Why Choose a China Pleated Filter Cartridge Manufacturer as Your Trusted Supplier

In the global filtration market, pleated filter cartridges have become an essential component in ensuring clean water, pure air, and high-quality industrial processes. From water treatment and food processing to pharmaceuticals and microelectronics, these filters play a vital role in achieving precise and consistent filtration performance.

As global demand for high-quality filter cartridges continues to rise, China has rapidly emerged as one of the world’s most reliable and cost-effective suppliers. Many international buyers, distributors, and engineering companies now source directly from Chinese pleated filter cartridge manufacturers—and for good reasons.

This article explores why choosing a China-based pleated filter cartridge manufacturer as your trusted supplier could be the smartest decision for your business.

1. The Global Rise of China’s Filtration Industry

Over the past two decades, China has transformed from a low-cost manufacturing hub into a global leader in precision filtration technology. Chinese manufacturers are no longer just producing generic filter elements; they are now developing high-performance pleated filter cartridges designed for demanding industrial applications.

This progress is fueled by:

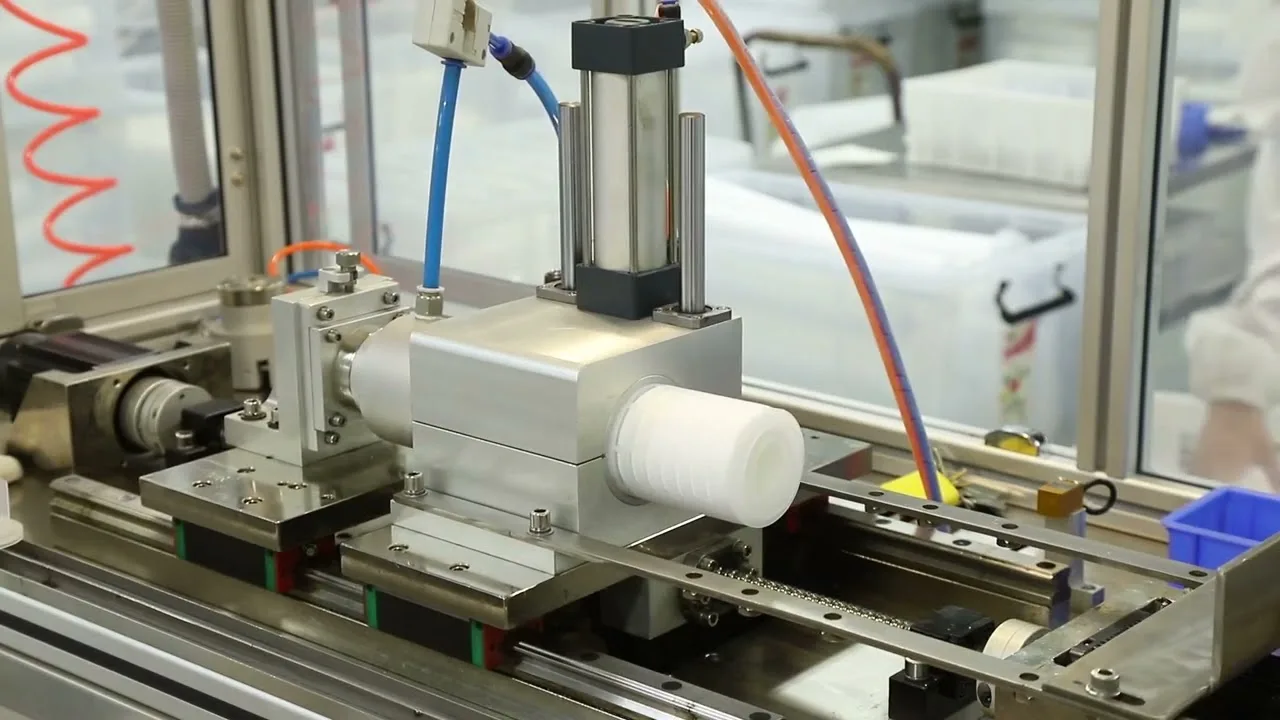

- Advanced production technology: Many factories have introduced automated pleating machines, ultrasonic welding, and cleanroom assembly lines.

- R&D innovation: Leading Chinese manufacturers now invest heavily in developing PTFE, PES, PVDF, and Nylon filter cartridges with high temperature and chemical resistance.

- International standards compliance: ISO 9001, FDA, and CE certifications have become standard across top-tier Chinese filter manufacturers.

As a result, China’s filtration products are now recognized globally for quality, reliability, and competitive pricing.

2. Cost Efficiency Without Compromising Quality

One of the biggest advantages of working with a China pleated filter cartridge supplier is the excellent cost-to-performance ratio.

