Wrapping a Motorcycle: Protection, Flexibility, and Value

In recent years, wrapping a motorcycle has developed rapidly. Many people’s first thought when they hear about wrapping a motorcycle is, “it looks good.” But in reality, its function goes far beyond just changing the appearance.

Wrapping a motorcycle has become a practical way to protect paintwork, personalize the exterior, and help maintain the vehicle’s value.

With the rising prices of new motorcycles and increasing demand for customization, wrapping a motorcycle with vinyl films is no longer just a temporary solution. With the right materials, it is a long-term solution for riders, repair shops, and even racing teams.

What exactly is wrapping a motorcycle?

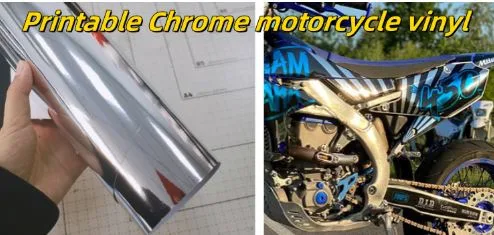

Simply put, wrapping a motorcycle means applying a thin, flexible vinyl film to the surface of the bike.

It can be applied to painted surfaces or exposed parts.

This film is specifically designed for complex curved surfaces. It can stretch and rebound without easily deforming.

Motorcycles are very different from cars. Fuel tanks, fairings, fenders, and side panels have small surface areas and many curves, making wrapping a motorcycle more difficult. Therefore, the quality requirements for vinyl materials used when wrapping a motorcycle are higher.

Good materials stretch evenly and maintain stable colors. Poor quality materials might look good immediately after wrapping a motorcycle, but they will quickly shrink and peel at the edges. These problems become more pronounced under high temperatures and vibrations.

The protective function of wrapping a motorcycle

Many people underestimate the protective value of wrapping a motorcycle. In fact, daily riding constantly wears down the paintwork.

Stones, dust, insects, fuel splashes, and UV rays all gradually damage the paint.

Over time, scratches accumulate, the color fades, and the bike looks old. If you plan to sell the bike later, its value will decrease.

Wrapping a motorcycle acts like a protective shell. It absorbs minor scratches and reduces direct damage. Cleaning is also easier after wrapping a motorcycle.

When replacement or removal is needed, the film can be peeled off completely. In most cases, the original paintwork remains in good condition.

Thickness isn’t the key. The material is.

Some riders believe that thicker films are better for wrapping a motorcycle.

This is not actually the case. The truly important factor is the material composition.

Wrapping a motorcycle means the material must survive extremely demanding conditions:

- High temperatures near the engine and exhaust

- Environmental exposure such as rain, snow, road salt, and sunlight

- Frequent washing and cleaning

- Constant vibration, especially at high speeds

Only a stable polymer substrate combined with a suitable adhesive system can meet these requirements. Good materials are less likely to become brittle or yellow over time. When wrapping a motorcycle with quality film, removal is also cleaner, with no adhesive residue.

Professional installers prioritize stability

Material consistency is crucial for professionals who specialize in wrapping a motorcycle. Stable performance saves time during installation. Lower failure rates and fewer rework jobs result in higher customer satisfaction.

The market is changing

The market for wrapping a motorcycle is still growing rapidly. It is no longer driven only by color or design trends.

More people now see wrapping a motorcycle as a practical solution. From manufacturers and distributors to professional installers, attention is shifting toward material performance rather than just appearance.

Wrapping a motorcycle is no longer just a service.

It is a solution based on material reliability. Stability and predictability are essential for long-term use.

Wrapping a motorcycle is a mature solution

Wrapping a motorcycle is no longer just about decoration. With the right materials and proper installation, it protects paintwork and helps preserve value.

Wrapping a motorcycle allows for flexible personalization without long-term commitment. The original condition can be restored at any time. Today, material performance sits at the core of the industry. Durability, ease of installation, and real-world value are more important than ever before.