Why PLA Remains the Most Popular 3D Printing Material for Everyday Projects

Introduction

Polylactic acid, commonly known as PLA, has earned a strong reputation as one of the most accessible and widely used materials in desktop 3D printing. Across Canada, it is frequently chosen by hobbyists, educators, and small businesses seeking reliable results without complex setup requirements. Its steady rise in popularity is closely linked to ease of use, visual quality, and predictable performance across a wide range of printers.

PLA stands out because it lowers the barrier to entry for new users while still offering enough consistency for repeat projects. Canadian consumers often prioritize materials that deliver dependable results with minimal waste, especially when ordering supplies online. PLA meets these expectations by providing smooth extrusion, stable layer bonding, and a forgiving printing process that reduces common errors.

Availability also plays an important role in its continued demand. PLA is produced in a broad range of colours and finishes, making it suitable for decorative items, prototypes, and educational models. Regional sourcing considerations matter as well, particularly for buyers comparing quality, price, and shipping reliability. Discussions around PLA Filament in Lebanon often highlight how localized supply chains influence access to consistent materials, a challenge seen in many regional markets.

Beyond technical benefits, PLA aligns with lifestyle driven creativity. It supports rapid idea testing, artistic exploration, and functional problem solving at home or in classrooms. As 3D printing becomes more integrated into everyday life, PLA remains a practical choice that balances performance, affordability, and accessibility for a growing Canadian audience.

What PLA Is and Why It’s Widely Used

PLA is a thermoplastic polymer derived primarily from renewable plant based sources such as corn starch or sugarcane. This origin differentiates it from petroleum based plastics and contributes to its reputation as an approachable and modern material. In practical terms, PLA softens at relatively low temperatures, allowing it to flow smoothly through standard printer nozzles without excessive heat.

One reason PLA is widely used across Canada is its forgiving nature during printing. It adheres well to common build surfaces and shows minimal warping compared to other materials. This stability reduces setup time and makes it easier for users to achieve successful prints on entry level and mid range machines.

PLA also produces consistent surface quality. Layers bond cleanly, resulting in sharp details and smooth finishes that suit visual models and display pieces. These characteristics make it popular in schools, maker spaces, and design studios where appearance matters as much as function.

From a usability standpoint, PLA does not require enclosed printers or advanced environmental controls. This accessibility supports its adoption in homes and small workshops. Canadian buyers often value materials that integrate easily into existing setups without costly upgrades.

While PLA is not suited for high heat or heavy load applications, its balance of reliability, appearance, and ease of handling explains why it continues to dominate everyday printing projects. It remains a practical starting point and a dependable long term option for many users.

Print Quality and Surface Finish Advantages

PLA is widely recognized for producing clean, visually appealing prints with minimal post processing. Its consistent flow characteristics allow layers to stack evenly, resulting in sharp edges and smooth contours. For Canadian users creating models, décor, or prototypes, this aesthetic reliability is a significant advantage.

Surface finish quality is influenced by how evenly a material extrudes and cools. PLA cools at a predictable rate, reducing defects such as rough textures or uneven layer lines. This makes it suitable for items intended for display or presentation, where appearance is a priority. Even at standard print speeds, PLA maintains clarity in fine details.

Color reproduction is another strength. PLA pigments tend to distribute evenly, delivering vibrant and uniform tones. Matte, glossy, and specialty finishes are commonly available, expanding creative options without changing print settings. This versatility supports artistic projects and branding prototypes.

Print quality also contributes to efficiency. Fewer defects mean fewer reprints, which saves time and material. For educators and small businesses in Canada, this reliability supports tighter project timelines and controlled costs.

In discussions about global sourcing and material quality, comparisons involving PLA Filament in Lebanon often focus on consistency and finish standards. These considerations mirror what Canadian buyers seek when evaluating suppliers and ordering online.

Overall, PLA’s surface finish advantages reinforce its role as a dependable material for everyday use. It delivers professional looking results while remaining accessible, making it a preferred choice for users who value both form and function.