Chinese factories benefit from:

- Economies of scale: Massive production capacities reduce per-unit costs.

- Efficient supply chains: Integrated raw material sourcing and logistics minimize overhead.

- Lower labor and operation costs: Compared to Western countries, China maintains a more favorable production cost structure.

However, lower cost does not mean lower quality. Many Chinese manufacturers maintain strict quality control processes, perform bubble point tests, integrity tests, and pressure resistance tests, and use imported membranes and polypropylene materials to ensure reliability.

This combination of affordable pricing and consistent quality gives global buyers a competitive edge in their local markets.

3. Strong Export Experience and Global Service Capability

Another key reason to choose a Chinese pleated filter cartridge factory is their rich experience in international trade.

Most of these manufacturers have been exporting for over 10 years, supplying to regions including:

- Europe and the UK

- The United States and Canada

- The Middle East

- Southeast Asia and India

- Latin America and Africa

They are familiar with export documentation, Incoterms (FOB, CIF, DDP), and custom clearance procedures, ensuring that overseas orders are handled smoothly.

Many suppliers also provide:

- OEM & ODM services (custom logo and packaging)

- Flexible minimum order quantities (MOQ)

- Fast lead times and shipping support

For global distributors or integrators, this level of professionalism is critical to maintaining stable supply chains and meeting project deadlines.

4. Advanced Manufacturing and Testing Capabilities

Leading pleated filter cartridge manufacturers in China operate with state-of-the-art facilities.

Their workshops typically include:

- Automatic pleating and cutting lines

- Ultrasonic welding and thermal bonding systems

- Cleanroom assembly to prevent contamination

- Advanced integrity testing machines for bubble point and diffusion tests

These advanced technologies ensure precise pleat spacing, strong bonding, uniform flow distribution, and high dirt-holding capacity.

In addition, many manufacturers produce a wide range of filter media options such as:

- PP (Polypropylene) pleated filter cartridges

- PTFE (Polytetrafluoroethylene) pleated filter cartridges

- PES (Polyethersulfone) pleated filter cartridges

- PVDF (Polyvinylidene fluoride) pleated filter cartridges

- Nylon and glass fiber media

Each type is carefully tested to meet the specific requirements of water purification, beverage filtration, chemical processing, and biotechnology.

5. Customization and Flexibility

Unlike large Western corporations that often impose strict order requirements, Chinese pleated filter cartridge suppliers are highly flexible. They can quickly adjust production to meet customized specifications.

Customization options include:

- Filter length and diameter (5”, 10”, 20”, 30”, 40”)

- Micron ratings (0.1 µm – 50 µm)

- End cap types (DOE, SOE 222/226, flat or fin)

- Gasket materials (EPDM, Viton, NBR, silicone, PTFE)

- Brand labeling and private packaging

This flexibility makes them ideal partners for OEM projects or distributors looking to build their own brand.

Furthermore, small and medium buyers benefit from low MOQs, which allows them to test market response without large upfront investment.

6. Global Buyers Trust Chinese Manufacturers

In recent years, international filtration companies, EPC contractors, and plant integrators have developed long-term partnerships with China pleated filter cartridge suppliers.

This trust is built on:

- Consistent product quality over time

- Stable communication and support

- Competitive pricing models for bulk orders

- After-sales service, including technical documentation and testing certificates

Some Chinese manufacturers have even become OEM suppliers for Western brands, proving their capability to meet demanding global standards.

As one European distributor noted, “Working with a Chinese pleated filter cartridge manufacturer has allowed us to reduce costs by 30% while maintaining the same quality level.”

7. Comparison: China vs. Other Manufacturing Countries

When selecting a pleated filter cartridge supplier, buyers often compare China with other countries such as the United States, Germany, Japan, and India. Each has its strengths, but in today’s competitive environment, China provides the most balanced combination of quality, cost, and scalability.

| Criteria | China | Western Countries | India / Southeast Asia |

| Price | ✅ Highly competitive due to efficient supply chains | ❌ Higher due to labor & overhead | ✅ Moderate but often inconsistent |

| Technology | ✅ Advanced manufacturing with imported membranes | ✅ Excellent but expensive | ❌ Generally lower precision |

| Lead Time | ✅ Fast, with flexible scheduling | ❌ Longer due to smaller factories | ⚠️ Moderate |

| Customization | ✅ High flexibility, OEM/ODM accepted | ⚠️ Often limited | ✅ Flexible but variable quality |

| Export Experience | ✅ Mature international trade system | ✅ Strong but costlier logistics | ⚠️ Developing stage |

As the table shows, China consistently offers the best balance between performance, price, and service reliability. This makes it a strategic choice for importers seeking long-term cooperation and stable margins.

