What is the difference between long tube headers 5.7 Hemi and 99-06 Silverado long tube headers

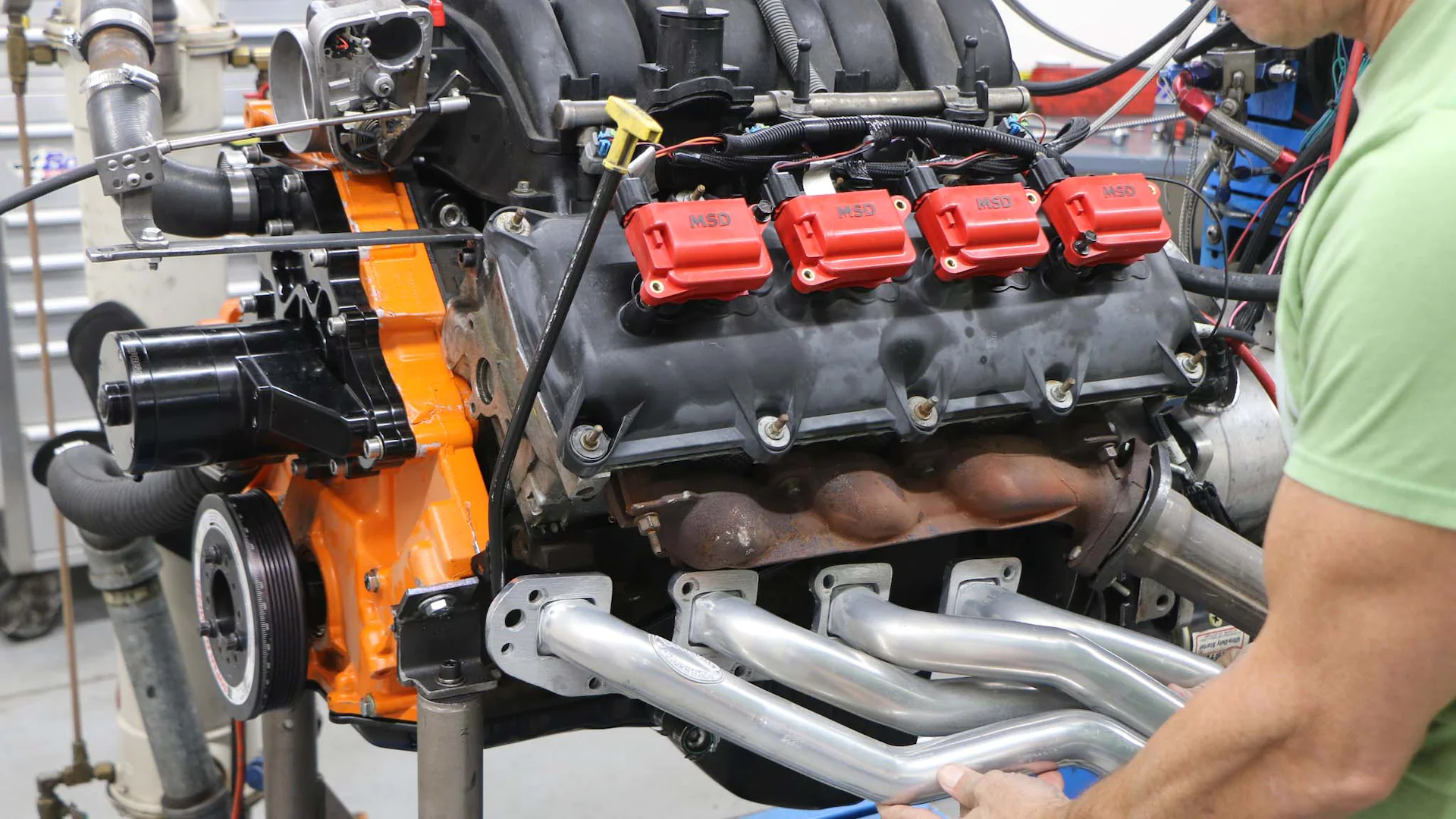

Long tube headers for a 5.7 Hemi engine and a 1999-2006 Silverado serve similar purposes but are tailored to the specific engine configurations of each vehicle. Long tube headers are aftermarket exhaust components designed to improve engine performance by enhancing exhaust gas flow. They replace the restrictive factory exhaust manifolds with longer, individual tubes for each cylinder. In the case of a 5.7 Hemi, long tube headers help optimize exhaust scavenging, reducing backpressure and increasing horsepower and torque output.

These headers provide similar benefits for 99-06 Silverado long tube headers by improving exhaust flow, enhancing engine efficiency, and boosting power. Both applications can lead to better throttle response, increased overall performance, and a more aggressive exhaust note. However, ensuring compatibility with the specific engine and vehicle is crucial to achieving the desired results effectively.

The difference between long tube headers 5.7 Hemi engine and those for a 1999-2006 Silverado (presumably with a different machine) involves considering factors related to fitment, design, and compatibility. Here’s how you can generally differentiate between the two:

Engine Compatibility:

The most crucial factor is ensuring that the long tube headers are designed to fit your specific engine. The 5.7 Hemi and the Silverado’s engines will likely have different dimensions, mounting points, and exhaust port configurations. Make sure the headers are explicitly listed as compatible with your engine.

Exhaust Port Configuration:

Different engines have different exhaust port shapes and sizes. The headers need to match these ports for efficient exhaust flow. Check if the headers are designed to match the exhaust ports of your engine.

Header Tube Length and Diameter:

Long tube headers are designed to optimize exhaust flow for increased performance. Different engines may require specific tube lengths and diameters to achieve the best results. Make sure the headers you’re considering have the appropriate tube dimensions for your engine.

Oxygen Sensor Locations:

Modern vehicles have oxygen sensors monitoring exhaust gas emissions and fuel efficiency. Ensure that the headers have provisions for mounting the oxygen sensors in the correct locations for your vehicle.

Material and Construction:

The quality of materials used and the construction of the headers can impact durability and performance. Look for headers made from high-quality materials such as stainless steel, and consider factors like weld quality and overall build.

Installation Process:

Consider whether the headers are designed for a direct bolt-on installation or if modifications are required. Some headers may require additional components or modifications to fit properly.

Brand and Reputation:

Reputable brands that specialize in exhaust systems and headers are more likely to provide accurate fitment and compatibility information. Research and read reviews from other users who have installed similar headers on the same type of vehicle.

Performance Claims:

Pay attention to any performance claims associated with the headers. Reputable manufacturers often provide dyno-tested data or performance gains associated with their headers.

Legal Compliance:

Ensure that any modifications you make to your vehicle, including installing headers, comply with local emissions regulations and laws.