Temperature Requirements and Printer Compatibility

PLA is highly regarded for its low temperature printing requirements, which make it suitable for a broad range of consumer and professional 3D printers commonly used across Canada. Most PLA filaments print reliably at nozzle temperatures between 190 and 220 degrees Celsius. These moderate temperatures help minimize strain on printer components, extending the life of the equipment and reducing the risk of jams or blockages. While a heated bed can improve first layer adhesion, it is not strictly required for successful printing, allowing users with basic setups to achieve consistent results with minimal adjustment. This flexibility contributes to PLA’s reputation as an accessible and beginner-friendly material.

Lower temperature operation also offers safety benefits and energy efficiency. Printers warm up faster, consume less electricity, and experience less thermal stress over time, which is advantageous for home users, schools, and maker spaces where machines may run for several hours daily. Unlike materials that require enclosed chambers to prevent warping, PLA prints effectively in open environments. This characteristic reduces hardware costs and simplifies setup, especially for Canadians seeking reliable solutions without investing in advanced or specialized printers.

PLA’s compatibility extends beyond just hardware considerations. It flows smoothly through standard brass nozzles and adheres well to common build surfaces, such as glass, PEI sheets, or coated print plates. Users rarely require specialized upgrades or experimental setups to begin printing successfully. Many regional suppliers, including 3dscapers.com, prioritize providing consistent, high-quality PLA filaments designed to integrate seamlessly with existing machines. By offering reliable materials, these suppliers help reduce setup frustrations and improve printing success rates, particularly for first-time users or educational environments.

Overall, PLA’s combination of low temperature requirements, broad printer compatibility, and ease of use explains its widespread adoption. It allows Canadian users to focus on creativity, project experimentation, and productivity rather than constant calibration. For everyday projects, PLA’s accessibility remains one of its strongest and most appealing advantages.

Strength Limitations and Practical Use Cases

PLA is a versatile material but has inherent limitations that affect how it should be applied in practical projects. While it provides excellent rigidity and smooth surface finishes, PLA is relatively brittle compared to alternatives such as ABS or PETG. This brittleness makes it unsuitable for applications that require high impact resistance or structural durability under stress. It is best employed for projects where visual quality, accuracy, and ease of printing take precedence over mechanical strength.

Heat sensitivity is another important factor to consider. PLA softens when exposed to elevated temperatures, which limits its use for outdoor items, automotive interiors, or parts subjected to hot conditions. For indoor objects, decorative items, educational models, or light-use organizational tools, PLA maintains its shape and performs reliably under normal ambient conditions. Users must evaluate their project environment to ensure the material aligns with functional requirements.

PLA excels in a variety of practical use cases, particularly those centered on visual appeal and design validation. Its dimensional accuracy and clean layer bonding make it ideal for prototypes, display pieces, educational tools, and small decorative objects. These applications are popular in Canadian homes, schools, and small businesses where aesthetics, clarity, and ease of production are key priorities. PLA allows designers to test concepts quickly, visualize ideas, and create functional mockups without the need for expensive or industrial-grade filaments.

Understanding PLA’s limitations helps reduce material waste and improves print success. Choosing the right material for each application ensures durability and avoids premature failure. While it may not replace stronger plastics in demanding conditions, PLA continues to provide dependable results for everyday low-stress projects. Its balance of accessibility, surface quality, and ease of use makes it a practical, cost-effective choice for a wide range of users.

PLA for Hobbyists, Students, and Small Businesses

PLA plays a pivotal role in supporting creativity, education, and entrepreneurship across Canada. Hobbyists appreciate its ease of use, reliability, and low-maintenance requirements, which allow them to explore personal projects and intricate designs without frequent troubleshooting. Students benefit from its predictable performance, enabling them to focus on learning design principles, CAD modeling, and the fundamentals of 3D printing rather than technical frustrations. Small businesses rely on PLA for rapid prototyping, product mockups, and visual demonstrations that communicate concepts effectively to clients.

