From Paper HACCP to Digital Oversight: Faster Audits, Fewer Deviations

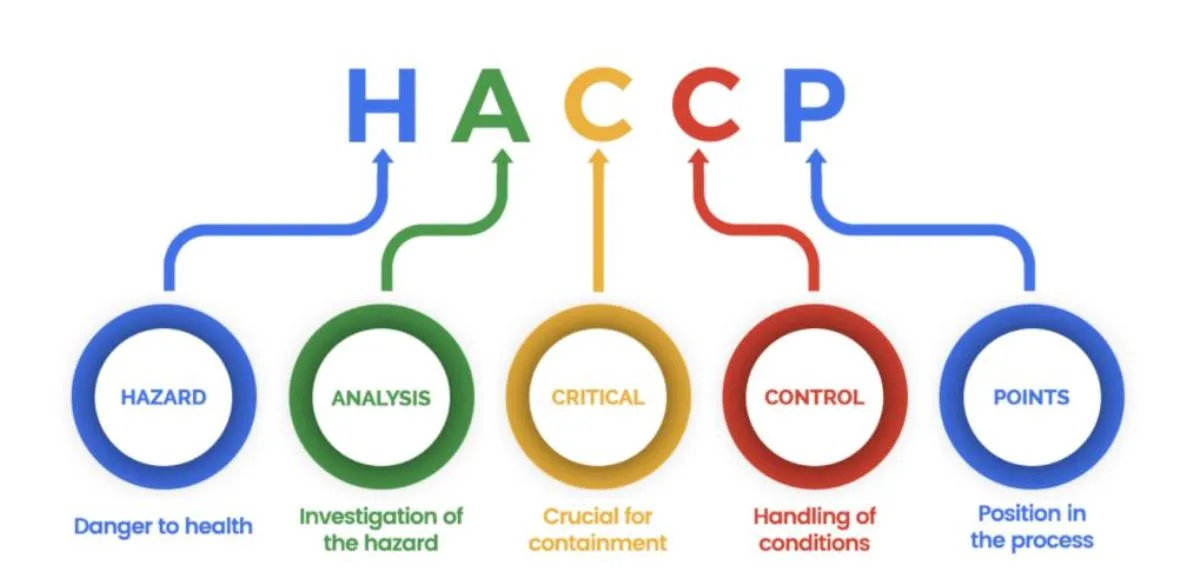

Hazard Analysis and Critical Control Points (HACCP) has been the cornerstone of food safety management for decades. Traditionally, HACCP plans have been documented and monitored through paper logs, clipboards, and manual checklists. While this method worked in the past, it no longer meets the speed and precision required in today’s food industry. With regulations such as FSMA tightening oversight, relying on outdated tools has become a liability.

The shift to digital oversight through HACCP software and integrated food safety software is no longer optional. Companies that continue to depend on paper-based systems risk slower audits, higher rates of non-conformance, and increased recall exposure. In contrast, businesses that adopt digital tools see faster audits, fewer deviations, and stronger compliance across their operations.

This article explores how moving from paper HACCP to digital oversight can transform compliance and efficiency, especially for frozen food operations, and how systems such as Frozen Foods ERP play a critical role in creating a resilient and transparent food safety culture.

The Limitations of Paper HACCP Systems

Paper-based HACCP records present several challenges that weaken compliance and efficiency:

- Manual errors: Handwritten logs are prone to mistakes, incomplete fields, and inconsistent data entry.

- Storage and retrieval problems: Large binders of records are difficult to store, organize, and retrieve quickly during an audit.

- Limited traceability: When deviations occur, identifying root causes or affected batches can take days rather than hours.

- Lack of integration: Paper systems cannot connect with temperature sensors, inventory tools, or production data, leaving critical blind spots.

- Audit delays: During inspections, auditors often spend valuable time flipping through pages instead of reviewing digital, real-time reports.

These weaknesses become even more problematic under FSMA compliance requirements, where regulators expect faster and more transparent access to accurate data.

Why Digital Oversight is the Future of HACCP

Digital oversight replaces binders of paper records with centralized HACCP software that captures, organizes, and analyzes data in real time. By digitizing HACCP plans and integrating them into broader food safety software, food companies can transform compliance from a reactive burden into a proactive advantage.

