How GR Prototypes Deliver Precision and Innovation in Rapid Prototyping

In today’s fast-paced manufacturing world, companies constantly seek ways to reduce time-to-market, optimize product development cycles, and ensure that every component meets precise specifications. This is where rapid prototyping has become a game-changer, allowing manufacturers to test and iterate designs with incredible speed and accuracy. At the forefront of this revolution is GR Prototypes, a leader in delivering cutting-edge rapid prototype solutions that blend innovation with precision. From CNC machining to advanced rapid prototyping techniques for chassis creation, GR Prototypes is revolutionizing how products are brought to life.

The Role of Rapid Prototyping in Modern Manufacturing

Rapid prototyping is an essential tool in product development. It allows designers and engineers to quickly create functional models or prototypes that can be evaluated, tested, and refined before full-scale production. The importance of this process lies in its ability to accelerate innovation, reduce development costs, and ensure that potential design flaws are caught early.

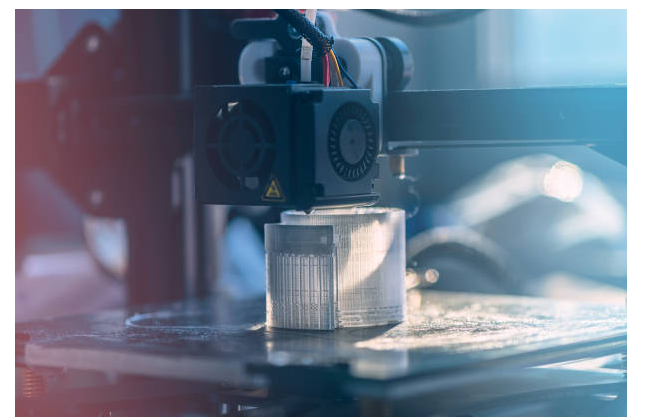

Traditional manufacturing techniques often involve long lead times and are costly for producing prototypes, especially when multiple iterations are needed. However, rapid prototyping leverages modern technologies such as 3D printing, CNC machining, and additive manufacturing to produce highly accurate prototypes in a fraction of the time and cost.

For industries like automotive, aerospace, and consumer electronics, where innovation and precision are crucial, rapid prototyping has become an indispensable part of the development process. GR Prototypes takes this to the next level by offering a comprehensive suite of services tailored to meet the unique needs of each client.

Precision with CNC Machining: A Cornerstone of GR Prototypes

One of the standout services offered by GR Prototypes is CNC machining. CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized controls to operate machinery and tools to shape metal, plastic, and other materials into precise designs.

What sets CNC machining apart from other techniques is its ability to achieve extreme precision and repeatability, even with complex geometries. For industries that require tight tolerances, such as automotive or aerospace, CNC machining is an ideal solution. GR Prototypes has invested in state-of-the-art CNC machining equipment, allowing them to produce components with exceptional accuracy.

GR Prototypes leverages CNC machining not just for prototyping but also for low-volume production runs. This means that clients can move seamlessly from prototype to production, ensuring that the final product retains the same level of precision and quality. Whether it’s for chassis creation, mechanical components, or intricate parts, GR Prototypes’ CNC machining capabilities provide unmatched flexibility and reliability.

Rapid Prototyping Techniques for Chassis Creation

Chassis creation, particularly for industries like automotive and aerospace, demands a unique combination of strength, lightweight materials, and precise design. GR Prototypes is at the cutting edge of rapid prototyping techniques for chassis creation, offering solutions that cater to the demands of modern engineering.

The traditional process of designing and manufacturing a chassis can be time-consuming and costly. However, rapid prototyping dramatically shortens the time needed for developing chassis designs. By utilizing both subtractive and additive manufacturing techniques, GR Prototypes can produce chassis components quickly, allowing engineers to test structural integrity, weight distribution, and other critical factors early in the development cycle.

For instance, 3D printing is used to create complex geometric shapes that would be difficult or impossible to achieve with traditional methods. By combining this with CNC machining, GR Prototypes ensures that every part of the chassis is built to the exact specifications needed, balancing form and function perfectly.

This approach has a profound impact on the overall product development process. Engineers can make real-time adjustments to the chassis design based on testing feedback, iterating quickly and efficiently. Whether it’s for a concept car, drone, or high-performance vehicle, GR Prototypes’ advanced techniques in chassis creation provide manufacturers with the tools to innovate faster than ever before.

Innovation in Rapid Prototyping: From Concept to Production

Innovation is at the heart of everything GR Prototypes does. By continuously investing in the latest technologies and refining their processes, they can offer clients cutting-edge solutions that are both scalable and customizable.

For companies in industries like consumer electronics, where product lifecycles are short and the pressure to innovate is high, rapid prototyping is essential. GR Prototypes offers a variety of prototyping techniques to suit different stages of the product development process. Whether a company needs early-stage concept models or fully functional prototypes ready for user testing, GR Prototypes has the expertise and equipment to deliver.

One of the key advantages of working with GR Prototypes is the ability to scale production as needed. This means that a prototype can easily transition into a small production run without losing any of the accuracy or quality achieved during the initial stages. By offering services such as CNC machining and 3D printing under one roof, GR Prototypes ensures that the entire product development process is streamlined and efficient.

Customization and Flexibility: A Client-Centered Approach

Every product development project is unique, and GR Prototypes understands that a one-size-fits-all approach won’t work. That’s why they offer a high degree of customization and flexibility in their services. From material selection to finishing options, clients can tailor their prototypes to meet specific functional, aesthetic, or regulatory requirements.

For example, in the aerospace industry, materials must meet stringent safety and performance standards. GR Prototypes’ team of experts works closely with clients to ensure that the materials used in the prototyping process meet these standards while maintaining the design’s integrity. Likewise, automotive manufacturers rely on GR Prototypes to deliver durable, lightweight prototypes that can withstand rigorous testing.

This client-centered approach extends beyond technical expertise. GR Prototypes prides itself on building long-term relationships with clients, providing ongoing support and guidance throughout the development process. Whether it’s troubleshooting a design issue or advising on the best manufacturing techniques for a particular project, GR Prototypes is committed to delivering value at every stage.

The Future of Rapid Prototyping with GR Prototypes

As industries continue to evolve, the demand for faster, more efficient product development processes will only grow. GR Prototypes is poised to lead the way, continuously expanding its capabilities and staying ahead of the curve in rapid prototype innovation.

Their commitment to precision, quality, and innovation has already set them apart as a trusted partner for manufacturers worldwide. With expertise in CNC machining, rapid prototyping techniques for chassis creation, and a wide range of other services, GR Prototypes is helping companies revolutionize the way products are designed and developed.

In the future, we can expect GR Prototypes to continue pushing the boundaries of what’s possible with rapid prototyping, providing companies with the tools they need to innovate, iterate, and succeed in an increasingly competitive global market.

With rapid prototyping and CNC machining expertise, GR Prototypes is not only transforming how prototypes are created but also how industries innovate. Whether it’s chassis creation or cutting-edge electronic components, GR Prototypes remains a leader in precision and innovation.