For beginners, PLA reduces common barriers to entry. Its forgiving characteristics,such as low warping potential and straightforward adhesion,allow new users to achieve consistent results even on entry-level printers. This encourages experimentation, fosters confidence, and supports the development of printing skills without wasting material or time. Educational institutions, from primary schools to universities, benefit from PLA’s safety profile. Lower operating temperatures and minimal emissions make it suitable for classrooms, labs, and workshops where multiple students share printers, helping instructors integrate hands-on learning into curricula efficiently.

Small businesses leverage PLA to produce cost-effective prototypes, packaging samples, or marketing displays. Its clean finish and dimensional accuracy enhance the professionalism of final models without requiring extensive post-processing. This efficiency saves both time and resources, supporting budget-conscious operations.

PLA’s versatility extends to a wide range of everyday projects, from decorative items to functional organizational tools. By combining ease of use, safety, and aesthetic appeal, PLA serves as a foundational material for creative exploration and practical prototyping. Its accessibility ensures that students, hobbyists, and small business operators alike can incorporate 3D printing into their workflows, learning environments, and creative pursuits. As 3D printing continues to expand in popularity across Canada, PLA remains the material of choice for those seeking dependable performance with minimal complexity.

Environmental Impact and Biodegradability Myths

PLA is often marketed as environmentally friendly due to its plant-based origins, but its real-world sustainability is more complex. While derived from renewable resources such as corn starch or sugarcane, PLA does not readily biodegrade under typical household or landfill conditions. Proper composting generally requires industrial facilities with high temperatures and controlled conditions, meaning PLA should not be assumed disposable or compostable in everyday contexts.

For environmentally conscious Canadian users, this distinction is crucial. PLA should be viewed as a durable plastic with specific end-of-life considerations rather than an inherently sustainable alternative. Responsible use, recycling where possible, and minimizing waste remain essential for reducing environmental impact. PLA production typically results in lower greenhouse gas emissions compared to petroleum-based plastics, further contributing to its appeal. However, sustainability ultimately depends on efficient design, material use, and printing practices.

Users can improve environmental outcomes by optimizing designs, reducing failed prints, and reusing or recycling scrap filament. Minimizing material waste has a far greater effect than relying solely on the plant-based origin of the material. Thoughtful planning, efficient workflows, and reuse strategies help mitigate environmental concerns while maintaining the benefits of PLA printing.

Understanding these realities supports informed, responsible decisions. PLA provides many advantages,low-temperature printing, ease of use, aesthetic quality,but its environmental profile is conditional. Canadian consumers benefit most when combining its practical benefits with sustainable printing habits, ensuring that PLA remains a viable material choice for creative, educational, and functional projects without compromising environmental responsibility.

Color Variety and Creative Applications

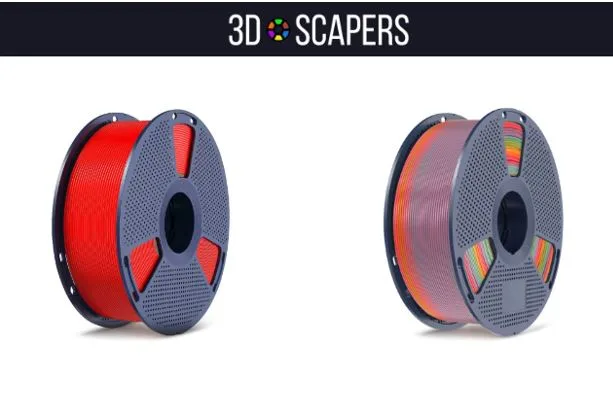

One of PLA’s greatest strengths is its broad spectrum of color and finish options, which makes it ideal for creative and decorative projects. Canadian hobbyists, educators, and small businesses often choose PLA specifically for its ability to produce visually striking models without requiring post-processing or painting. Standard colors such as red, blue, and green are readily available, while specialty options include translucent, metallic, glow-in-the-dark, and even multi-color blends that expand design possibilities. This versatility supports both functional prototypes and visually impressive display pieces.

