How A Bending Calculator Can Improve Manufacturing Efficiency

There can be a number of reasons why efficiency can be affected in manufacturing. One of the biggest issues is errors in calculation. Manufacturing often involves accurate calculations of various measures.

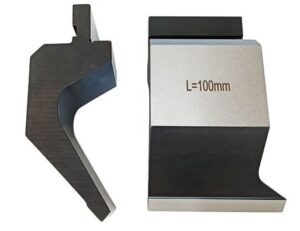

In the case of press brake tooling, it can be the calculation of the bend radius, bend deduction, and bend allowance. These types of calculations help in creating a perfect product in the end. So, in this article, we will try to look at how a bending calculator can improve manufacturing efficiency.

The role of precision in manufacturing

A Sheet Metal Bending Calculator plays an important role in the manufacturing process. It helps in removing the errors in the product as well as helps in avoiding waste creation. Also, it helps in meeting the strict standards of various fields like aerospace and automobile. So, in the end, Sheet Metal Building Calculator helps in optimizing the entire process.

Benefits of using a bending calculator

Sheet Metal Bending Calculator often helps in several ways. One of the prominent advantages is accurate bending calculations. These involve numerous attributes. Some of them are material type and material thickness. This type of regulation can become complex if done manually. So, it is preferable to use a sheet metal bending calculator to automate the process. In the end, we will be able to get an accurate result and also save our energy.

• Time-saving

Any automatic process can often help in saving time. It is also the case for sheet metal bending calculators. As a result, engineers and fabricators will be able to put their focus on another task to increase productivity.

In the case of manufacturing, precision generally plays an important role. So, by precisely calculating different measures, time can be saved for improving the output. So, sheet metal bending also becomes a time saver for us in some cases.

• Reduce material waste

Another advantage of sheet metal bending calculation is reducing the wastage of material. It is because inaccurate calculations can often result in scrapping products and raw materials that are being used in the production of wrong products. So, it is important to make the accurate calculations. It will help in avoiding wastage in the end.

• Consistency in production

Apart from all of the above points, consistency also presents an important role in production. So, accurate calculations can often help in making a product at a rapid and consistent pace. So, consistency is maintained in production, to maintain the tight standards of quality check.

• Optimized workflow

Sheet metal bending is done by Press Brake Tooling. So a Press Brake Tooling Manufacturer often needs optimized workflow. So, the sheet metal bending calculator helps in optimizing the entire production process. This involves saving time and energy in manual calculation, to focus on other important aspects of the production.

So, these are some of the points, that help in developing the significance of sheet metal building calculation in the real world. It often improves this standard to enhance both productivity and cost-effectiveness in the fabrication industry. To learn more, you can click on the link.