How Motor Winding Machines are Revolutionizing the Manufacturing Industry.

Introduction.

In the realm of modern manufacturing, precision and efficiency are paramount. To meet the demands of various industries, the motor coil winding machine has emerged as a game-changer. This article explores the functionalities, benefits, and applications of motor coil winding machines, shedding light on their crucial role in the manufacturing process.

What is Motor Coil Winding?

Motor coil winding refers to the process of creating wire coils that are integral components in various electrical and electronic devices. These coils serve as electromagnetic conductors, generating the necessary magnetic fields for proper device functionality. Motor coil winding machines automate this process, ensuring consistent and precise winding of wire onto bobbins or other core structures.

The Importance of Motor Coil Winding Machines.

Motor coil winding machines have revolutionized the manufacturing industry by significantly enhancing the efficiency and accuracy of the coil winding process. Traditional manual winding methods are time-consuming and prone to human error, resulting in variations in coil quality. With motor winding machines, manufacturers can achieve higher production volumes, improved quality control, and reduced labor costs.

How Motor Coil Winding Machines Work.

Basic Components.

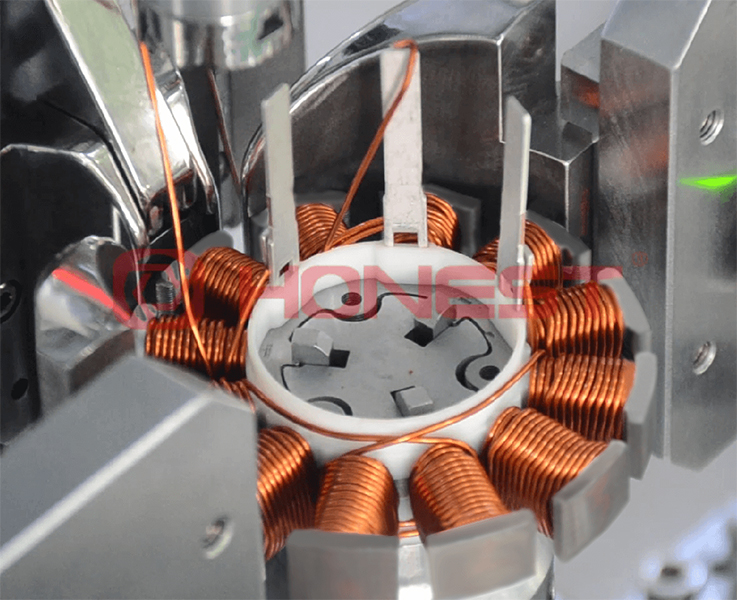

Motor coil winding machines consist of several key components, including a wire dispenser, a tensioning system, a winding spindle, and a control system. The wire dispenser feeds the wire onto the winding spindle, which rotates and guides the wire onto the coil-forming structure. The tensioning system ensures consistent tension throughout the winding process, preventing wire breakage or slack.

Winding Techniques.

Motor coil winding machines employ various winding techniques based on the desired coil specifications. These techniques include random winding, layer winding, and precision winding. Random winding is suitable for simple coils, layer winding provides improved precision for complex coils, and precision winding achieves the highest level of accuracy for intricate coil designs.

Automation and Control Systems.

Modern motor coil winding machines feature advanced automation and control systems. These systems allow for programmable parameters such as winding speed, tension control, layer thickness, and wire diameter. By inputting the desired specifications into the control system, manufacturers can achieve consistent and repeatable results, even for complex coil designs.

Benefits of Motor Coil Winding Machines.

Improved Efficiency and Productivity.

Motor coil winding machines significantly boost manufacturing efficiency by automating the labor-intensive process of coil winding. With higher production speeds and reduced human intervention, manufacturers can meet tight deadlines and increase overall productivity.

Consistency and Accuracy

Precision is crucial in coil winding, as even slight variations can affect the performance of electrical and electronic devices. Motor coil winding machines ensure consistent and accurate winding, minimizing defects and ensuring the uniform quality of each coil produced.

Cost-Effectiveness and Time-Saving.

By automating the coil winding process, manufacturers can save on labor costs and reduce time spent on manual winding. The speed and efficiency of motor coil winding machines translate into cost savings and faster time-to-market for products.

Versatility and Customization.

