How to Fix Elephant Foot Problem in 3D Prints

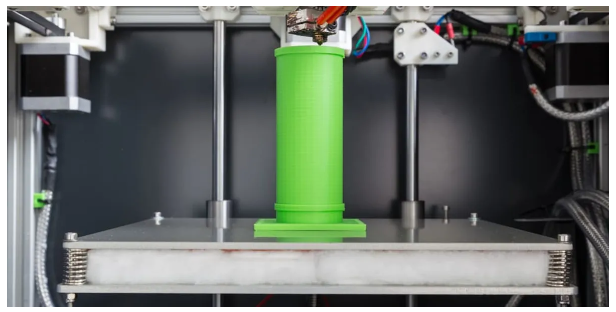

Are you frustrated with the elephant foot problem ruining your 3D prints? Don’t worry; you’re not alone! The elephant foot issue occurs when the bottom layers of your print spread out, leading to an uneven base and compromising your design’s accuracy. But fear not! There are effective solutions to tackle this common setback and achieve smoother, more precise prints. By understanding the causes and implementing simple adjustments in your printing process, you can bid farewell to the pesky elephant foot phenomenon. Let’s explore practical techniques to fix this problem and effortlessly elevate your 3D prints’ quality.

What is the Elephant Foot phenomenon?

In 3D printing, there’s the “elephant foot.” It happens when the bottom of a printed object bulges out, looking like an elephant’s foot. This bulge can be tiny, just a few microns, or bigger, stretching a few millimeters past what’s supposed to be there.

The elephant foot happens because of how 3D printing works. When each layer of material is laid down, it gets heated and then cools quickly to become solid. The first layers, which are closest to the hot print bed, stay warm longer. They stay soft while the other layers pile on top. This softness, plus the weight of the added layers, makes the bottom layers spread out, creating that elephant foot shape.

So, it’s all about the physics of the printing process. The way heat moves and materials cool affects how the layers stick together and shape the final product. That’s why understanding the elephant foot phenomenon helps in making better 3D prints without those unexpected bulges at the bottom.

Reasons for Elephant Foot in 3D Printing

When it comes to understanding the causes behind the occurrence of elephant feet in 3D printing, it’s essential to delve into various factors that contribute to this phenomenon. Elephant foot, a term used to describe the bulging or spreading of the base layers of a printed object, can result from several key factors inherent in the 3D printing process.

Temperature Dynamics

A primary factor contributing to elephant foot lies in the delicate balance of temperature control within the 3D printing environment. Specifically, the elevated temperature of the print bed plays a pivotal role in ensuring proper adhesion of the initial layers of the print to the build platform. Maintaining temperatures ranging from 60 to 110 °C, depending on the material, is often necessary to keep the bottom layers in a semi-melted state for an extended period. While this aids in initial adhesion, it also leaves room for the subsequent layers to exert pressure on the base layers, causing them to spread out, thus resulting in the elephant foot effect. Inadequate cooling from the printer’s fan further exacerbates this issue, allowing the softened layers to deform under the weight of subsequent layers.

Bed Leveling Challenges

Inaccuracies in bed leveling represent another significant contributor to the manifestation of elephant foot in 3D prints. The distance between the nozzle and the bed must be meticulously calibrated to ensure optimal printing conditions. However, if this distance is too small, the first layer of the print may be excessively squished onto the bed, causing the material to spread outward beyond the intended footprint. This challenge becomes more pronounced in printers with manual bed leveling systems, where human error can introduce inconsistencies in the printing process, exacerbating the risk of elephant foot.

Additional Factors at Play

Beyond temperature dynamics and bed leveling challenges, several other factors can contribute to the occurrence of elephant feet in 3D prints. Environmental factors, such as ambient temperature and airflow around the printer, can influence the cooling rate of the extruded filament, impacting the solidification of the base layers. Moreover, the design of the object being printed and the infill densities employed can also play a role. High infill densities, for instance, can generate internal stress within the part as it cools, leading to uneven shrinkage and potentially exacerbating the spread of the bottom layers.

Implications of Elephant Foot in 3D Printing

The presence of elephant feet in 3D prints carries significant implications both in terms of aesthetics and functionality, which warrant careful consideration within the realm of additive manufacturing.

Aesthetic Considerations

From an aesthetic standpoint, the outward spread at the base of a printed object disrupts the intended design, resulting in a distorted profile that deviates from the original specifications. This distortion poses particular challenges for prints intended to serve as accurate models or prototypes, where precision and fidelity to the original design are paramount. The presence of elephant feet can compromise the visual appeal and overall quality of the printed object, detracting from its intended purpose and aesthetic value.

