The Importance of Safety in Underwater Welding for Sustainable Development

underwater welding death rate These challenges have contributed to a high underwater welding death rate, highlighting the need to implement stricter and more efficient safety measures.”

Inspenet welding reflects the dedication of the energy sector in promoting responsible practices that benefit both people and the planet.

The Importance of Safety in Underwater Welding for Sustainable Development

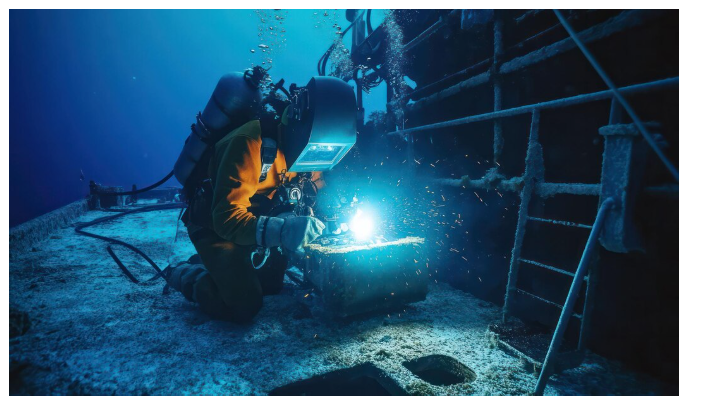

Underwater welding is an essential profession for the construction and maintenance of maritime infrastructures, such as oil platforms, pipelines, and vessels. However, it is also one of the most dangerous activities due to the extreme conditions in which it is performed. Ensuring the safety of underwater welders is not only crucial to protect human lives but also fundamental to promote sustainable development in the maritime and energy sectors.

Challenges of Underwater Welding

The combination of diving to significant depths and handling welding equipment exposes workers to multiple risks. Among the main challenges are:

- Pressure and Decompression: Underwater welders must descend to depths where the pressure is much greater than at the surface. An improper ascent can lead to decompression sickness.

- Electrical Risk: Working with electrical equipment underwater increases the risk of electrocution if proper protocols are not followed.

- Limited Visibility and Currents: Underwater conditions can be unpredictable, with low visibility and strong currents that make the work difficult and increase the risk of accidents.

These challenges have contributed to a high underwater welding death rate, highlighting the need to implement stricter and more efficient safety measures.

Safety Measures for Sustainable Development

Safety in underwater welding is a key component to ensure sustainability in the sector. Some essential measures include:

- Comprehensive Training and Certification: Underwater welders must receive extensive training covering both diving skills and advanced welding techniques. International certifications ensure that professionals are qualified to face the associated risks.

- High-Quality Equipment: Using state-of-the-art equipment and tools can significantly reduce risks. This includes specialized diving suits, communication systems, and welding equipment designed for underwater environments.

- Strict Safety Protocols: Companies must establish and enforce protocols that cover all stages of the work, from planning to execution and return to the surface. This also involves having support teams on the surface prepared to act in case of emergencies.

- Monitoring Environmental Conditions: Before and during operations, it is vital to assess water conditions, such as temperature, visibility, and the presence of currents, to adjust procedures as necessary.

Safety in Underwater Welding: Key to a Sustainable Energy Future

Safety in underwater welding is a fundamental pillar for the sustainable advancement of the maritime and energy sectors. By addressing the associated risks and establishing effective preventive measures, workers are protected, operational efficiency is improved, and the preservation of the marine environment is promoted.

It is imperative that the industry continues to innovate and adopt best practices to ensure that this essential profession can be performed safely. Collaboration among companies, international organizations, and governments is key to achieving higher safety standards.

The commitment to safety and sustainable development in underwater welding reflects the dedication of the energy sector in promoting responsible practices that benefit both people and the planet.