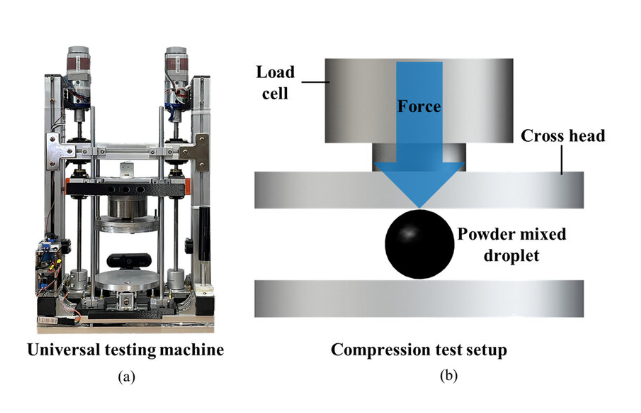

Exploring Dynamic Testing with Universal Testing Machines

Dynamic testing with Universal Testing Machines (UTMs) is a process in many industries, offering crucial insights into material behavior under varying loading conditions. From assessing automotive components’ durability to evaluating construction materials’ resilience, dynamic testing is fundamental. This article delves into the complexities of dynamic testing with UTMs. It explores its diverse applications and highlights the importance of reliable equipment for accurate and consistent results.

As industries strive for innovation and safety, understanding the nuances of dynamic testing and investing in quality UTMs from reputable manufacturers has become imperative for driving progress and maintaining competitiveness in today’s fast-paced marketplace.

Understanding Dynamic Testing

Dynamic testing is a key component of material science and engineering, providing invaluable insights into how materials behave under dynamic loading conditions. Unlike static testing, which applies a constant load, dynamic testing involves subjecting materials or structures to varying loads and speeds to replicate real-world conditions. This methodology enables engineers to assess how materials respond to dynamic forces such as vibrations, impacts, or cyclic stresses, which are prevalent in operational environments.

One of the primary advantages of dynamic testing is its ability to analyze dynamic properties crucial to product performance and safety. For instance, engineers can evaluate fatigue, a phenomenon where materials weaken over time due to repeated loading and unloading cycles. By subjecting materials to controlled dynamic loading conditions, engineers can simulate the wear and tear experienced during the product’s lifecycle, allowing them to predict and mitigate potential failure modes.

Another key aspect of dynamic testing is the assessment of fracture toughness, which refers to a material’s ability to withstand crack propagation under dynamic loading. Understanding fracture toughness is necessary for designing resilient structures and components, particularly in industries where safety is paramount.

Moreover, dynamic testing provides insights into how materials behave under impact loading, which is crucial for assessing vehicle and structure crashworthiness. By subjecting materials to controlled impact forces, engineers can evaluate their ability to absorb energy and dissipate it without catastrophic failure.

Applications in Different Industries

Dynamic testing with Universal Testing Machines is an effective tool with widespread applications within diverse industries. Automotive engineering uses dynamic testing to evaluate vehicle components’ impact resistance. For example, crash tests conducted using UTMs simulate real-world collisions, allowing engineers to assess how different materials and designs withstand impact forces. These tests provide valuable data for improving vehicle safety standards and developing crash-worthy designs that protect occupants in accidents.

In the aerospace industry, dynamic testing is crucial for ensuring aircraft components’ structural integrity under varying flight conditions. For instance, wing structures undergo dynamic testing to assess their durability and fatigue resistance under aerodynamic loads experienced during takeoff, landing, and flight maneuvers. By subjecting aircraft components to dynamic loading conditions using UTMs, engineers can identify potential weaknesses and design modifications to enhance overall safety and performance.

Furthermore, dynamic testing with UTMs plays an important role in materials research across various industries. Scientists use dynamic testing to study metals, polymers, and composites under dynamic loading conditions. For example, researchers may investigate the fatigue properties of metal alloys used in structural applications or the impact resistance of polymer composites used in lightweight materials.

By understanding how materials respond to dynamic forces, researchers can develop advanced materials with improved performance characteristics, such as enhanced strength, durability, and impact resistance.

Moreover, dynamic testing enables industries to comply with regulatory standards and quality assurance requirements. For example, consumer goods manufacturers, such as electronics and sporting equipment, use dynamic testing to ensure product safety and reliability.

By subjecting products to dynamic loading conditions similar to those encountered during normal use, manufacturers can identify potential design flaws or manufacturing defects early in the development process, reducing the risk of product failures and recalls.

Importance of Reliable Equipment and Manufacturers

Dynamic testing requires reliable equipment and manufacturers. Investing in high-quality Universal Testing Machines is crucial to guarantee accurate and repeatable test results. Quality UTMs are engineered to withstand rigorous testing conditions, offering robust performance and reliability over extended periods of use.

One of the key features of quality UTMs is their ability to provide precise control over load rates, frequencies, and displacements during dynamic testing. This level of control is essential for accurately simulating real-world loading conditions and obtaining reliable data on material behavior under dynamic forces whether testing automotive components’ impact resistance or evaluating structural materials’ fatigue properties, precise control over testing parameters is crucial for meaningful results.

Moreover, reputable UTM manufacturers offer customizable solutions designed to meet specific testing requirements. This customization capability means that UTMs are compatible with different specimen geometries, sizes, and materials, allowing for versatile testing applications across different industries. Whether testing small-scale specimens in a laboratory setting or conducting large-scale structural tests in industrial environments, UTMs can be tailored to suit the needs of each application.

Furthermore, reputable manufacturers provide comprehensive support services, including installation, training, and ongoing maintenance. Proper installation and training are essential for ensuring UTM optimal performance and maximizing its effectiveness in dynamic testing applications. Additionally, regular maintenance and calibration services help ensure test results’ accuracy and reliability over time, minimizing the risk of equipment malfunctions or inaccuracies.

Choosing a reliable UTM manufacturer is essential to maintaining dynamic testing equipment quality and performance. Reputable manufacturers comply with strict quality control standards and employ advanced engineering techniques to produce UTMs that meet the highest industry standards. By investing in UTMs from trusted manufacturers, industries can trust the accuracy, reliability, and longevity of their testing equipment.