Why GTC Pumps Mechanical Seal Pump Is Trusted in Oil & Gas Applications

Oil and gas are among the most challenging and adverse sectors in the world. It works with high temperatures, severe pressures, and severe chemicals, which can easily destroy the equipment unless it is constructed sturdy enough. Pumps form the central part of most oil and gas processes as they handle fluids that vary in properties between water and crude oil to corrosive chemicals and hot gases. Pump failure in this industry can lead to loss of time, safety, and even environmental damage. That is why selecting a pump is very significant. GTC Pumps has developed a good reputation for creating pumps that will fulfil the precise requirements of high-risk industries. The mechanical seal pump is one of the products offered by the company in its broad product line; it is a reliable solution for oil and gas applications. It is durable, safe, and performs well, thus qualifying it as a good companion in such a demanding profession.

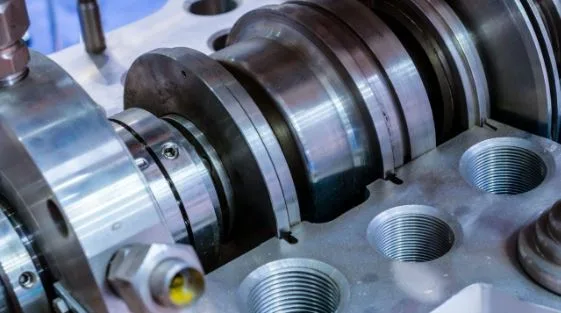

Built for Harsh Environments

Among the largest factors that have made GTC mechanical seal pumps a trusted choice in oil and gas is that they can withstand difficult working environments. The oil and gas industry is frequent, as it is always accompanied by extreme heat, high pressure and abrasive or corrosive fluids. This environment cannot sustain many pumps, and GTC pumps are specifically created to work in this environment. These pumps are made with materials of fine quality that do not wear out easily and are also resistant to corrosion, meaning that they can serve a longer life even when subjected to challenging fluids. The concrete construction will minimize the risks of cracks, leakages or unexpected failures, as far as tough operations are known to be risky. This renders the mechanical seal pump a safe and more affordable alternative to companies that cannot afford to put their feet up.

Reliability in Continuous Operations

Pumps in the oil and gas industry are continuously used and may operate for long hours or even days without interruption. Failure in any of them can lead to losses and time wastage. The GTC mechanical seal pump is designed to consistently and reliably function without interruption. The mechanical seal helps the pump maintain a constant rate and prevents leaks. It is particularly necessary in the process of handling hazardous fluids that should not leak into the environment. The pump has been designed in such a way that it minimizes wear and friction, hence can operate continuously over a long period and is therefore a reliable source when it comes to handling a critical operation.

Safety as a Top Priority

One of the greatest concerns in the oil and gas industry is safety. Accidents, fire, or damage may result due to pump leaks or failure. The GTC mechanical pump seal is safe. The seal system provides a system of containing fluids inside the pump, and this is applicable in deterring the potential risk of lethal leaks. This safeguards the workers, equipment and the surrounding environment. Moreover, the robust construction of the pump implies that it can tolerate the instant pressure or temperature changes without collapsing. GTC pumps ensure that companies have safer working conditions since they reduce the risks.

Long Service Life and Lower Maintenance

Oil and gas facilities are always faced with the problem of maintenance. Machinery that fails to work regularly has the potential to halt production and introduce excessive repair expenses. GTC mechanical seal pumps are built to reduce this issue. Their robust structure, coupled with a trusted sealing technology, implies that they do not have to be serviced as often as standard pumps. They are able to work with the corrosive and abrasive fluids without deteriorating rapidly. This means that companies will save on time and money spent on unnecessary repairs and replacements. The longer service life also implies that there is less disruption of the operational day.

Energy Efficiency

Oil and gas facilities are always faced with the problem of maintenance. Machinery that fails to work regularly has the potential to halt production and introduce excessive repair expenses. GTC mechanical seal pumps are built to reduce this issue. Their robust structure, coupled with trusted sealing technology, implies that they do not require as frequent servicing as standard pumps. They can work with the corrosive and abrasive fluids without deteriorating rapidly. This means that companies will save on time and money spent on unnecessary repairs and replacements. The longer service life also implies less disruption to the operational day.

Proven Track Record

GTC Pumps has gained extensive experience over the years in providing reliable pumping solutions to industries that require them. They have a record of high quality and performance in the oil and gas field. GTC mechanical seal pumps are already being deployed in demanding facilities worldwide, where they have proven to be reliable in practice. This historical track record assures oil and gas companies that they are investing in tested and proven equipment in the field. One of the reasons why GTC continues to be a preferred choice among most organizations in this sector is its track record.

Supporting Safe and Sustainable Operations

The oil and gas industry is facing increased pressure to act safely and responsibly. Leaking, spills, and other environmental damage-reducing equipment are increasingly important. GTC mechanical seal pumps contribute to this objective, as they offer safe containment of dangerous fluids and minimize the risk of accidents. These pumps help companies achieve production and environmental standards by incorporating safety, durability, and efficiency. It not only benefits business, but it is also necessary to ensure the safety of workers and communities around oil and gas activities.

Conclusion

Pumps are not just machines that transmit fluids in the world of oil and gas. They constitute critical components of an operation that need to withstand harsh environmental factors, safeguard employees and secure safe and stable production. GTC mechanical seal pumps are unique in that they are designed to work in such tough conditions. These pumps have gained the confidence of companies in one of the most demanding industries due to their robust design, dependable sealing, extended service life, and established safety provisions. With such a blend of reliability and efficiency, GTC Pumps has invented a mechanical seal pump that remains significant in the oil and gas operations around the world.