Applications of Wired Glass and Why Use It?

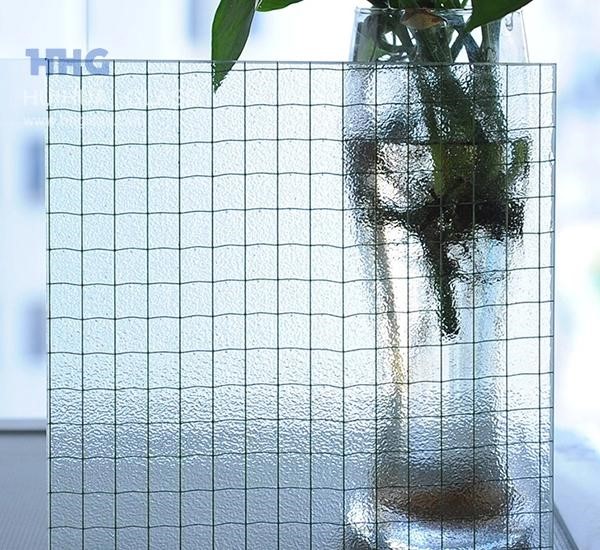

Wired glass is a type of glass that contains a wire mesh embedded within it. This design provides extra strength and safety compared to ordinary glass, making it useful in various applications where both fire resistance and impact resistance are needed. Here’s why wired glass is used and where it is commonly applied:

Composition and Manufacturing

Wired glass is produced by embedding a thin metal wire mesh within the glass during the manufacturing process. The process typically involves:

- Wire Mesh Placement: A grid of wire (often made from steel or other durable metals) is placed between two layers of semi-molten glass.

- Glass Formation: The glass is then pressed and rolled together with the wire mesh inside, bonding the glass layers and the wire into a single, solid piece.

- Cooling: The combined material is cooled, solidifying into a sheet of glass with the wire mesh encased in the middle.

This manufacturing process results in a glass that is stronger and safer than ordinary glass, thanks to the reinforcing wire.

Advantages of Wired Glass

1. Fire Resistance:

- Containment: Wired glass can withstand direct exposure to fire for a period of time, typically up to 45 minutes, depending on the specific product and installation. The wire mesh helps prevent the glass from breaking apart quickly, which helps contain flames, smoke, and hot gases, limiting their spread.

2. Safety in Shattering:

- Controlled Breakage: When wired glass is broken, the wire mesh holds the fragments in place, reducing the risk of injury from sharp glass shards. This characteristic makes it safer than standard glass, especially in environments where impact is possible.

3. Security:

- Barrier to Intruders: The wire mesh adds an extra layer of difficulty for anyone attempting to break through the glass, making it a good choice for security windows in schools, commercial buildings, and other areas requiring additional protection.

4. Durability:

- Resilience to Damage: The embedded wire makes wired glass more resistant to small impacts and environmental stressors, such as wind or minor debris, compared to plain glass.

5. Aesthetic and Functional:

- Industrial Aesthetics: Wired glass has a distinctive appearance due to the visible wire grid. This makes it a popular choice in certain architectural designs, especially in buildings aiming for an industrial or retro look.

Limitations of Wired Glass

1. Impact Resistance:

- Not as Strong as Modern Alternatives: While wired glass is more resistant to breakage than standard glass, it is less impact-resistant than modern options like tempered glass or laminated glass. Wired glass can break under sufficient force, though the wire mesh will hold the fragments.

2. Visibility Issues:

- Distortion: The wire mesh can cause some visual distortion, which may not be desirable in all applications, particularly where clear visibility is crucial.

3. Safety Regulations:

- Restrictions: In some regions, building codes have restricted the use of wired glass in certain applications, particularly in areas prone to human impact, such as doors and low windows. This is due to the potential for injury if the glass is broken. Modern safety glass alternatives, like tempered or laminated glass, are often required in these locations.

4. Weight and Handling:

- Heavier and More Brittle: Wired glass is generally heavier than regular glass and can be more brittle, making it challenging to handle and install without proper care.

Specific Applications

1. Fire-Rated Assemblies:

- Doors and Windows: Wired glass is commonly used in fire-rated doors and windows. It allows light and visibility while meeting fire safety requirements. These are often found in commercial buildings, stairwells, and corridor walls that require a fire barrier.

2. Skylights:

- Safety in Overhead Glazing: Wired glass is used in skylights to ensure that, in the event of breakage, the glass fragments stay in place, reducing the risk of injury from falling debris.

3. Interior Partitions:

- Offices and Schools: Wired glass is often used in interior partitions and windows in educational institutions and office buildings, providing a combination of safety, fire resistance, and visibility.

4. Industrial and Commercial Buildings:

- Warehouses and Factories: The durability and safety features of wired glass make it ideal for use in industrial settings, where it can withstand the rigors of the environment while providing necessary fire protection.

5. Public Buildings:

- Hospitals and Libraries: Wired glass is used in public buildings where both fire safety and impact resistance are critical. For instance, it can be found in doors, windows, and partitions in hospitals, libraries, and government buildings.

6. Historic and Decorative Uses:

- Restoration Projects: Wired glass is sometimes used in the restoration of historic buildings to maintain the original appearance while meeting modern safety standards. Its industrial aesthetic also makes it a popular choice for decorative purposes in modern architecture.

Regulatory Considerations

1. Building Codes:

- Compliance: Wired glass must meet specific standards and building codes, especially in terms of fire ratings and impact safety. In some cases, it is required to be used in conjunction with additional protective measures, such as film coatings, to enhance its safety features.

2. Legal Restrictions:

- Impact Safety: In many jurisdictions, building codes have evolved to restrict or even prohibit the use of wired glass in locations where it might be impacted by people, such as in schools or hospitals. Modern alternatives like laminated glass, which can offer similar fire resistance and greater impact safety, are often preferred in these areas.

Conclusion

Wired glass remains a valuable material in construction, particularly for its fire-resistant properties and ability to provide a safer form of glazing compared to standard glass. While it has limitations, especially concerning impact resistance, its use in fire-rated assemblies, industrial settings, and specific design aesthetics makes it a versatile choice in many architectural applications. However, due to evolving safety standards, its use in certain areas may be limited, and modern glass alternatives are increasingly favored in situations where safety is a paramount concern.

HHG is a professional glass manufacturer and glass solution provider that includes a range of tempered glass, laminated glass, textured glass, and etched glass. With more than 20 years of development. There are two produce lines of pattern glass, two lines of float glass, and one line of restoration glass. our products 80% ship to overseas. All our glass products have strict quality control and are carefully packed in strong wooden cases. Ensure you receive the finest quality glass safely on time.

More Details: www.hhglass.com