Functional Ramifications

Beyond aesthetic concerns, the presence of elephant feet can have tangible functional ramifications, particularly in scenarios where precise dimensional accuracy is essential. In instances where 3D-printed objects are intended to fit into existing assemblies or interface with other components, the outward bulge at the base can disrupt tolerance levels, rendering the part larger than anticipated and potentially impeding proper fit and functionality. This is particularly pertinent in designs where intricate interlocking mechanisms or precise mating surfaces are integral to the overall functionality of the printed object.

Moreover, the structural integrity of the printed object may be compromised due to the heightened stress experienced by the bottom layers as a result of the spreading phenomenon. This increased stress renders the print more susceptible to cracking or failure, especially under load or impact conditions, posing durability concerns and limiting the functional lifespan of the printed component.

Addressing Elephant Foot: Troubleshooting Techniques

Given the critical implications associated with the occurrence of elephant foot in 3D printing, it becomes imperative to explore effective troubleshooting techniques aimed at mitigating or entirely resolving this issue.

Calibration Measures

Proper calibration of the 3D printer represents a fundamental step in addressing elephant feet and optimizing print quality. Bed leveling and nozzle height emerge as primary calibration parameters warranting meticulous attention to ensure optimal printing conditions.

Bed Leveling Optimization

Achieving precise alignment and levelness of the build plate is paramount to the quality of the first layer and the overall print. Calibration efforts should focus on maintaining a consistent distance between the build plate and the nozzle across multiple points, thereby minimizing variations that could contribute to the elephant foot. Additionally, adjustments to the Z-axis configuration, such as loosening eccentric nuts and screws, can alleviate mechanical constraints contributing to the phenomenon.

Design Adaptations

Incorporating design modifications, such as chamfers or sloping edges, into CAD 3D models represents a proactive measure aimed at mitigating the effects of elephant foot. Chamfers serve to offset the spread of the bottom layers, thereby minimizing distortion and promoting dimensional accuracy in the final print.

Slicer Parameter Optimization

Fine-tuning slicer settings represents another avenue for mitigating elephant feet in 3D prints. Adjustments to parameters such as bed temperature, first layer settings, and expansion compensation can exert significant influence over print quality and dimensional accuracy. By optimizing these settings, users can minimize the risk of elephant foot while preserving adhesion and structural integrity.

Post-Processing Techniques

In scenarios where elephant foot is present despite calibration and design interventions, post-processing techniques offer a viable means of remediation. Techniques such as sanding, filing, chemical smoothing, and heat treatment enable users to refine the surface finish and correct dimensional imperfections introduced by elephant foot, thereby enhancing the overall quality and functionality of the printed object.

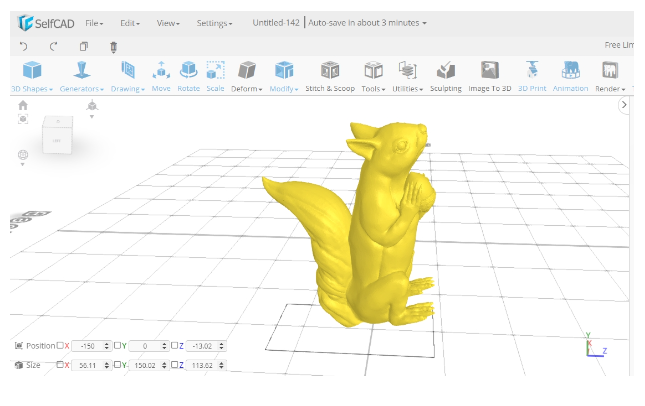

SelfCAD: Best 3D Modeling Software of 2024

SelfCAD stands out as a top choice among 3D printing software options. With its intuitive interface, it caters to users of varying skill levels. Notably, it offers versatile freehand drawing and sketching tools alongside a suite of modification options, empowering users to craft designs from the ground up. Additionally, SelfCAD boasts a rich array of 3D sculpting brushes, facilitating precise and various 3D design, modification, and deformation tools.

Furthermore, to streamline the preparation process for 3D printing, SelfCAD integrates an online slicer compatible with most common FDM 3D printers. Its cloud-based nature enables seamless accessibility across devices and locations. For added convenience, a downloadable version ensures offline usability, with both iterations remaining synchronized. This ensures that your work remains consistent and accessible whether you’re online or off, granting flexibility and reliability in the creative process. With SelfCAD, the possibilities of 3D printing and design are readily within reach.