The Manufacturing Process of Double-Sided PCBs: From Design to Production

Double-sided printed circuit boards (PCBs) are fundamental components in modern electronic devices, providing a compact and efficient means of connecting electronic components. The manufacturing process of double-sided PCBs involves several critical steps, from initial design to final production. This article will guide you through each stage of the manufacturing process, highlighting key considerations and technologies involved.

Design Phase

Schematic Design

The process begins with creating a schematic diagram using PCB design software such as Altium Designer, Eagle, or KiCAD. This diagram represents the electronic circuit and illustrates how each component connects to others.

Designers must consider the placement of the components, the flow of the signals, and the paths for the power and ground connections.

Layout Design

After finalizing the schematic, the next step is translating it into a physical layout. This layout determines the components’ exact positions and the routing of the traces on both sides of the PCB.

Designers must consider trace width, spacing, and via placement to ensure signal integrity and manufacturability. They also need to account for thermal management and potential interference between components.

Design Rule Check (DRC)

Once the layout is complete, a design rule check is performed to ensure the design adheres to specific manufacturing requirements, such as minimum trace width and spacing. This step helps to identify any potential issues that could arise during fabrication.

Preparation for Manufacturing

Gerber File Generation

After the design is verified, the next step is to generate Gerber files. These files contain detailed information about the PCB layers, including copper, solder masks, and silkscreen.

The Gerber files are the primary input for PCB manufacturers, detailing the specifications needed to fabricate the PCB accurately.

Bill of Materials (BOM) Creation

A comprehensive bill of materials (BOM) is prepared, listing all components required for assembling the PCB. This includes part numbers, descriptions, quantities, and specifications.

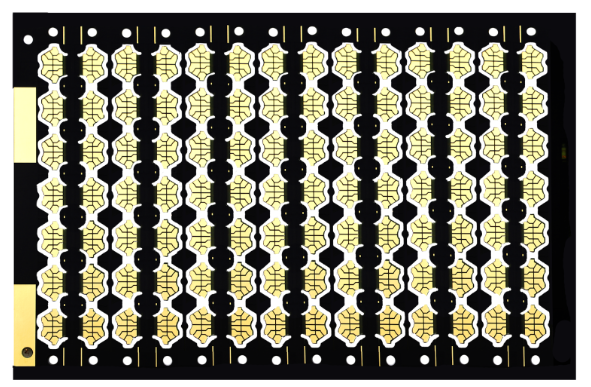

Fabrication Process

Material Selection

The primary material for double sided PCB is a laminate substrate, typically FR-4, consisting of a fibreglass cloth impregnated with epoxy resin. Other materials like polyimide or aluminium may be used for specific applications.

The copper foil was also chosen based on the required thickness and conductivity.

Layer Construction

Copper Cladding: The process begins with applying copper foil to both sides of the substrate using heat and pressure.

Drilling: Holes are drilled into the PCB for component leads and vias. Depending on the precision required, laser or mechanical drills can be used.

Plating: The drilled holes are plated with copper to create electrical connections between the two sides of the board. This involves an electroplating process that deposits copper onto the hole walls.

Photoresist Application and Exposure

A photoresist layer is applied to the copper-clad substrate. This light-sensitive material will define the copper traces.

The board is then exposed to UV light through a photomask outlining the desired circuit pattern. The exposed areas of the photoresist are then developed to reveal the copper beneath.

Etching

The exposed copper is removed using an etching solution, leaving only the desired copper traces on the PCB. This step is critical for creating the intricate pathways needed for electrical connections.

Solder Mask Application

A solder mask is applied to protect the copper traces from oxidation and to prevent solder from bridging between conductors during assembly. The solder mask is typically a green epoxy coating that covers the entire board except for the areas where components will be placed.

Silkscreen Printing

A silkscreen layer, usually white, is printed on top of the solder mask to display component labels and other relevant information. This step aids in assembly and troubleshooting.

Finalizing the PCB

Surface Finish

To improve solderability, the exposed pads are treated with a surface finish. Common finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or OSP (Organic Solderability Preserver).

Testing and Quality Control

Before the boards are sent for assembly, they undergo testing to ensure they meet the required specifications. This may include electrical testing, visual inspection, and automated optical inspection (AOI).

Functional testing may also be conducted on a sample of boards to verify performance.

Assembly Process

Component Placement

Components listed in the BOM are manually placed onto the PCB or used with automated pick-and-place machines. This process can vary depending on the complexity and volume of production.

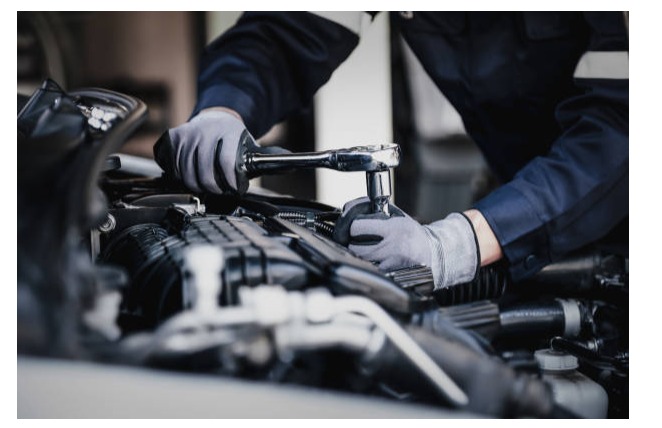

Soldering

After component placement, soldering creates electrical connections. Depending on the component type and board design, this can be done using wave soldering, reflow soldering, or hand soldering techniques.

Inspection and Testing

Post-assembly, the PCB undergoes thorough inspection and testing to ensure all components are correctly soldered, and the board functions as intended. This may include X-ray inspection for BGA (Ball Grid Array) components and functional tests.

The manufacturing process of double-sided PCBs

The manufacturing process of double-sided PCBs is a complex yet fascinating journey from design to production. Understanding each step, from the initial design phase to assembly and testing, provides valuable insights into how these essential components are created. As technology advances, the processes and materials used in PCB manufacturing will evolve, leading to even more innovative and efficient designs in the future. Double-sided PCBs will remain a crucial element in the electronics industry, enabling the development of smaller, faster, and more reliable electronic devices.