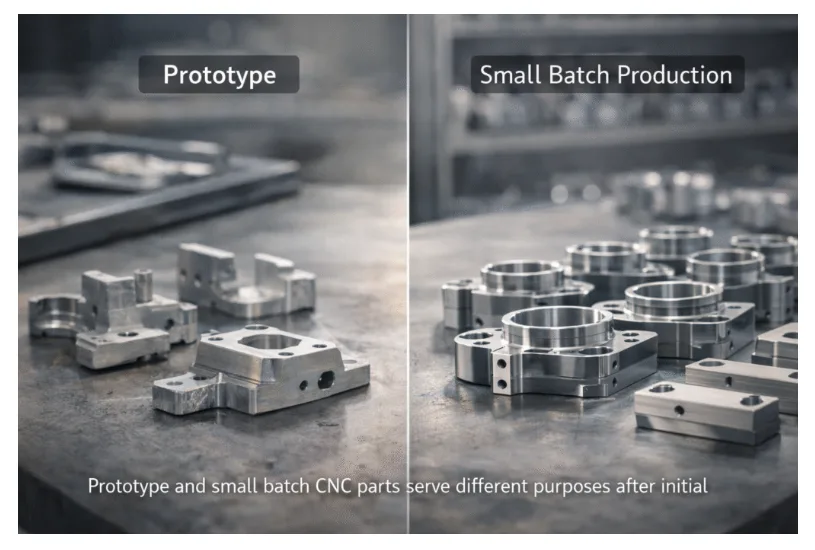

Why Small Batch CNC Machining Is the Smart Choice After Prototyping

Introduction

Once a prototype is finished, the most mistake-prone phase of a project usually begins.

Choosing the wrong manufacturing approach at this point is rarely just a budget issue. It can lock a product into decisions that are difficult to undo later—affecting cost, timelines, and even whether the project can realistically move forward.

If you are deciding how to continue testing, validating, or delivering a product without taking on unnecessary risk, this article focuses on one question: are you actually ready for mass production, or is a small-batch CNC phase the smarter next step right now?

The discussion below does not argue for speed or scale. Instead, it looks at how to make a production decision that fits the current level of uncertainty—so progress continues without closing off better options too early.

From Prototyping to Production: Where the Real Challenges Begin

In the early stages of development, decisions tend to be relatively simple. Prototypes exist to answer a basic question: does the design work at all? Change is expected, and iteration is part of the process.

That clarity fades once a prototype performs as intended.

At this point, the product appears viable, yet many factors remain unsettled. Designs may still change. Demand is often unclear. Order volumes are usually estimates at best. From here on, each manufacturing decision carries a multiplier effect on cost, schedule, and risk.

This is often the first moment when teams seriously face the production question—not whether to move forward, but how to do so without committing to a path that cannot easily be reversed.

From that perspective, the challenge is not machining capability. It is how to move smoothly from prototyping to production while design details, demand assumptions, and cost expectations are still evolving. When a rigid approach is chosen too early, later adjustments become slower, more expensive, and harder to justify.

This explains why the post-prototype phase tends to be where projects either stabilize—or quietly derail.

Why Moving Straight to Mass Production Is Often a Risk Decision

During prototyping, iteration is manageable. A dimension changes, a material is swapped, another sample is made. These adjustments are expected and relatively contained.

Mass production changes the nature of decisions entirely.

Production requires commitment—not only to cost, but to design stability, process selection, delivery schedules, and demand forecasts. Immediately after prototyping, most of those variables are still in motion.

A common mistake at this stage is treating a working prototype as proof of production readiness. In reality, the gap between those two states is not manufacturing capability, but certainty.

If a prototype still requires explanation, it is not ready to be scaled.

Ask a few uncomfortable questions:

- Has the design been validated under real-use conditions?

- Are critical dimensions truly stable?

- Is demand predictable enough to justify fixed production assumptions?

If the answer to any of these is “not yet,” moving directly into mass production is less a step forward than a gamble.

This stage is not about maximizing efficiency. It is about avoiding decisions that reduce flexibility before uncertainty has been resolved.

