Precast Concrete Accessories At Hulk Constructions

Concrete lifting anchors are essential to engineering and construction operations Because they offer a safe and effective way to raise bulky concrete components. During the casting process, these specialised anchors are strategically buried within concrete buildings and are carefully constructed to withstand high loads.

The installation of architectural panels, the building of bridges, and the production of precast concrete are only a few of the many uses for concrete lifting anchors due to their adaptability. It is crucial to choose the appropriate anchor type, taking into account elements like load capacity and installation technique, to guarantee both worker safety and the structural integrity of the concrete.

Hulk construction’s concrete lifting anchors are made to withstand heavy loads. They are available in several varieties to meet different lifting needs, such as pin lifting anchors, thread lifting anchors, and flat lifting anchors. They are frequently employed in projects like building bridges, installing architectural panels and producing precast concrete.

Premium anchors for your high budget projects

Our wide selection of concrete lifting anchors provides options that are customised to meet the specific needs of your project. By selecting our premium anchors, you can guarantee the dependability and safety of your lifting operations in addition to improving construction productivity. Put your faith in our experience to provide you with superior concrete lifting anchors to enhance your building projects.

A lifting sockets concrete having a thick wall and a crimped flat end with a cross hole that is intended for lifting. To enable the forces to be transmitted into the concrete, the lifting socket needs a reinforcing tail fitted to the socket.

When using lifting socket for precast concrete construction, barrel lifting sockets with a cross hole are frequently utilised to raise beams, walls and floor slabs. To transfer the load into the concrete, a reinforcing tail needs to be installed.

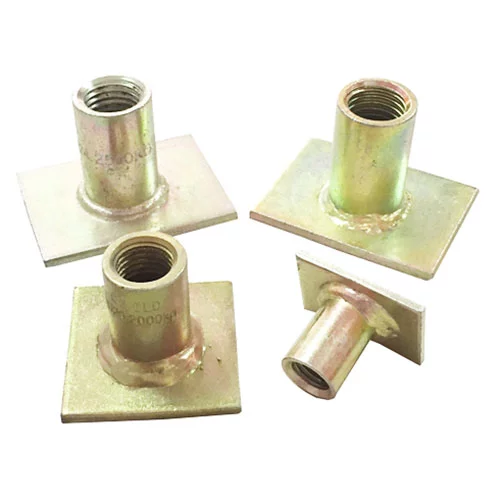

Lifting Flat Plates For concrete portions with little concrete depth, sockets are utilised. In order to ensure that the forces are transferred into the concrete, the flat steel plate permits reinforcement bars to rest on the surface. To know more, you can click here.

Precast magnets at hulk constructions

Magnetic shuttering systems, or precast concrete accessories like magnets, are incredibly useful and inventive instruments that have completely changed the building sector. These strong magnets are made especially for applications involving precast concrete, where they are essential for placing and fastening concrete components while they are being cast.

Neodymium magnets with a strong pull are housed in a sturdy steel casing in precast concrete magnets. By carefully placing these magnets within a formwork system, precast concrete components may be assembled safely and effectively. The formwork is held in place by a powerful magnetic force produced by the magnets, which enables exact alignment and placing of the concrete components.

The Spread Anchor lifting method is an excellent and economical way to move any kind of concrete component up to 22 tonnes. Ring clutches, recess formers and flat steel anchors make up the system. Because of the way the clutch and anchor are made, weights can be applied in any direction. The anchor features a hole where the clutch’s locking ring can fit. The ideal answer for almost all lifting applications is offered by this system.