Beyond color, PLA’s adaptability allows users to experiment with various textures and finishes. Matte, glossy, and semi-transparent filaments enable designers to create products that reflect specific aesthetic requirements. For example, small businesses can produce packaging prototypes with a professional finish, while educators can craft models that clearly illustrate concepts in science or art classes. Artists and makers also use PLA for custom figurines, décor, and jewelry prototypes where precise visual fidelity is critical.

PLA’s creative applications extend into rapid prototyping. Designers and engineers can test color-coded parts for clarity in assembly or educational tools, enabling visual differentiation of components. Its predictable extrusion and consistent surface quality ensure that even complex shapes are rendered with detail, helping users visualize and refine ideas quickly.

Overall, the wide array of colors and finishes enhances PLA’s appeal across multiple audiences. It allows Canadian users to combine functionality with creativity, transforming everyday printing projects into engaging and visually appealing outputs. By selecting PLA with specific color and finish characteristics, users can achieve professional results without additional tools or materials. This capability reinforces PLA’s position as the material of choice for both practical and artistic projects, making it a versatile solution for home, school, and small business applications.

Comparing PLA with PETG and ABS

While PLA excels in accessibility and surface finish, it is important to understand how it compares to other popular filaments such as PETG and ABS. PETG offers greater impact resistance and flexibility than PLA, making it suitable for functional parts that may endure moderate stress or require moisture resistance. PETG is often chosen for water containers, mechanical components, or outdoor items where durability is important, although it generally requires slightly higher print temperatures and slower cooling to avoid stringing.

ABS, in contrast, provides superior heat resistance and toughness, making it suitable for automotive components, tools, or objects exposed to elevated temperatures. However, ABS presents challenges for beginners, including warping, strong odors during printing, and a requirement for enclosed build spaces or controlled environments. Compared to PLA, ABS demands more precise printer calibration and is less forgiving of errors in bed adhesion or temperature management.

PLA stands out for its ease of use, low-temperature printing, and ability to produce clean, detailed surfaces with minimal setup. Unlike PETG and ABS, it rarely requires an enclosed printer or advanced cooling adjustments. Its consistency and predictability make it ideal for rapid prototyping, decorative objects, and educational projects, while PETG and ABS are better suited for functional or industrial applications.

Canadian buyers ordering online often weigh these factors against project requirements. PLA remains preferred for everyday printing due to its beginner-friendly nature and aesthetic quality, while PETG and ABS serve specific functional niches. Understanding these distinctions ensures that users select the most suitable filament for their intended purpose, balancing appearance, strength, and reliability effectively.

Storage and Longevity of PLA Filament

Proper storage is crucial for maintaining PLA filament quality over time, as exposure to moisture and environmental fluctuations can negatively affect performance. PLA is hygroscopic, meaning it absorbs water from the air, which can lead to bubbling, poor layer adhesion, and stringing during printing. In Canada, where humidity levels vary seasonally, controlling storage conditions is particularly important for ensuring consistent results and long-term usability.

Airtight containers with desiccant packs are commonly used to protect spools from moisture. Filament drying ovens or heated storage cabinets can restore slightly damp filament before use. Storing filaments away from direct sunlight and temperature extremes further preserves their structural integrity. Even simple precautions, such as keeping spools in sealed bags with silica gel, can significantly extend shelf life and reduce waste.

Proper handling also contributes to longevity. Avoiding sharp bends, tangles, or kinks prevents breakage and ensures smooth feeding through the printer. Placing spools on secure holders reduces friction and supports uniform extrusion. For Canadian consumers who order filament online, especially in bulk, following these practices ensures consistent print quality and reduces material waste.

By taking these steps, users can maintain PLA’s performance for months or even years. Consistent storage practices support reliable printing, minimize troubleshooting, and maximize value from each spool. Careful handling reinforces PLA’s accessibility and helps hobbyists, students, and small businesses maintain productivity and achieve high-quality results across diverse projects.

