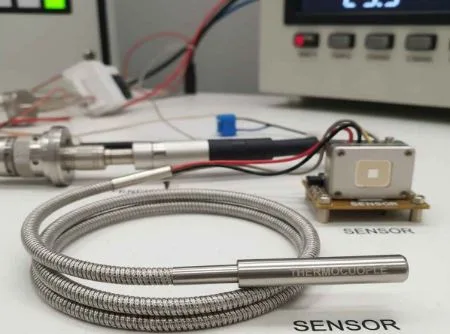

Why Thermocouple & Sensor Malaysia Matter in Modern Manufacturing?

Modern manufacturing depends on precise measurement systems to maintain speed, accuracy, and efficiency. Industrial processes now operate under tighter tolerances and higher performance expectations. Thermocouple & Sensor Malaysia solutions have become essential for maintaining control across complex production environments. These technologies support stable operations in industries ranging from electronics to heavy manufacturing.

As Malaysia strengthens its position as a regional manufacturing hub, reliable sensing technology is increasingly important. Manufacturers must meet both local and international production requirements without compromising quality. Thermocouples and sensors provide the real-time data needed to support this demand. Their role continues to expand as production systems become more advanced.

Modern Manufacturing Needs

Today’s manufacturing facilities require constant monitoring to ensure processes remain within defined parameters. High-speed automation and advanced machinery leave little room for error. Thermocouple and sensor Malaysia systems help manufacturers maintain visibility over critical operations. This visibility allows quick adjustments before small issues become costly problems.

Modern production also depends on reliable thermal solutions working alongside sensing technology. Temperature regulation systems such as Heaters Malaysia solutions support stable manufacturing environments. When combined with accurate sensors, they ensure consistent process conditions. This integration is essential for meeting modern manufacturing expectations.

Role of Temperature Control

Temperature plays a crucial role in shaping material properties during production. Incorrect temperature levels can weaken materials or disrupt chemical reactions. Thermocouples provide accurate readings even in extreme industrial conditions. This reliability makes them ideal for continuous manufacturing processes.

In Malaysia’s manufacturing sector, temperature control supports consistent production outcomes. Industries such as food processing and electronics rely heavily on stable thermal conditions. Sensors help maintain these conditions throughout the production cycle. This ensures that final products meet required specifications.

Accuracy and Consistency

Accuracy is essential for maintaining repeatable manufacturing results. Inconsistent sensor data can lead to poor adjustments and unstable operations. Thermocouple & Sensor Malaysia solutions are designed to deliver precise measurements over time. This precision supports dependable decision-making across production lines.

Consistency is equally important for meeting customer expectations. Manufacturers must produce identical results across large production volumes. Reliable sensors reduce variability in critical processes. This leads to improved output uniformity and operational confidence.

Supporting Automation Growth

Automation relies heavily on accurate data to function efficiently. Machines and control systems depend on sensor feedback to make real-time adjustments. Thermocouples provide temperature data that enables automated responses. This supports seamless operation without constant human supervision.

Malaysia’s move toward Industry 4.0 has increased demand for intelligent sensing systems. Automated factories require sensors that integrate easily with digital platforms. Thermocouple and sensor Malaysia technologies support this integration. They enable smarter, faster, and more adaptive production environments.

Improving Product Quality

Product quality depends on maintaining controlled production conditions. Variations in temperature or pressure can affect final product performance. Sensors ensure these variables stay within acceptable limits. This reduces defects and improves overall product reliability.

Manufacturers in Malaysia compete in both local and global markets. High-quality products strengthen brand reputation and customer trust. Thermocouples help maintain stable conditions during critical stages of production. This consistency directly contributes to better product outcomes.

Safety and Risk Reduction

Manufacturing environments often involve high temperatures and hazardous materials. Without proper monitoring, these conditions can pose serious risks. Thermocouples detect abnormal temperature changes early. This allows preventive action before incidents occur.

Sensor systems also protect expensive machinery from damage. Overheating or pressure spikes can lead to equipment failure. Thermocouple & Sensor Malaysia solutions help prevent such scenarios. This contributes to safer workplaces and reduced operational risks.

Meeting Industry Standards

Manufacturers must comply with strict industry and regulatory standards. Many certifications require documented process control and monitoring. Sensors provide the data needed to demonstrate compliance. This is essential for audits and quality assurance.

Malaysia-based manufacturers often supply international markets. Global clients expect adherence to recognized quality standards. Reliable thermocouples help maintain controlled production environments. This supports long-term business relationships and market credibility.

Real-Time Data Advantage

Real-time data allows manufacturers to respond instantly to process changes. Instead of waiting for end-of-cycle inspections, issues are detected early. Thermocouples continuously transmit temperature information. This supports proactive process management.

Real-time monitoring also improves operational efficiency. Data trends help identify inefficiencies and optimization opportunities. Thermocouple & Sensor Malaysia systems enable data-driven decision-making. This leads to faster responses and improved productivity.

Long-Term Cost Savings

Accurate sensing technology reduces material waste and rework. Early detection of issues prevents large-scale production losses. Thermocouples help avoid unnecessary shutdowns and repairs. Over time, this results in significant cost savings.

High-quality sensors also have longer service lives. This reduces replacement and maintenance expenses. Manufacturers in Malaysia benefit from improved equipment reliability. These long-term savings strengthen overall operational profitability.

Enhancing Process Control

Process control is essential for maintaining stable production conditions. Sensors provide continuous feedback on key variables. Thermocouples ensure temperature-sensitive processes remain controlled. This stability improves yield and operational efficiency.

Better process control also reduces variability in output. Manufacturers can maintain consistent quality across production batches. Thermocouple and sensor Malaysia solutions support precise adjustments. This leads to predictable and optimized manufacturing performance.

Local Expertise Value

Local suppliers understand Malaysia’s industrial landscape and requirements. They offer solutions tailored to regional manufacturing conditions. Thermocouple & Sensor Malaysia providers deliver faster support and technical guidance. This improves system implementation and reliability.

Working with local experts also enhances system customization. Manufacturers benefit from easier integration and ongoing assistance. Local knowledge ensures compliance with regional standards. This partnership approach strengthens long-term operational success.

Why SH Heating Leads the Way?

SH Heating Sdn. Bhd. stands out as a trusted provider of industrial heating and sensing solutions in Malaysia. The company focuses on delivering high-quality thermocouples and sensors for demanding manufacturing environments. Its solutions are designed to meet accuracy, durability, and performance requirements. This commitment makes it a preferred partner for many industrial sectors.

With strong local expertise, SH Heating Sdn. Bhd. understands the specific needs of Malaysian manufacturers. The company offers technical support, customization, and reliable after-sales service. Its products help clients improve process control and operational efficiency. This customer-focused approach positions the provider as an industry leader.

Conclusion

Thermocouples and sensors play a vital role in modern manufacturing environments. They support accuracy, automation, safety, and quality across production processes. In Malaysia, these technologies enable manufacturers to meet global demands. Their importance will continue to grow as industries evolve.

Investing in reliable Thermocouple & Sensor Malaysia solutions ensures long-term operational stability. Manufacturers gain better control, reduced risk, and improved efficiency. These benefits contribute to sustainable growth and competitiveness. Modern manufacturing success depends heavily on accurate sensing technology.