4 Signs Your PTO Clutch Needs to be Replaced

Are you noticing some odd behavior from your machinery? It could be your PTO clutch crying out for help!

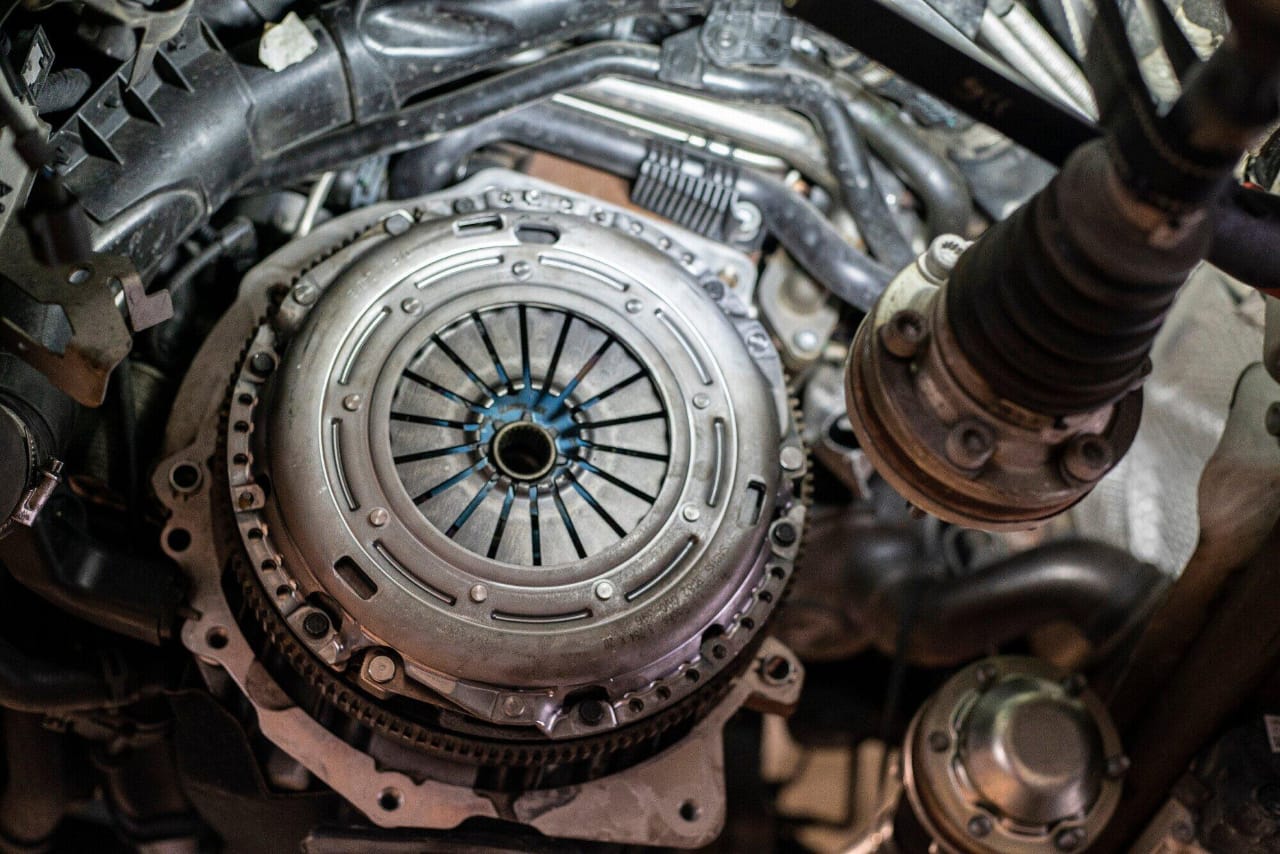

A malfunctioning or worn-out PTO (Power Take-Off) clutch can lead to equipment failure. But, don’t panic! We’re here to guide you.

In this article, we’ll walk you through four telltale signs that your PTO clutch may need a replacement. Stay tuned and ensure your equipment keeps running smoothly and efficiently.

- Excessive Vibration

One of the common warning signs that your PTO clutch may be in trouble is excessive vibration. It’s normal for heavy machinery to shake a little when in use. But, if your equipment starts vibrating more than usual, it could mean your PTO clutch is wearing out.

This often happens when the clutch’s internal components become worn or damaged. The excessive vibration is due to an imbalance in the clutch’s operation. If you’re feeling more shake, rattle, and roll than normal, it’s time to investigate your PTO clutch.

- Difficulty in Engaging the Clutch

Another clear sign of a PTO clutch needing replacement is when you face trouble engaging the clutch. Usually, a healthy clutch will engage smoothly when powered.

But, if your PTO clutch is acting up, you might struggle to get it working. You might notice a delay, or it might not engage at all. This issue often stems from worn-out internal components, indicating it’s time for a clutch replacement.

A faulty clutch can hinder your equipment’s performance, affecting your work progress. It’s essential to address it to keep your machinery running efficiently. You can check out John Deere power equipments here for reliable and durable PTO clutch replacement options.

- Inferior Output

Is your machinery not working as good as it used to? That could be a third cue that your PTO clutch needs to be replaced.

The purpose of a PTO clutch is to transfer power from your equipment’s engine to another part of the machine. If there’s a problem with the clutch, the power transfer won’t be as efficient. This means your machinery won’t perform at its best.

For example, if you’re mowing grass, a faulty PTO clutch might make the blades turn slower, leaving your lawn looking unequally cut. It’s like trying to run a race with a flat tire – you won’t get far! If you notice your machinery’s output dropping, it might be the right time to replace the PTO clutch.

- Overheating

Overheating is another big red flag that your PTO clutch needs to be replaced. When a clutch is working too hard, it can get hot. Really hot.

If your PTO clutch is running hot, it’s working too hard. This could be because of wear and tear, or maybe it’s just old. Either way, an overheated clutch isn’t an efficient clutch.

It can even be a fire hazard in extreme cases! Remember, it’s always better to be safe than sorry. So if you notice your machinery running hotter than normal, it’s time to check the PTO clutch. It might be time for a new one.

Don’t ignore this sign! Your machinery, and your safety, depend on it.

Is It Time for a New PTO Clutch?

A well-functioning PTO clutch is key to efficient machinery. Don’t ignore signs like unusual vibrations, clutch engagement issues, poor performance, or overheating. Spotting these signs early on can save you from bigger troubles later.

Keep your machinery in top shape by replacing your PTO clutch promptly when needed. Stay alert and keep your equipment running smoothly!

Please take a look at our blog for more educational articles.