Buying Considerations for Local and Regional Markets

Selecting the right PLA filament involves more than simply choosing a color or the lowest price. Canadian users must consider factors like supplier reliability, regional availability, and material consistency to ensure high-quality prints. Understanding these considerations helps reduce failed prints and wasted materials. Local and regional sourcing can influence shipping times, costs, and overall project efficiency. By making informed choices, consumers can achieve reliable results and enjoy a smoother 3D printing experience.

Key Buying Considerations for PLA

- Quality and Consistency: High-quality PLA is identified by uniform filament diameter, consistent coloration, minimal impurities, and even spool tension. These characteristics reduce printing defects, such as stringing or layer adhesion problems, which can compromise the finished product. Ensuring consistent quality supports reliable printing and minimizes material waste.

- Supplier Reputation and Support: Choosing suppliers with proven reliability helps ensure predictable filament performance. Platforms like 3dscapers.com offer detailed specifications and expert guidance, allowing users to prepare their printers properly. Access to responsive customer support also helps resolve issues quickly, saving time and reducing frustration.

- Regional Availability: Buying from nearby distributors can reduce shipping times, lower costs, and improve the likelihood that filament arrives in optimal condition. Regional sourcing also facilitates access to local expertise and faster replacement or troubleshooting when needed. This approach enhances convenience and helps maintain continuous workflow.

- Detailed Specifications: Reliable suppliers provide comprehensive information about temperature ranges, printer compatibility, and filament properties. These specifications allow users to match filament to their specific printer and project requirements. Understanding these details reduces trial and error and improves print success rates.

- Project and Long-Term Considerations: Evaluating PLA options in the context of both current projects and long-term usage ensures maximum value. Considering storage conditions, intended applications, and durability helps users select materials suited for personal and professional needs. Thoughtful buying decisions promote efficiency, satisfaction, and consistent results.

Making informed purchasing decisions is essential for Canadian PLA users. Evaluating quality, supplier reputation, regional availability, and detailed specifications ensures reliable prints and reduces wasted material. Considering both short-term projects and long-term applications maximizes the value of each filament purchase. Using reputable platforms and suppliers helps users maintain smooth workflow and access guidance when needed. Ultimately, thoughtful selection allows PLA to continue being a dependable, versatile material for everyday 3D printing projects.

Conclusion

PLA remains one of the most accessible, reliable, and versatile 3D printing materials for users across Canada. Its ease of use, low temperature printing, and broad compatibility make it suitable for beginners, hobbyists, students, and small businesses alike. PLA consistently delivers smooth surfaces, accurate detail, and dependable results, supporting creative exploration and practical prototyping without unnecessary complexity.

The material’s limitations, including brittleness and heat sensitivity, are easily managed by matching PLA to appropriate applications. Display items, educational models, decorative pieces, and light functional components represent ideal projects, while more demanding tasks may require PETG or ABS. Understanding PLA’s characteristics ensures optimal print quality and reduces material waste, enhancing both productivity and sustainability.

Proper storage, moisture management, and handling further extend PLA’s performance and lifespan. For Canadian users, following best practices ensures consistent results regardless of seasonal humidity changes or extended storage periods. Selecting reliable suppliers like 3dscapers.com guarantees access to high-quality PLA, supporting smooth printing and creative confidence.

Color variety, specialty finishes, and predictable extrusion behavior make PLA ideal for artistic, functional, and educational applications. Its balance of affordability, visual quality, and user-friendliness reinforces its dominance as the material of choice for everyday 3D printing. Canadian buyers who understand these factors can maximize value, minimize errors, and enjoy the full potential of desktop 3D printing.

For those seeking dependable, versatile, and high-quality PLA, browsing the shop or ordering online in Canada ensures consistent results, expands creative possibilities, and provides reliable materials for projects both large and small. PLA continues to offer an optimal combination of performance, accessibility, and aesthetic appeal, making it an essential tool for makers at every level.