The Intricacies and Advancements of Hydrocarbon Extraction Equipment

The evolving landscape of hashish and botanical extraction has visible a splendid surge in innovation, mainly within the realm of hydrocarbon extraction equipment. These specialized machines and apparatuses are meticulously designed to extract compounds, together with cannabinoids from hashish plant life or crucial oils from various botanicals, using hydrocarbon solvents like butane, propane, or hexane. This technique is pivotal in producing concentrates, oils, and extracts which are fundamental to diverse packages in pharmaceuticals, health merchandise, and past.

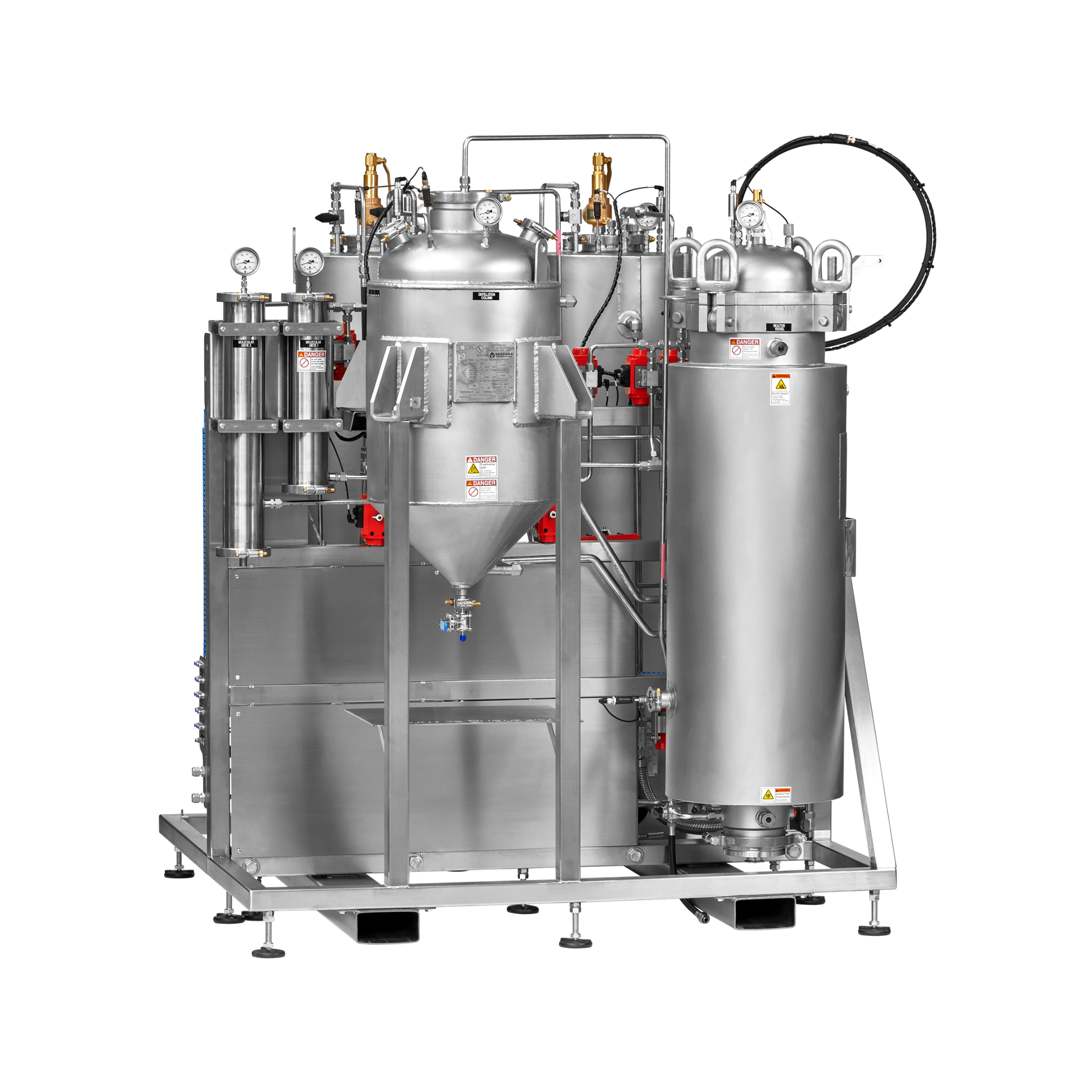

Understanding Hydrocarbon Extraction Equipment

At the heart of this extraction technique lies a set of state-of-the-art machinery engineered to facilitate the extraction technique even as making sure safety and efficiency. The equipment applied in hydrocarbon extraction contains diverse additives, each playing an essential function in the meticulous extraction method.

