Facing the Furnace: How High Heat Casters Outshine the Rest

In high-temperature industrial settings, specialized equipment is not a luxury; it’s a necessity. High heat casters are a prime example of this specialized gear, engineered to withstand extreme conditions where ordinary casters falter.

Their role in facilitating smooth operations under challenging thermal scenarios can’t be overstated. As you delve into this article, you’ll discover what makes these casters indispensable and how features like casters heavy duty locking and casters wheels with brakes contribute to their superiority.

The Basics: What Makes a Caster “High Heat”

Through meticulous engineering, high heat casters cater specifically to environments with demanding temperature conditions. The foundational element of their resilience lies in the choice of materials.

Typically, metals such as forged steel or cast iron are preferred, enduring temperatures ranging from -40° to a scorching 800° F. However, not all high heat casters are metallic. Materials like High Temp Phenolic or even High Temp Nylon can resist temperatures intermittently up to 500° F and 450° F, respectively.

While lighter-duty high-temp casters find their niche in bakeries, the heavy duty casters are indispensable in more intense scenarios, such as sterilizing medical equipment or foundry applications.

Ultimately, selecting the right high heat caster, whether metallic or otherwise, becomes essential in maximizing performance and ensuring longevity in specific industrial environments.

Delving into Design Considerations: The Engineering behind High Heat Casters

● The Pivotal Role of High-Temperature Grease

The first line of defense in high heat casters is specialized high-temperature grease. Unlike its low-temperature counterpart, which fails at around 150 degrees Fahrenheit, this grease maintains its lubricative properties even when temperatures soar, preventing the catastrophic failure of both wheels and swivel sections.

● Bearings and Their Critical Clearances

In high-temperature applications, caster wheel bearings and their clearance isn’t just a technical specification, it’s an operational necessity. Materials expand when heated, and proper clearances are essential to accommodate this.

Options like precision ball bearings and tapered roller bearings, designed with looser clearances, excel in these conditions.

● Swivel Section Design

Standard swivel designs, especially those that are maintenance-free, aren’t recommended for high-heat environments. Kingpinless designs, equipped with internal clearances allowing material expansion, are far more suitable.

Similarly, traditional kingpin models may suffice, provided they employ tapered bearings with correct clearances for thermal expansion.

With these design intricacies, high heat casters ensure that operations remain uninterrupted and efficient, even when faced with scorching challenges.

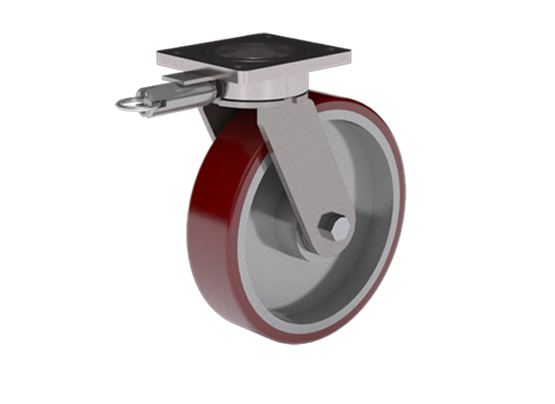

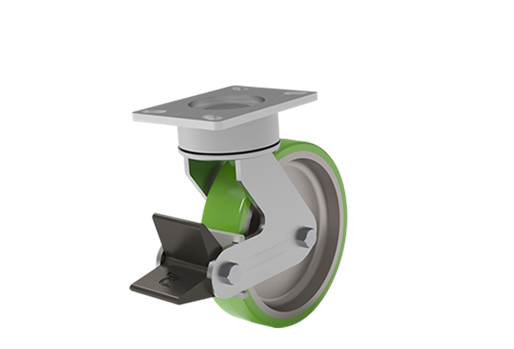

Ensuring Safety and Precision: Casters Heavy Duty Locking System

Central swivel lock systems in high heat casters add an extra layer of safety and precision. You can engage locks on multiple wheels with a single mechanism, often a foot pedal or tow bar. This eliminates the need to search for individual brake pedals, ensuring swift and effective locking.