8. Technological Innovation and R&D Capability

The perception that Chinese factories only focus on low-cost mass production is outdated. Today, leading China pleated filter cartridge manufacturers invest heavily in R&D and innovation.

They cooperate with universities, research institutes, and international membrane technology suppliers to continuously improve filter performance. Key innovations include:

- Enhanced hydrophilic and hydrophobic membrane treatments for higher flow rates.

- Antibacterial and anti-static coatings for food and electronic applications.

- Thermally bonded structures for improved integrity under pressure.

- Multi-layer gradient filtration design for longer service life.

Some factories even develop in-house test labs equipped with bubble point testers, air diffusion testers, and particle retention instruments. These efforts ensure that each batch of cartridges meets strict international performance criteria.

This continuous innovation helps Chinese manufacturers compete head-to-head with established global brands.

9. Case Studies: Global Clients Benefiting from Chinese Suppliers

To illustrate the real-world advantages of sourcing from China, consider the following examples:

Case 1 – Water Treatment Plant in South America:

A municipal water treatment company was using European pleated filters, which were high in quality but costly. After switching to a Chinese PP pleated filter cartridge supplier, they reduced costs by 35% while maintaining the same filtration efficiency and durability. The supplier also provided customized labeling for their regional brand.

Case 2 – Food & Beverage Manufacturer in the Middle East:

The client required PES and PTFE pleated filters with FDA compliance. Their Chinese partner provided complete documentation, including material safety data sheets and certificates of conformity, meeting export inspection standards. The result: faster delivery and a more competitive price-to-performance ratio compared to local alternatives.

Case 3 – Semiconductor Facility in Southeast Asia:

A microelectronics manufacturer needed high-purity filters for ultrapure water systems. Their chosen PVDF pleated filter cartridge manufacturer in China provided membranes tested under ISO Class 7 cleanroom conditions, ensuring compatibility with high-precision applications.

These case studies demonstrate that China’s pleated filter cartridge factories are not just suppliers—they are long-term technical partners.

10. Building Long-Term Partnerships with Chinese Manufacturers

When choosing a pleated filter cartridge supplier, one-off transactions may solve immediate needs—but long-term partnerships bring sustainable value.

Chinese manufacturers often aim to grow together with their clients, offering:

- Stable pricing and flexible terms for repeat orders.

- Product updates and technical improvements based on feedback.

- After-sales support, including installation guidance and testing protocols.

Many overseas distributors have maintained 5–10 years of cooperation with their Chinese partners. These long-term relationships foster trust, mutual growth, and business stability—critical factors in the filtration industry where quality consistency is paramount.

11. How to Identify a Reliable Chinese Pleated Filter Cartridge Manufacturer

With thousands of filter factories across China, not all are equal. Buyers should evaluate suppliers carefully before establishing cooperation. Here are key steps:

- Check Certifications:

Ensure the manufacturer holds ISO 9001, FDA, CE, or SGS certifications for quality assurance.

- Inspect Production Facilities (Virtually or On-Site):

Ask for videos or photos of cleanrooms, pleating machines, and test equipment.

- Request Product Samples and Test Reports:

Evaluate filtration efficiency, pressure drop, and integrity before bulk orders.

- Review Export History:

Check if they have exported to your target markets and can provide references.

- Assess Communication and Responsiveness:

A professional manufacturer will reply quickly, offer technical support, and guide you through shipping documentation.

- Compare Total Value, Not Just Price:

The cheapest option is not always the best. Focus on the combination of performance, stability, and service.

Selecting the right partner ensures smooth cooperation, predictable delivery schedules, and high customer satisfaction.

12. The Future of China’s Pleated Filter Cartridge Industry

Looking ahead, the Chinese filtration industry is poised for steady growth and technological transformation.

Key trends include:

- Green manufacturing and eco-friendly materials.

- Automation and digital monitoring in production lines.

- Integration of AI-based inspection systems for defect detection.

- Expansion into medical and biopharmaceutical filtration sectors.

As sustainability becomes a global priority, China’s ability to provide both cost-effective and environmentally responsible filtration solutions will strengthen its global position even further.

13. Conclusion: The Smart Choice for Global Buyers

Choosing a China pleated filter cartridge manufacturer is not merely a cost-saving decision—it’s a strategic business move.

By partnering with the right supplier, you gain:

- High-quality filtration performance at competitive prices

- Reliable delivery and technical support

- Flexible customization and OEM capabilities

- Proven experience in global trade and export compliance

Whether you are an equipment manufacturer, distributor, or end-user in water treatment, pharmaceuticals, or food processing, China offers the optimal combination of value, technology, and service.

Working with a trusted Chinese pleated filter cartridge factory allows your business to enhance product competitiveness, reduce procurement risks, and expand globally with confidence.