How to optimize the pattern on the surface of custom tin cans?

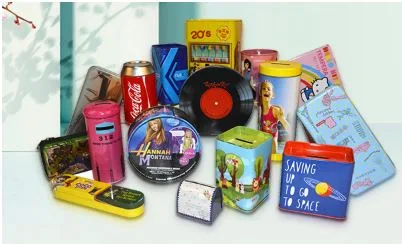

Custom tin cans do more than protect the product; they also need to attract customers at first sight. Optimizing the graphic design on the surface of the tin can enhance brand recognition, increase shelf impact, and strengthen the narrative of the brand story. Whether your custom tin is used to hold exquisite teas, handmade candies, or high-end cosmetic samples, the right graphic design can make the tin packaging a silent salesperson.

Customize Tin Cans and Brand Identity through Graphic Design

Carefully designed graphics on custom tins serve as visual shorthand for a brand’s image. Consistent use of shapes, patterns, and color schemes across a packaging series can enhance brand recognition and trust. For example, an organic tea brand may use hand-painted leaf outlines on its custom tins to highlight its natural ingredients and handmade production. Conversely, a scientific supplement label can use transparent, interlocking polygons to convey precision and innovation.

Additionally, graphic design can convey product attributes at a glance. Metallic foil patterns can suggest luxury and exclusivity, while matte tone-on-tone textures can evoke sustainability and understated elegance. Incorporating these elements into the surface design can guide consumers’ expectations before they even open the can. Graphics that align with the product story can strengthen emotional bonds, encourage repeat purchases, and foster word of mouth. However, brand identity is more than just visual; it encompasses brand heritage, core values, and market positioning.

Printing techniques for custom tin cans for optimal graphic reproduction

Choosing the right printing method is crucial to bringing complex graphics on custom tins to life. Offset printing remains the workhorse for high-volume production, offering precise color registration, fine-line reproduction, and cost efficiency at scale. However, for smaller batches or variable data graphics, digital printing provides flexibility without sacrificing print quality.

Additionally, advanced technologies such as UV-curable inks and screen printing enable the creation of special effects. UV inks adhere quickly, creating vibrant colors on curved tin surfaces, while screen printing deposits thicker layers of ink for tactile relief. Embossing or debossing combined with spot varnishing can create a dynamic contrast between matte and glossy areas, adding depth to your custom tin design.

Color and finish selection to enhance the effect of the pattern

Color selection can determine the effect of the custom tin can pattern. Bright colors can attract the eye, but they must align with brand guidelines and consumer psychology. For example, deep emerald green with metallic gold foil embodies luxury and heritage. At the same time, bright pastel tones convey a sense of whimsy and approachability, which is perfect for seasonal or youth-centric products.

In addition to color, the choice of surface treatment is also crucial. Glossy coatings can enhance brightness and make the pattern more eye-catching under retail lighting, while matte coatings can soften reflections and highlight embossed textures. Additionally, functional surface treatments can also be considered, such as scratch-resistant transparent coatings or anti-fingerprint laminates. These protective layers can protect the integrity of the pattern on the custom can, ensuring that the packaging remains intact from production to consumer use.

Materials and surface treatments to ensure that the pattern is durable

While the aesthetics of the pattern are crucial, functional durability also ensures that the custom tinplate can maintain its visual appeal throughout distribution and use. The tinplate can body has a smooth surface that is easy to print, but coating adhesion may change if it is not properly pre-treated. Therefore, surface cleaning and phosphating steps are essential during manufacturing to remove oils and promote ink adhesion.

Additionally, treatments such as primer coatings or chemical etching can enhance ink adhesion on complex graphics, thereby reducing the risk of chipping or fading. Using corrosion-resistant paints ensures that the can and its graphics will last in high-humidity or cold-storage environments. These measures provide a seamless transition from production to consumer use, protecting your custom can graphics from environmental stresses.

Prototyping and Graphic Refinement Testing

Before you go into production, prototyping your custom tin can graphics is essential. Rapid sample production enables you to evaluate color accuracy, graphic alignment on curves, and the finished product under real-world lighting conditions. By working with these prototypes firsthand, stakeholders can identify unexpected color shifts, registration errors, or inconsistencies in the finished product that may not be visible on flat roofs. Additionally, accelerated durability testing can reveal the durability of your graphics throughout the entire supply chain. If repeated handling or stacking during transportation causes wear or abrasions on the print, you can adjust the ink formulation or add a protective clear coating. Integrate these insights back into the design process to ensure that your final custom graphics not only look amazing but also function effectively.

Achieving the perfect graphic

Optimizing the surface graphics of a custom tin can is a multifaceted task that requires the perfect blend of artistic vision and technical precision. From defining a graphic that matches your brand and selecting the right printing technology to choosing a color combination and ensuring the durability of the graphic, every decision will affect how your packaging resonates with consumers. By employing rigorous prototyping, testing and quality control measures and working with an experienced tin can supplier, you can create a package that not only stands out on the shelf but also endures during distribution and use.