Improving Round Tensile Specimen Quality for Optimal Testing

Have you ever wondered how a minor imperfection in a material sample could lead to inaccurate test results that are critical to industries such as aerospace and automobile? Tensile testing, a common procedure to assess material strength and ductility, demands exceptional accuracy. The quality of the specimen being tested is often the decisive factor in reliable and valid results. A poorly prepared round tensile specimen could introduce weaknesses or stress points that skew data, leading to incorrect conclusions about the material’s properties.

The stakes are high: accurate tensile testing is crucial for determining whether materials can withstand stress in real-world applications, from car parts to aircraft components. This makes the preparation of round tensile specimens a vital step that shouldn’t be overlooked. With advancements in precision machining and polishing technologies, improving specimen quality is easier than ever before.

Importance of Precision in Specimen Preparation

Testing for tensile strength requires precision. A small error in the preparation of a round tensile specimen can have significant consequences, leading to inaccurate data that misrepresents the material’s true properties. In industries where material strength and reliability are of utmost importance, these errors can seriously affect safety and performance. Therefore, verifying that each specimen meets exact specifications is not just a matter of quality control but a necessity for the integrity of the entire testing process.

A key factor in precision is complying with standardized guidelines, such as ASTM E8, which outlines specimen dimensions and geometry requirements. These standards guarantee that the tensile testing process is consistent and comparable across different laboratories and testing environments. If a specimen is not prepared to these standards, it could introduce variables that affect the test results, such as stress concentrators or uneven force distribution during testing.

In addition to complying with standards, modern techniques like precision machining and careful inspection are equally important. These steps help detect and eliminate potential flaws, such as surface irregularities or dimensional inconsistencies, that could compromise test accuracy. A laboratory can reduce errors by focusing on meticulous preparation and ensuring that the test data accurately reflects the material’s performance characteristics.

Techniques to Improve Specimen Quality

Achieving the quality of round tensile specimens involves several critical machining processes designed to eliminate imperfections and guarantee accurate test results. One of the most effective techniques is precision milling and turning, which is used to shape the specimen and remove surface defects that might introduce stress concentrations during testing. This process ensures the specimen’s dimensions are consistent with testing standards, reducing test outcome variability.

After the initial machining stage, surface treatment becomes essential to further improve specimen quality. Polishing, particularly when applied to round specimens, eliminates minor surface imperfections and reduces the potential for stress risers that could affect test results. A smooth, uniform surface finish is vital for preventing premature failure and making sure that the tensile test accurately reflects the material’s mechanical properties.

In addition to these processes, effective operator training and advanced inspection techniques are vital to specimen quality. Trained technicians can spot and correct potential flaws early, while inspection tools verify that each specimen meets dimensional and surface finish standards. Combining these efforts increases the consistency and reliability of specimen preparation.

The Role of Advanced Specimen Preparation Equipment

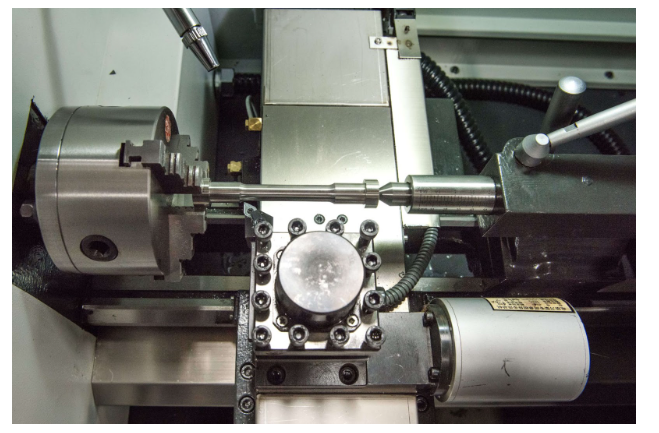

Achieving a higher quality of round tensile specimens also requires the use of advanced equipment. CNC machines have revolutionized specimen preparation by offering unmatched precision and consistency. These machines allow laboratories to produce specimens with exact dimensions, significantly reducing human error. By automating many preparation steps, CNC machines make certain that each sample adheres to international standards, such as ASTM or ISO, without the need for constant manual adjustments. A high level of precision is necessary in order to produce reliable tensile testing results, as minor deviations in specimen size or shape can lead to inaccurate results.

In addition to CNC machines, longitudinal polishers are critical for enhancing specimen surface finishes. Polishing is a key step in minimizing residual stresses and eliminating surface imperfections that could serve as failure points during testing. The longitudinal polisher makes certain that the round specimens have a uniform, smooth surface, which is crucial for accurate tensile data. The precise control offered by these machines allows operators to adjust parameters such as polishing force and speed so that each specimen is polished to the exact specifications required for high-quality testing.

Together, CNC machines and longitudinal polishers ensure that the tensile specimens produced are of the highest possible quality, and ready for testing without defects or inconsistencies. These technologies not only improve testing accuracy and reliability but also significantly enhance productivity in testing laboratories by automating the specimen preparation process.

Achieving Reliable Testing through Quality Specimen Preparation

In tensile testing, the quality of the specimen is often the deciding factor in the reliability of the results. From precise machining to careful surface treatment, every step in the preparation process contributes to minimizing potential defects that could skew test outcomes. Making sure that a smooth and consistent surface, free from imperfections, is essential for avoiding premature failure during testing, which is why attention to detail in both milling and polishing is so critical.

The use of advanced preparation techniques, alongside skilled operators, guarantees round specimens meet the highest standards. As industries increasingly depend on accurate material testing to drive safety and innovation, adopting these best practices ensures that tensile testing data is both reliable and insightful. By investing in high-quality preparation methods, laboratories, and industries can confidently assess the strength and performance of their materials, thereby meeting their application requirements.