A Complete Guide to Linear Motion Potentiometers

Linear motion potentiometers, commonly known as linear potentiometers, are essential components in various applications where precise linear displacement measurements are required. These devices are integral in industrial and consumer electronics, providing reliable and accurate feedback for control systems. This article delves into the mechanics, applications, and benefits of linear motion potentiometers, helping you understand why these devices are vital in modern technology.

What is a Linear Motion Potentiometer?

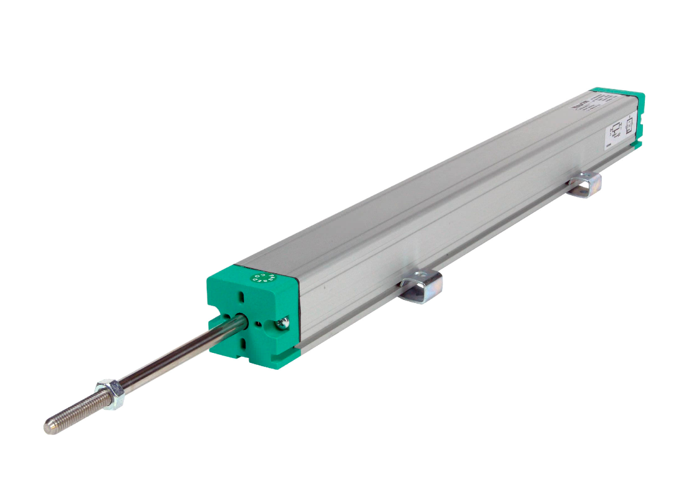

A linear motion potentiometer is a type of position sensor that converts an object’s linear displacement into an electrical signal. This signal can be measured and interpreted to determine the object’s exact position. Unlike rotary potentiometers, which measure angular displacement, linear potentiometers are designed to track straight-line movements.

How Do Linear Motion Potentiometers Work?

Linear potentiometers operate on the principle of variable resistance. The device consists of a resistive element and a movable contact known as a wiper. As the object moves along the potentiometer, the wiper slides over the resistive element, changing the resistance value. This change in resistance is directly proportional to the object’s displacement, allowing for precise position measurement.

Key Components:

- Resistive Element: The core component that provides varying resistance based on the position of the wiper.

- Wiper: The movable contact that slides along the resistive element to measure displacement.

- Housing: The outer casing that protects the internal components and provides a mounting point for the potentiometer.

Applications of Linear Motion Potentiometers

Linear motion potentiometers are widely used across industries due to their versatility and accuracy. Here are some common applications:

- Industrial Automation

In industrial settings, linear potentiometers are employed in machinery to monitor and control the position of moving parts. They ensure that components are accurately positioned for cutting, welding, and assembly processes.

- Robotics

Robotics heavily relies on precise movement control, and linear potentiometers are crucial. They provide feedback to robotic arms and actuators, enabling them to perform highly precise tasks.

- Automotive Industry

In the automotive industry, linear potentiometers are used in various systems, including throttle position sensors and suspension systems. They help monitor and adjust the position of different components to enhance vehicle performance and safety.

- Consumer Electronics

Linear potentiometers are also found in consumer electronics, such as audio equipment. They are used in volume controls and equalizers, allowing users to adjust settings precisely.

Advantages of Linear Motion Potentiometers

- High Accuracy

One of the primary advantages of linear motion potentiometers is their high accuracy. They provide precise position measurements, crucial in applications where even slight deviations can lead to significant errors.

- Durability

Modern linear potentiometers are designed to withstand harsh environments. They are built with robust materials that resist wear and tear, ensuring long-term reliability and performance.

- Cost-Effective

Compared to other position-sensing technologies, linear potentiometers are relatively cost-effective. They offer a good balance between performance and price, making them popular for various applications.

- Easy Integration

Linear potentiometers can be easily integrated into existing systems. Their straightforward design and operation make them compatible with different control systems and interfaces.

Selecting the Right Linear Motion Potentiometer

When choosing a linear motion potentiometer, several factors need to be considered to ensure optimal performance:

- Range of Motion

The range of motion is critical in determining how much displacement the potentiometer can measure. Selecting a potentiometer with a range that matches the application’s requirements is essential.

- Resolution

Resolution refers to the smallest change in position that the potentiometer can detect. Higher-resolution potentiometers provide more precise measurements, which is vital in applications requiring fine control.

- Environmental Conditions

The operating environment plays a significant role in the potentiometer’s performance. Factors such as temperature, humidity, and exposure to dust and chemicals should be considered when selecting a potentiometer.

- Mounting and Installation

Another important consideration is the ease of mounting and installation. The potentiometer should be compatible with the existing setup and easy to install without requiring significant modifications.

Conclusion

Linear motion potentiometers are indispensable in various industries, offering accurate and reliable position measurements for multiple applications. These devices ensure precise control and feedback, whether in industrial automation, robotics, automotive systems, or consumer electronics. Brands like ETI Systems and Digikey provide high-quality linear potentiometers, catering to diverse needs and ensuring top-notch performance. By understanding their mechanics and applications, you can make informed decisions when selecting the right linear potentiometer for your requirements.