Understanding Photoelectric Proximity Sensors: The Future of Non-Contact Sensing

Today, in the industrial field, there are non-contact sensing technologies that help change approaches to automation, safety and quality assurance. Of all the above mentioned technologies, photoelectric proximity sensors are acknowledged to be particularly effective methods of inspecting objects. While ideal, these are unlike other sensors that employ contact as their primary function because photoelectric proximity sensors use light as its primary method for detection and are very effective and accurate. Such sensors are getting trendy in the manufacturing, logistics, and packaging industry where sensing plays a vital role for accuracy and efficiency. Hence, for those organizations that want to remain relevant it is important for them to comprehend how such sensors operate and the benefits that are associated with its usage. OMCH boasts a variety of gleaming photoelectric proximity sensors that meet the needs of clients in line with industrial automation to bring aspects of their operations to better levels for businesses to stand high.

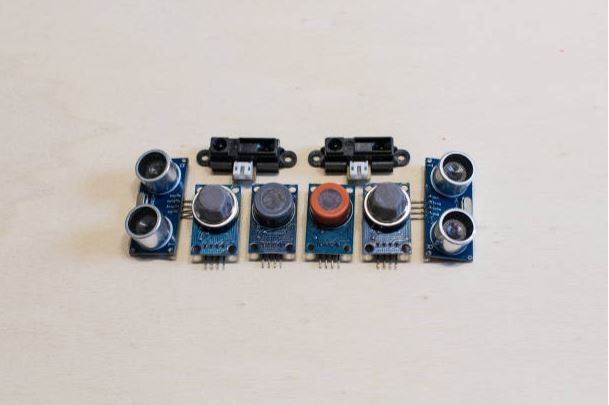

How Photoelectric Proximity Sensors Work and Their Types

The technology of proximity sensors with specific reference to photoelectric operates under the logic of light detection that employs an emitter to generate a light beam that is normally of infrared type to establish detection of the target through changes in the reflection, interruption or blocking by that target. Some of the most known varieties of photoelectric proximity sensors are diffuse, retro-reflective and through-beam. Diffuse sensors operate through the reflected light coming from the body of the object and reflected back to the diffused sensor; thus, the system is good for close object surveillance. Retro-reflective sensors actually employ a reflector to reflect light back to the receiver and an object comes in the way to obstruct this path for getting the signal. Through-beam sensors have one emitter and one receiver and the object breaks the path between them. Every sensor type provides special features, for example, as the through-beam sensor provides exact sensing of distant objects. These various configurations allow OMCH’s line of photoelectric proximity sensors to meet these needs for various automation applications, to deliver the precise detection that these companies require.

Applications of Photoelectric Proximity Sensors

Flexible and highly reliable photoelectric proximity sensors find their place in a number of industries. In manufacturing, these sensors are useful in identification of parts on lines, confirming existence of the object and being part of quality control. For instance, in assembly processes, sensors may be used to identify the placement of parts: issues such as missing or misplaced items will automatically prompt alarms. For the packaging industry, the photoelectric sensors play an important role in counting the products, position and alignment on conveyors for further sorting and packaging. These sensors are also applied in the food and beverages industry where it ‘feels’ items to check for presence without direct contact thus keeping hygienically healthy. In manufacturing, photoelectric sensors make mechanical handling easier to track and sort packages according to automated lines in logistic states. OMCH’s line of sensores de proximidad photoelectrique is tailored to be appropriate for such fast-paced, high-degree of detail industries so that B2B organizations may experience increased levels of operational precision and effectiveness.

Pros of the use of Photoelectric Proximity Sensors

There are numerous advantages associated with photoelectric proximity sensors, which do make this type of sensor highly attractive to the B2B organization. The first is don’t touch the object and methods, thus the chances of damage and wearing of both the sensor and the object it is detecting is negligible. Unlike other forms of detectors that require physical contact with the item or the material in question, this non-invasive detection is perfect for use where the material potentially being detected is delicate. Also, these sensors have high versatility in that they do not need to be changed to monitor both opaque and transparent objects. A feature of photoelectric sensors is that they also allow for long-range object detection; through-beam sensors, for instance, are capable of detecting objects from distances beyond which many other types of sensors would be effective. Another major advantage associated with the sensors is fast and accurate response in that they are capable of sensing fast moving objects without excessive delay and thus very useful in high speed manufacturing applications. These are features that come with OMCH’s photoelectric proximity sensors which guarantee organizations the kind of performance that is satisfactory in the industrial market.

Choosing the Right Photoelectric Proximity Sensor for Your Application

The evaluation criteria for the optimum photoelectric proximity sensor are based on the application type, object characteristics, and operating environment. Whether to use diffuse, retro-reflective, or through-beam sensors, will mostly be informed by the distance, material, and size of the object to be detected. Diffuse sensors are well suited for short range applications featuring first reflection, while retro-reflective sensors are designed for the detection of reflected surfaces at distance ranges in the middle range. Through-beam sensors are better off for long distance utilization, and are perfectly suitable for high speed sensing applications. Other factors affecting sensor performance are also relevant; they include lighting conditions, temperature and exposure to dust or moisture that also come into picture. Few models allow for sensitivity adjustments to allow for transportability in diverse scenarios that complicate the models. OMCH’s photoelectric proximity sensors offer various arrangements for these exact requirements so that B2B corporations can arrange the most suitable solutions for their business, including measurements for traffic, accuracy, swiftness, and reliability.

Conclusion

Applications for the photoelectric proximity sensors cut across industrial processes in automation for non-contact detection that help increase the accuracy of a process as well as the speed of process in the future. When the working principle of these sensors is understood and the right model for each type of application is chosen, this would allow B2B companies to implement solutions that enhance productivity, assure quality and limit human interference. The range of products that comes under the sensores de proximidad fotoeléctricos segment of OMCH offers quality and variable products as per different requirements of the modern industries. With the development of automation technology, in the future, relying on a strong technical sensor market like OMCH to provide reliable, precise sensors will remain a key driving factor for a company in a globally automated environment to achieve sustainable success.