Why Equipment Decisions Matter in Business Operations

How many times have you heard someone at work say, “It’s just a tool,” like that somehow makes the thing irrelevant? Until it breaks. Until it delays production. Until your staff spends more time fixing it than using it. The tools a business relies on aren’t background noise. They shape how work gets done. In this blog, we will share how equipment decisions impact business operations in ways you can’t afford to overlook.

It Starts With What You Rely On Most

Every business depends on something mechanical, digital, or industrial to keep things moving. Whether it’s forklifts, HVAC systems, point-of-sale hardware, compressors, or specialized machinery, the foundation of daily output comes down to whether your gear is working as expected. And in 2024, the margin for error has shrunk.

Supply chains remain unpredictable. Replacement parts that used to arrive in two days now take two weeks. Skilled technicians are booked out, and many small businesses can’t absorb downtime the way large operations can. It’s a tighter game now. What used to be a one-hour delay could now stretch into a day or two, setting off a domino effect across your schedule, payroll, and customer expectations.

So when a business leans on equipment, it has to do more than work—it has to hold up under pressure, operate efficiently, and stay easy to maintain. One reason many commercial setups continue to use reliable, proven components is because they can’t afford to play roulette with performance. That’s what puts models like the Impco Model J in a different category. It’s not about bells and whistles. It’s about showing up every day, functioning cleanly with low emissions, and supporting fuel systems that need consistency, not flair.

Durability and parts availability aren’t just technical perks—they’re operational safeguards. Choosing gear that holds up under stress reduces the number of decisions you’ll have to make later when something fails at the worst possible moment. And those moments will come, because no matter what industry you’re in, work finds a way to test your setup.

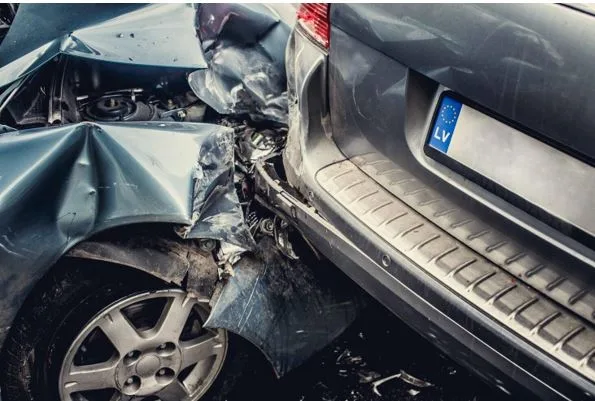

Downtime Doesn’t Ask for Permission

If there’s one thing that rattles a business faster than a bad review, it’s a machine that suddenly stops mid-task. Unexpected downtime isn’t just inconvenient—it can kill momentum. Orders pile up, crews stand around waiting, clients get impatient, and what started as a $500 repair starts looking more like $5,000 in lost opportunity. You can’t always prevent equipment from breaking, but you can control how fragile your systems are to begin with.

In sectors like logistics, construction, or field services, even a brief shutdown has ripple effects. Fuel costs go up, delivery timelines fall apart, and crews lose billable hours. When a single part can take a whole unit offline, the decision to go with cheaper components up front tends to feel shortsighted in hindsight. There’s no honor in saving a few dollars only to lose thousands later when it matters most.

More businesses are catching on. You see it in the shift toward building redundancy into fleets, investing in preventative maintenance, and standardizing around brands that still manufacture support parts after five years. None of this is exciting. It doesn’t show up in flashy startup pitches or trending business threads. But it’s what keeps the day-to-day from collapsing.

Resilient operations aren’t about buying the most expensive gear. They’re about knowing what you can’t afford to lose, and building around that risk.

Where Cutting Corners Quietly Adds Up

Some of the costliest decisions in business aren’t obvious at the start. They hide in the slow performance drag, the energy inefficiencies, or the slight uptick in repair calls. It’s easy to ignore small signs when you’re busy. But ignoring them creates a setup where waste becomes part of your routine.

Take fuel efficiency, for instance. A unit that burns slightly more propane or diesel might not raise alarms right away, but multiply that over hundreds of hours of use, and it’s suddenly draining more than just a tank. Or consider tools that require frequent recalibration. If your team loses 10 minutes per day dealing with them, that’s nearly an hour of productivity gone each week, per person. It adds up, silently, until you’re running a slower business without even realizing it.

Equipment doesn’t have to fail to cost you. It just has to slow you down.

That’s what separates strategic operations from reactive ones. The smartest businesses aren’t always the ones with the newest tech or the biggest budgets. They’re the ones that understand total cost of ownership—how gear performs over time, what it takes to keep it running, and how much it disrupts when it stops working as expected.

No One Notices the Right Gear Until It’s Gone

You know equipment decisions were solid when nobody talks about them. The right compressor doesn’t get mentioned. The efficient pump isn’t the topic of morning meetings. The heating unit that works on the coldest day of the year doesn’t earn praise. It just does what it’s supposed to do. The moment it stops doing that? Suddenly everyone has opinions.

That silence is the goal. Great gear blends into the background because it supports everything without drawing attention. That kind of reliability creates focus. Your team isn’t distracted. Your managers aren’t fielding complaints. You get to run the business, not react to it.

As the economy pushes companies to do more with less—less time, less staff, less room for error—there’s even more pressure to make these kinds of infrastructure decisions count. Whether you’re operating on a shoestring budget or investing in a long-term setup, the wrong gear always ends up costing more.

In the end, equipment isn’t just a line item on a spreadsheet. It’s a choice that echoes through how your team functions, how your customers experience your service, and how sustainable your business really is. Decisions made quietly in back offices and supply rooms tend to define the loudest moments of success—or the most inconvenient failures.

If your gear works so well that no one notices it, that’s not a lack of recognition. That’s a win. And those wins add up more than anyone ever gives them credit for.