Why Small Batch CNC Manufacturing Works as a Transition

Once the risks of early mass production become clear, teams often look for a way to keep moving forward without forcing irreversible commitments.

This is where small batch CNC manufacturing becomes relevant.

At this stage, small batch production is not simply about producing fewer units. It is about limiting the strength of commitment while uncertainty still exists. Designs can be tested under realistic conditions, issues surface naturally, and refinements happen without mistakes being amplified through scale.

For many teams, small batch manufacturing becomes more than a temporary workaround. It functions as a controlled transition—one that supports learning while preserving momentum.

In practice, teams often turn to experienced suppliers of samll batch CNC machining parts not because they are ready for scale, but because they need production-quality components that behave like final parts, without locking themselves into rigid decisions too early.

Most importantly, small batch CNC manufacturing preserves optionality. Design changes, material adjustments, and incremental improvements remain possible. Compared to highly fixed production setups, adjustments stay manageable rather than disruptive.

Seen this way, small batch CNC manufacturing acts as a buffer—not a delay, but a way to approach production with clearer information and fewer regrets.

Why CNC Machining Is Often Chosen for Small Batches

Among small batch options, the approaches that gain traction at this stage tend to share one characteristic: they tolerate uncertainty well.

CNC machining is frequently selected not because it is the most advanced method available, but because it aligns with the realities of post-prototype decision-making.

When designs are still evolving and demand is not fully defined, processes that require heavy upfront investment are harder to justify. CNC machining avoids that barrier while remaining flexible enough to accommodate ongoing changes.

It also produces parts that closely resemble final production components. Materials, tolerances, and structural behavior are often representative of what will follow at scale. This makes feedback from CNC-produced batches far more informative than insights drawn from early prototypes alone.

This does not mean CNC machining is always the right answer. For designs that are frozen and volumes that are highly predictable, other methods may be more efficient. But when uncertainty remains high, ease of adjustment, reversibility, and validation often matter more than achieving the lowest possible unit cost.

When Small Batch CNC Machining Makes Sense—and When It Doesn’t

Small batch CNC machining is not a universal solution. Whether it makes sense depends less on technology and more on the current state of the product.

It often fits best when designs are largely defined but still subject to refinement, when demand exists but is difficult to forecast, or when parts must behave like production components without committing to full-scale manufacturing.

Teams preparing for testing programs, pilot runs, or limited deliveries frequently fall into this category. They need consistency and realism, but not the rigidity that comes with mass production.

A simple way to frame the decision is this:

If you cannot confidently freeze your design, forecast demand, and commit to tooling at the same time, you are not late to production — you are early.

At the same time, small batch CNC machining is less suitable when designs are fully locked, demand is stable, and scaling efficiency is the dominant concern. In those cases, remaining in a small batch phase may slow progress rather than support it.

The decision, ultimately, is about timing—not technology.

What to Look for in a Small Batch CNC Partner

Once a direction is chosen, execution becomes the real test.

At this stage, price alone rarely tells the full story. More important is whether a supplier understands the uncertainty inherent in this phase and can adapt as conditions change.

Communication often matters more than specifications. How a supplier responds when you say, “this feature may change,” can reveal far more than any capability list. Responsiveness, clarity, and a willingness to engage with evolving requirements tend to define whether progress feels smooth—or frustrating.

Continuity also matters. Small batch production is rarely the end goal. The experience gained during this phase should support what comes next, rather than forcing a reset later on.

Choosing a partner who understands that trajectory can reduce friction well beyond the first batch.

Conclusion: Choosing the Right Next Step Matters More Than Speed

After prototyping, it is easy to feel pressure to move quickly. Delaying production can feel like falling behind.

Speed matters, but irreversible decisions matter more.

In practice, projects are more often slowed by heavy commitments made at the wrong time than by careful, staged progress. Locking into a production method before uncertainty is resolved tends to limit options rather than create momentum.

A smart choice is not always the fastest one. It is the one that fits the current stage of the product and preserves the ability to adapt. When viewed through that lens, small batch CNC machining becomes less of a compromise and more of a deliberate step toward sustainable production.