Essential Factors to Consider When Choosing CNC Machining Services

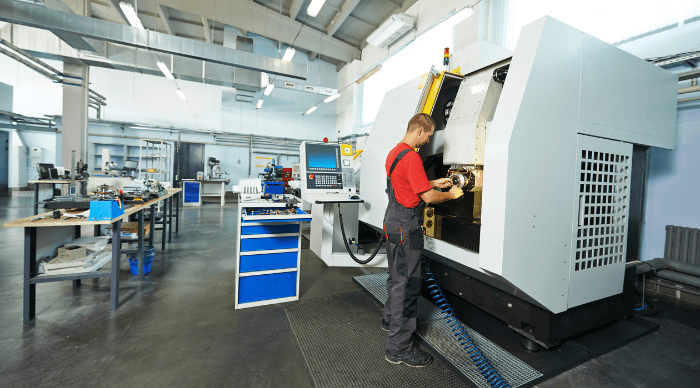

Choosing the right CNC machining services can significantly impact your project’s success and your business’s overall efficiency. Whether you’re crafting intricate components for aerospace or producing high-precision parts for medical devices, the quality and reliability of your CNC machining provider play a crucial role. With numerous providers available, making an informed decision can seem overwhelming. In this blog, we’ll explore the essential factors you need to consider to ensure you partner with a CNC machining service that meets your needs and helps you achieve your goals. From expertise and technological capabilities to turnaround time and customer service, we’ll cover all the key aspects to guide you in making the best choice.

Understanding CNC Machining Services

CNC (Computer Numerical Control) machining is a process where pre-programmed computer software controls the movement of factory tools and machinery. Key components include:

CNC Machine: Includes mills, lathes, routers, etc.

Control Panel: Interface for inputting design specifications.

Cutting Tools: Made from materials like high-speed steel or carbide.

Software: CAD and CAM software create and convert design files into machine instructions.

Common Applications Across Various Industries:

CNC machining is vital in many industries for its precision and efficiency:

Automotive: Engine components, gears, and high-volume parts.

Aerospace: Turbine blades, structural components, and landing gear.

Medical Devices: Surgical instruments, implants, and custom parts.

Electronics: Housings, heat sinks, and connectors.

Industrial Machinery: Durable, high-performance machinery parts.

Consumer Goods: Household items, sports equipment, and customized products.

Key Factors to Consider

Expertise and Experience

Choosing a CNC machining provider with skilled technicians is crucial for ensuring high-quality results. Experienced technicians possess the knowledge and precision needed to handle complex projects, troubleshoot issues, and maintain optimal machine performance. Evaluating a provider’s track record and industry experience involves looking at their portfolio of past projects, client testimonials, and the longevity of their operations. A provider with a solid history in the industry is likely to have refined their processes and built a reputation for reliability and excellence.

Range of Services Offered

A comprehensive range of CNC machining services indicates a provider’s versatility and capability to meet diverse project requirements. Key services include milling, which involves removing material to create shapes; turning, where the workpiece rotates to produce cylindrical parts; and drilling, used for creating precise holes. Other services might include grinding, routing, and EDM (electrical discharge machining). A provider offering a broad service portfolio can handle different aspects of a project, ensuring consistency and quality across all stages of production.

Quality Assurance and Certifications

Quality control measures are essential in CNC machining to ensure that the final products meet specified standards and tolerances. Providers should implement rigorous inspection processes, such as dimensional checks and surface finish assessments. Relevant industry certifications, like ISO 9001 for quality management systems and AS9100 for aerospace quality standards, indicate a provider’s commitment to maintaining high-quality practices. These certifications reassure clients that the provider adheres to internationally recognized standards, reducing the risk of defects and ensuring reliable performance.

Material Capabilities

The types of materials a CNC machining provider can handle significantly impact the suitability of their services for specific projects. Common materials include metals like aluminum, steel, and titanium; plastics such as ABS and polycarbonate; and composites. Each material has unique properties and machining requirements. Matching the provider’s material capabilities with your project needs ensures optimal performance, durability, and functionality of the final product.

Cost and Value for Money

Understanding the pricing structure of CNC machining services is essential to balance cost with quality and service level. While it’s important to find competitive pricing, the cheapest option may not always offer the best value. Consider factors like the provider’s expertise, service range, quality assurance, and technological capabilities. Investing in a reputable provider ensures that you receive high-quality parts and reliable service, ultimately offering better value for money.

Conclusion

Choosing the right CNC machining service provider is crucial for the success of your projects. Key considerations include expertise, service range, quality assurance, technological capabilities, material handling, turnaround time, and cost-effectiveness. Skilled technicians and a proven track record ensure reliable performance and high-quality results. A diverse service portfolio and advanced technology support versatility and precision in manufacturing. Quality control measures and industry certifications guarantee adherence to standards. Evaluating material capabilities and flexibility in handling custom orders ensures projects are completed on schedule. Balancing cost with value ensures optimal investment. By focusing on these factors, you can select a CNC machining partner that meets your needs and supports your business goals effectively.