, belt, bag parts), fabric cutting, gaskets, and foam products. They handle thicker materials with power.

- Rotary Die Cutters: Feature cylindrical dies mounted on a wheel. Material feeds through continuously, making them fast and best for high-volume production of labels, tape, packaging (like box shapes), bags, and flexible materials (vinyl, paper). The wheel action ensures speed.

- Laser Cutters/Plotters (Digital Die Cutting): While not using physical dies, machines like Cricut or industrial plotters using Illustrator files replicate the function digitally with blades or lasers. Great for custom, low-volume, or highly intricate design work (logos, decals, signs).

Materials Transformed: What Can Die Cutting Handle?

Die cutting is astonishingly versatile:

- Paper & Cardstock: Invitation, business cards, labels, tags, scrapbooking elements, punch-out letters, christmas cards, envelope liners, pasta shapes (like italian tree or flower designs).

- Adhesive Materials: Vinyl (decals, car signs, stickers), tape, adhesive foam, mylar (used for labels, window decals).

- Fabrics & Textiles: Fabric for apparel, felt for crafts, leather for bags, wallets, belts, snake or horse motifs, intricate lace or flower appliqués.

- Plastics & Films: Plastic sheets for packaging windows, containers, gaskets, magnets, mylar bags.

- Foams & Sponges: Foam for gaskets, seals, padding, craft shapes, costume elements (dragon tails, monster heads).

- Rubber: Gaskets, seals, stamps.

- Thin Metals: Metal foils, bronze shims, aluminum for labels, tags, decorative elements, magnets. (Requires solid dies and powerful presses).

- Specialty: Magnets, pasta, leather, even wood veneer thin sheets.

Critical Techniques: Kiss Cutting vs. Through Cutting

- Kiss Cutting: The die cuts through only the top layer(s) of material (like the vinyl face and adhesive), but not the backing paper or liner. This is essential for stickers, decals, and labels, allowing easy peeling. The die is precisely controlled, often needing half-etch blades.

- Through Cutting: The die cuts completely through the entire material stack. Used for shapes, tags, box parts, fabric pieces, gaskets, punch-outs, scrapbooking elements.

Embossing and Beyond: Adding Dimension

Dies aren’t just for cutting. They create raised or recessed designs:

- Embossing: Uses a male and female die set to create a raised image (letters, logos, flowers, vintage patterns) under pressure. Common on invitation, business cards, book covers.

- Debossing: Creates a recessed image.

- Creasing/Scoring: Uses a blunt rule to create fold lines for boxes, cards, packaging.

- Perforating: Creates tear-off lines using special dotted rules.

Why Die Cutting? The Business Advantages

Die cutting offers compelling benefits:

- High Speed & Volume: Once the die is made, production is extremely fast, making it cheap per unit for large runs.

- Unmatched Precision & Consistency: Every cut piece is identical, crucial for packaging, gaskets, labels, and electronics parts.

- Complex Shapes: Creates intricate designs impossible with standard cutting tools (flowers, butterfly wings, tree silhouettes, complex alphabet letters, vein patterns in leather).

- Material Efficiency: Nests shapes closely on the sheet to minimize waste.

- Versatility: Handles an immense range of materials and thicknesses.

- Durability: Steel rule and solid dies last for thousands, even millions, of impressions.

Applications Across Industries: Where You’ll Find Die Cuts

- Packaging: Boxes (pizza box, window boxes), container inserts, bags, folding cartons, tape. Die cutting creates the part that folds into the final container.

- Labels & Stickers: Product labels, barcode labels, vinyl decals (car decals, window signs), adhesive tags. Kiss cutting is key here.

- Printing & Publishing: Business cards, invitation, book covers, greeting cards, envelope, folders, vintage reproduction elements.

- Automotive & Industrial: Gaskets, seals, foam insulation, metal shims, magnets, protective films, decals, signs.

- Textiles & Apparel: Fabric pieces for clothing, leather components for bags and wallets, felt crafts, wristbands, appliqués (flower, butterfly).

- Crafting & Scrapbooking: The heart of Sizzix, Cricut, and Ellison machines. Creating letters, flowers, christmas ornaments, halloween decorations, vintage embellishments, tags, stamps, butterfly cutouts, tree shapes, alphabet sets, felt animals. Punches are simple hand-held dies.

- Signage: Vinyl letters and logos for windows, car graphics, metal signs.

- Electronics: Insulating foam, mylar shields, adhesive tape shapes, gaskets.

- Food Industry: Pasta shapes (tree, flower, bow tie), intricate food decorations.

Craft Revolution: Sizzix, Cricut, and the Home Market

The difference between industrial and craft die cutting is scale and accessibility. Companies like Sizzix (known for its Big Shot press and vast sets of alphabet, flower, and vintage dies) and Cricut (pioneering digital die cutting with Illustrator-compatible software) brought this powerful technology to home crafters. Ellison machines, often used in schools, rely on template-based letters and shapes. This revolution allows anyone to make professional-looking cards, scrapbooking layouts, invitation, tags, home decals, and christmas decorations with incredible precision. Cheap materials like paper, card, and felt are easily transformed.

The Process: From Design to Finished Part

- Design: Created in Illustrator or CAD software, defining the shape, letters, logo, score lines, and kiss cut lines.

- Die Manufacturing: The digital design is translated into a physical die. For steel rule, blades are bent and mounted. For solid dies, intricate machining or chemical etching is used.

- Material Setup: The chosen sheet material (paper, vinyl, fabric, metal) is loaded onto the machine.

- Cutting/Embossing: The die is positioned, the press cycles, applying tons of pressure. The cutter (wheel on rotary machines, platen on presses) forces the die through/into the material.

- Weeding: Removing excess material from around the cut shapes, especially for stickers, decals, and intricate craft pieces.

- Finishing: Further steps like folding (box assembly), adhesive application, printing, or packaging.

Conclusion: The Enduring Power of Precision

Die cutting, from its roots in vintage industrial presses to the modern Cricut on a craft table, remains an indispensable technology. Its ability to produce identical, complex shapes at high speed and low cost per unit will ensure its place in businesses ranging from global packaging giants to the Etsy seller making custom stickers. Whether creating the window in a box, the gasket sealing an engine, the vinyl letter on a car, the leather part of a wallet, the pasta tree for dinner, or the felt flower for a scrapbooking page, die cutting is the quiet force making precision shapes a tangible reality across countless materials and industries. Understanding its definition, machinery, and best use cases is key to unlocking its potential for fast, cheap, and high-quality production.