Understanding Radiation Sterilization: Process, Applications, and Benefits

Sterilization plays a crucial role in healthcare, pharmaceuticals, food safety, and industrial applications. It ensures that products are free from harmful microorganisms such as bacteria, fungi, and viruses. Among the various sterilization methods available—such as heat, chemical, and filtration—radiation sterilization has emerged as one of the most effective and widely used techniques. But many still ask, What Is Radiation Sterilization? and how does it differ from conventional approaches?

This article provides a detailed overview of radiation sterilization, including its principles, techniques, applications, advantages, and future potential.

What Is Radiation Sterilization?

Radiation sterilization is a process that uses controlled doses of ionizing radiation to destroy microorganisms on or within products. Unlike chemical sterilization or heat-based methods, it does not require high temperatures or toxic substances, making it ideal for sensitive materials. Radiation works by damaging the DNA or RNA of microorganisms, preventing them from replicating and rendering them harmless.

The most common radiation sources used for sterilization are:

- Gamma radiation (typically from Cobalt-60 isotopes)

- Electron beam (E-beam) radiation

- X-ray radiation

Each method has its specific advantages and is chosen based on the type of product, packaging, and production requirements.

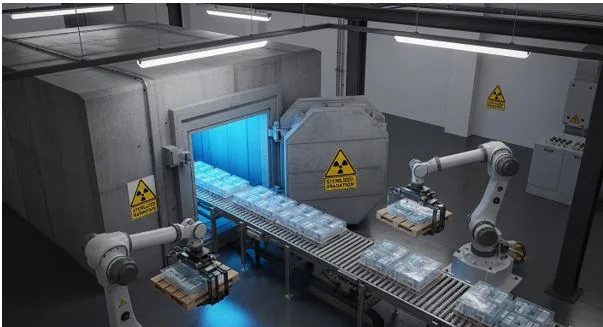

How Radiation Sterilization Works

The process of radiation sterilization involves several steps:

- Preparation – Products are packaged in their final form, as the process can penetrate packaging materials.

- Exposure – The packaged products are exposed to a controlled dose of ionizing radiation.

- Microbial Inactivation – The radiation damages the DNA of microorganisms, stopping their ability to reproduce.

- Validation and Testing – The sterilization dose is validated using standards (such as ISO 11137) to ensure effectiveness.

Because radiation can penetrate packaging and reach all surfaces uniformly, the process ensures thorough sterilization without compromising product integrity.

Types of Radiation Sterilization

Gamma Radiation

Gamma sterilization uses high-energy gamma rays from Cobalt-60. It has high penetration power, making it suitable for dense or bulk products. It is commonly used in medical devices and pharmaceutical products.

Electron Beam (E-beam) Radiation

E-beam sterilization uses high-energy electrons generated by an accelerator. While its penetration is shallower than gamma radiation, it is faster, more energy-efficient, and environmentally friendly. It works well for small or medium-sized products.

X-ray Radiation

X-ray sterilization uses high-energy X-rays generated by machine sources. It combines the deep penetration of gamma radiation with the efficiency of E-beam systems. It is particularly useful for large or irregularly shaped items.

Applications of Radiation Sterilization

Radiation sterilization is widely used across multiple industries because of its effectiveness and adaptability:

Healthcare and Medical Devices

- Sterilizing surgical instruments, syringes, catheters, and implants

- Ensuring single-use medical supplies are safe and pathogen-free

Pharmaceuticals

- Sterilizing pharmaceutical raw materials and finished products

- Decontaminating packaging materials such as blister packs and bottles

Food Industry

- Extending shelf life by reducing spoilage microorganisms

- Controlling pathogens in spices, herbs, and packaged foods

- Reducing the risk of foodborne illnesses

Cosmetics and Personal Care

- Sterilizing raw ingredients used in creams, lotions, and powders

- Preventing microbial contamination in finished cosmetic products

Industrial Applications

- Sterilization of laboratory equipment and packaging materials

- Surface decontamination of sensitive instruments

Advantages of Radiation Sterilization

Cold Process

Since radiation does not involve high temperatures, it is ideal for sterilizing heat-sensitive materials such as plastics, polymers, and certain pharmaceuticals.

Penetration Capability

Gamma and X-ray radiation can penetrate packaging and product layers, ensuring sterilization without the need to unpack or expose items.

Efficiency and Reliability

Radiation sterilization is consistent, with well-defined standards and validation protocols that ensure reliability.

Reduced Chemical Use

Unlike ethylene oxide (EtO) sterilization, radiation does not involve harmful gases or toxic residues, making it safer and more environmentally friendly.

Faster Turnaround

E-beam radiation, in particular, provides rapid sterilization, making it suitable for high-volume production lines.

Scalability

Radiation systems can handle everything from small batches to large industrial volumes, providing flexibility for manufacturers.

Limitations of Radiation Sterilization

While radiation sterilization offers numerous benefits, it also comes with some limitations:

- Material Compatibility: Certain polymers may degrade or discolor when exposed to radiation.

- Initial Investment: Setting up radiation facilities, particularly gamma or X-ray, requires significant investment and regulatory compliance.

- Dosage Control: Overexposure can damage product integrity, while underexposure may fail to achieve sterility.

- Safety Requirements: Handling radiation sources requires strict safety protocols and specialized infrastructure.

Comparison with Other Sterilization Methods

- Heat Sterilization: Effective but unsuitable for heat-sensitive materials.

- Chemical Sterilization: Uses gases like EtO but leaves toxic residues and requires long aeration times.

- Filtration: Suitable for liquids and gases but cannot be used for solid items.

Radiation sterilization stands out because it is versatile, residue-free, and applicable to a wide variety of products.

Regulatory Standards

Radiation sterilization is regulated globally to ensure safety and effectiveness. Standards include:

- ISO 11137: Guidelines for validation and routine control of radiation sterilization for medical devices

- FDA (U.S. Food and Drug Administration) regulations for medical products and food

- WHO (World Health Organization) guidelines for safe application in pharmaceuticals and food safety

Manufacturers must validate processes according to these standards before products are released to the market.

The Future of Radiation Sterilization

As industries grow and demand for sterile products increases, radiation sterilization is set to play an even greater role. Future trends include:

- Greater adoption of E-beam technology due to its speed, lower energy costs, and environmental advantages

- Integration with automation and IoT for precise dosage monitoring and real-time process validation

- Expansion in food safety as global regulations encourage pathogen control and longer shelf life

- Advanced material research to improve radiation resistance in packaging and sensitive products

These developments will make radiation sterilization more accessible, efficient, and environmentally sustainable.

Conclusion

Sterilization is essential to ensure the safety of medical, pharmaceutical, food, and cosmetic products. Radiation sterilization has become one of the most trusted and effective methods because of its ability to penetrate packaging, maintain product integrity, and eliminate harmful microorganisms without heat or chemicals. Understanding What Is Radiation Sterilization? helps businesses and consumers appreciate its role in protecting health and improving product quality.

By leveraging gamma rays, E-beams, or X-rays, industries achieve reliable, scalable, and environmentally friendly sterilization. While there are limitations regarding material compatibility and setup costs, the advantages far outweigh the drawbacks. As technology advances, radiation sterilization will continue to evolve, driving innovation across healthcare, food safety, and beyond.