Motor coil winding machines offer a high degree of versatility and customization. They can accommodate a wide range of coil specifications, including different wire types, coil dimensions, and winding techniques. This flexibility allows manufacturers to cater to diverse industry requirements.

Applications of Motor Coil Winding Machines.

Motor coil winding machines find applications across various industries, including:

Electrical and Electronics Industry.

In the electrical and electronics industry, motor coil winding machines are essential for the production of transformers, electric motors, generators, and inductors. These components are integral to numerous devices, from household appliances to industrial machinery.

Automotive Industry.

Motor coil winding machines play a vital role in the production of automotive components such as ignition coils, solenoids, and electric vehicle motors. These components are critical for the efficient operation of vehicles and the transition to electric mobility.

Renewable Energy Sector.

With the growing demand for renewable energy sources, motor coil winding machines are instrumental in the production of wind turbines, solar panels, and energy storage systems. These machines enable the efficient generation and utilization of renewable energy.

Industrial Automation and Robotics.

Motor coil winding machines contribute to the manufacturing of automation and robotics components, including servo motors, stepper motors, and actuators. These components drive the precision and reliability of automated systems across industries.

Factors to Consider when Choosing a Motor Coil Winding Machine.

When selecting a motor coil winding machine, manufacturers should consider the following factors:

Coil Specifications.

The machine should be capable of accommodating the desired coil specifications, including wire type, diameter, insulation, and dimensions. Compatibility with the required winding techniques is also crucial.

Production Volume and Speed.

Manufacturers should assess their production volume requirements and choose a machine that can meet the desired speed and output. High-speed machines are suitable for large-scale production, while slower machines may be more appropriate for smaller volumes.

Automation and Integration Capabilities.

Integration with other manufacturing processes and automation systems is essential for seamless production workflows. Manufacturers should opt for machines that offer compatibility with industry-standard control systems and data exchange protocols.

Reliability and Maintenance.

Reliability is vital to ensure uninterrupted production and minimize downtime. Additionally, manufacturers should consider the ease of maintenance and availability of spare parts when selecting a motor coil winding machine.

Emerging Trends in Motor Coil Winding Technology.

As technology continues to advance, motor coil winding machines are also evolving. Some emerging trends in motor coil winding technology include:

Smart Winding Machines.

Smart winding machines incorporate advanced sensors, machine learning algorithms, and real-time data analysis to optimize the winding process. These machines can detect anomalies, adjust winding parameters, and provide insights for predictive maintenance.

Integration with Industry 4.0 Technologies.

Motor coil winding machines are increasingly integrated into Industry 4.0 frameworks, enabling connectivity, data exchange, and remote monitoring. This integration enhances process control, quality assurance, and overall operational efficiency.

Advanced Materials and Designs.

Motor coil winding machines are adapting to accommodate new materials and design requirements. This includes the use of advanced conductive materials, multi-layered coils, and intricate geometries for improved performance and miniaturization.

FAQs.

Q: What is the purpose of motor coil winding?

The purpose of motor coil winding is to create wire coils that generate the necessary magnetic fields in electrical and electronic devices, enabling their proper functionality.

Q: Can motor coil winding machines handle different types of coils?

Yes, motor coil winding machines can handle various types of coils, including those with different wire types, dimensions, and winding techniques. They offer flexibility and customization options.

Q: How do motor coil winding machines ensure precision and accuracy?

Motor coil winding machines employ automation and control systems to ensure precise control over winding parameters, such as speed, tension, and layer thickness. This automation eliminates human errors and inconsistencies.

Q: Are motor coil winding machines suitable for small-scale production?

Yes, motor coil winding machines can be used for both small-scale and large-scale production. Their flexibility allows manufacturers to adjust the production volume and meet specific requirements.

Q: What are the maintenance requirements for motor coil winding machines?

Maintenance requirements for motor coil winding machines typically include regular cleaning, lubrication, and inspection of components. It is also important to follow manufacturer guidelines and schedule preventive maintenance to ensure optimal performance.

Conclusion.

Motor coil winding machines have revolutionized the manufacturing industry by streamlining the production of critical electrical and electronic components. With their precision, efficiency, and versatility, these machines enable manufacturers to meet the demands of diverse industries while ensuring consistent quality and reduced costs. As technology continues to advance, motor coil winding machines will play an even more pivotal role in shaping the future of manufacturing.