● Closed-loop Extraction Systems

Central to the safety and performance of hydrocarbon extraction equipment are closed-loop systems. These systems are sealed and meticulously designed to save you the break out of solvents into the environment.

Comprising extraction vessels, recovery pumps, chillers, and filtration structures, closed-loop structures now not only protect against solvent leaks but also permit the recycling of solvents. This recycling functionality now not only reduces waste but also makes the extraction procedure more sustainable and environmentally friendly.

● Extraction Vessels

The extraction vessel’s function bins in which the plant material is housed at some stage in extraction. Equipped with filtration displays or baskets, those vessels permit the solvent to bypass through whilst retaining the plant material. This vital step ensures that the preferred compounds are extracted correctly, maintaining the integrity and excellence of the very last product.

● Recovery Pumps and Chillers

Recovery pumps are hired to reclaim and recycle the hydrocarbon solvents after the extraction procedure. Simultaneously, chillers play a pivotal role in retaining the most reliable temperatures in the course of extraction, making sure that the situations are conducive to efficient extraction and solvent healing.

● Filtration Systems

Filtration structures are crucial in setting apart the extracted compounds from plant cloth and impurities. These structures paintings meticulously refine the extract, putting off undesirable particles and impurities, thereby ensuring the manufacturing of great extracts with optimum purity.

● Safety Features

Given the flammable nature of hydrocarbon solvents, safety features are paramount in these extraction setups. Pressure alleviation valves, explosion-proof electric components, and strong ventilation systems are crucial safety measures to prevent accidents and ensure the safety of workers and the surroundings.

● Post-Processing Equipment

Beyond extraction, an extra put up-processing device plays an important role in refining the extracted compounds. Techniques like winterization, distillation, and purification steps are hired to similarly system the extracts, eliminating fats, waxes, or other impurities, and refining them to achieve the favored final product with high purity and potency.

Ensuring Quality, Compliance, and Safety

These advanced extraction systems are utilized by certified manufacturers or processors running in regulated industries. Strict adherence to protection protocols and suggestions is vital to ensure the satisfaction, purity, and safety of the extracted compounds. Compliance with protection rules and complete education in coping with hydrocarbon extraction gadgets are vital because of the potential dangers associated with running with flammable solvents.

Advancements and Future Outlook

Continual advancements in extraction technology and methodologies are using the evolution of hydrocarbon extraction equipment. Researchers and producers are constantly innovating to enhance efficiency, enhance safety capabilities, and broaden extra sustainable extraction procedures. These advancements aim to in addition raise the best extract at the same time minimizing environmental impact and making sure the protection of people worried about the extraction approaches.

Precision and Consistency

Hydrocarbon extraction equipment or butane extraction machine is engineered for precision, ensuring consistent and reproducible effects. The controlled surroundings and parameters installed using those machines permit for precise manipulate of variables which includes temperature, pressure, and solvent float quotes. This precision enables manufacturers to continuously produce extracts with specific cannabinoid or compound profiles, meeting stringent satisfactory requirements and supplying purchasers with dependable merchandise.

Scalability and Production Efficiency

The scalability of hydrocarbon extraction equipment enables producers to adapt their manufacturing capacities to fulfill marketplace demands. These systems are available in diverse sizes, allowing for flexibility in manufacturing, whether it is a small-scale operation for artisanal batches or a large-scale facility catering to mass manufacturing. This scalability, coupled with the performance of closed-loop systems and solvent recycling, optimizes manufacturing processes, lowering waste, and enhancing average operational performance.

Innovation and Technology Integration

Ongoing research and development in extraction generation always pressure innovation in hydrocarbon extraction systems. Advancements include the combination of automation, facts analytics, and advanced tracking structures.

Automation streamlines methods reduces human blunders, and ensures regular output, even as data analytics offer insights into extraction performance and product fine. Additionally, superior tracking systems provide actual-time records on manner variables, permitting instant changes and optimization, in addition to improving the exceptional efficiency of extraction tactics.

Final Words

In conclusion, the hydrocarbon extraction system stands as the spine of the cannabis and botanical extraction industries. Its meticulous design, adherence to safety requirements, and chronic improvements underscore its pivotal role in extracting compounds efficaciously, sustainably, and with uncompromised best, paving the manner for the various applications of these extracted compounds in diverse industries.