Core Benefits of Digital HACCP Oversight

- Real-time monitoring: Critical Control Points (CCPs) such as cooking, cooling, or freezing temperatures are tracked continuously with automated alerts for deviations.

- Data accuracy: Digital forms reduce human error, enforce required fields, and standardize entries.

- Audit readiness: Auditors can access reports in minutes instead of sifting through stacks of paper.

- Traceability: Linking HACCP data with lot tracking and supply chain events strengthens root cause analysis.

- Scalability: Multi-site operations can standardize HACCP compliance across facilities without duplicating effort.

The move to digital oversight is not just about replacing paper. It creates a system of record that is integrated, actionable, and aligned with FSMA’s vision of preventive controls.

FSMA Compliance and Digital HACCP

The Food Safety Modernization Act (FSMA) is one of the driving forces behind the digital transition. FSMA emphasizes prevention, accountability, and speed in addressing food safety risks. Under FSMA, businesses must not only document their HACCP plans but also prove that controls are working effectively.

How HACCP software supports FSMA compliance:

- Documented preventive controls: Every step in the HACCP plan is digitally recorded, time-stamped, and linked to responsible staff.

- Verification and validation: Automated workflows verify that checks are completed on time and flag any missed records.

- Faster recall response: Linking HACCP records with lot numbers allows for rapid identification of affected products.

- Regulatory reporting: Digital oversight makes it easier to provide standardized data to inspectors within the required timeframes.

For frozen food companies, FSMA 204 traceability rules are especially relevant. Digital HACCP oversight ensures that critical data points such as temperature monitoring and storage records are captured seamlessly, helping organizations stay compliant without slowing operations.

Faster Audits, Fewer Deviations

The most visible benefit of digital HACCP oversight is improved audit performance.

- Audit preparation: Instead of spending days gathering paper records, companies can generate audit reports with a single click.

- Reduced deviations: Automated alerts prevent small issues from becoming major violations.

- Data transparency: Auditors gain confidence in standardized, time-stamped records that cannot be altered retroactively.

- Regulatory trust: Demonstrating a proactive approach to safety reduces the risk of penalties and strengthens relationships with regulators.

Companies that make the switch often report that audits are smoother, shorter, and less stressful. This allows quality teams to spend more time improving processes and less time managing paperwork.

Building a Culture of Digital Food Safety

Technology alone cannot guarantee compliance. For digital HACCP oversight to succeed, companies must also build a culture that values accuracy, accountability, and continuous improvement.

Steps to build a strong culture:

- Staff training: Teach employees why digital oversight matters and how to use HACCP software effectively.

- Internal audits: Run regular digital audits to identify weaknesses before regulators do.

- Supplier alignment: Require key suppliers to adopt compatible digital systems or provide verifiable data.

- Continuous review: Treat HACCP oversight as a living system that evolves with operations and regulatory changes.

With a strong food safety culture supported by technology, compliance becomes sustainable rather than a burden.

Business ROI of Digital HACCP Oversight

The shift to digital oversight often delivers measurable returns beyond compliance:

- Reduced waste: Improved monitoring minimizes product loss due to spoilage or temperature abuse.

- Lower recall costs: Faster root cause analysis reduces the scope and expense of recalls.

- Operational efficiency: Staff spend less time on paperwork and more time on process improvements.

- Customer trust: Retailers and consumers prefer brands that demonstrate transparency and safety.

In short, digital HACCP oversight pays for itself through efficiency gains, risk reduction, and stronger market reputation.

Conclusion:

Moving from paper HACCP to digital oversight is no longer just an efficiency choice. It is a necessity for meeting FSMA requirements, surviving audits, and maintaining consumer trust. HACCP software and food safety software provide the tools needed to achieve faster audits and fewer deviations.

Folio3 FoodTech delivers solutions tailored to the unique needs of the food industry. From digital HACCP oversight to integrated ERP systems, Folio3 FoodTech helps businesses achieve full FSMA compliance while also improving efficiency and profitability. If your organization is ready to replace paper binders with a smarter, digital system, Folio3 FoodTech is ready to support that transformation.