Various heavy duty swivel locking casters are available, each serving a specific purpose and offering unique benefits.

● Field-Installed Demountable Swivel Locks

Options like the demountable swivel lock provide flexibility, allowing for field installation up to a certain caster series. These are useful for varying operational needs and are available up to the 71 Series of casters.

● Factory-Installed Swivel Locks

For those seeking pre-configured solutions, factory-installed swivel locks offer notches at 90-degree intervals. This feature is ideal for guiding straight-line movement and has options for 1, 3, or 8 locking positions.

● Foot-Operated Swivel Locks

With ergonomics in mind, foot-operated swivel locks contain pedals to engage or disengage the lock quickly. These locking mechanisms are similar to standard swivel locks, facilitating a seamless transition for operators.

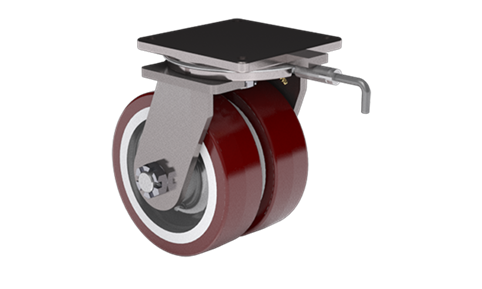

● Heavy Duty Variants

Special heavy-duty demountable swivel locks cater to the 80s and 90s series, featuring a longer, more accessible handle. These are machined from steel, enhancing their robustness and reliability.

● Passive and Vertical Mounted Swivel Locks

The passive swivel lock offers full-unit mobility, disengaging under side thrust for maximum maneuverability. Vertical mounted variants, on the other hand, are mainly used in heavy-duty applications, offering additional security due to their under-the-yoke placement.

These diverse locking options affirm that safety and precision can co-exist in high heat casters, assuring operational efficiency even in extreme conditions.

High Heat Caster Wheels with Brakes: A Safety Game Changer

Braking systems are a pivotal backup, augmenting operator control and mitigating workplace hazards. In high heat applications, brakes slow down carts and prevent accidental movements that could jeopardize product integrity and worker safety.

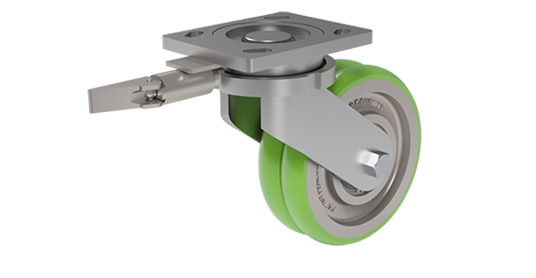

● Diversity of Brake Types

Several braking systems exist to accommodate various operational requirements. Single-side brakes prove ergonomic and efficient for medium-duty applications. Meanwhile, dual side brakes are budget-friendly options that manually lock both sides of a caster for dependable holding.

● Brakes for Heavy-Duty Applications

Face Contact and Poly Lock brakes offer a heightened holding force for heavy loads. The former employs a threaded rod mechanism for robust engagement, while the latter uses a polyurethane roller against a steel brake shoe to minimize skid risks.

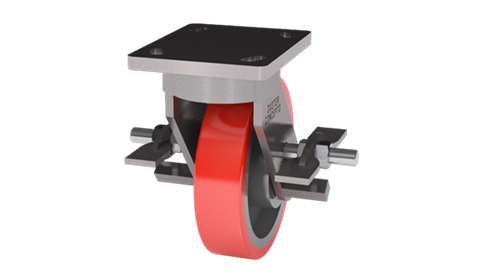

● Advanced Braking Solutions

Pneumatic Poly Cam brakes allow pressure customization against the wheel tread, which is ideal for handling extreme loads. Wrap-Around brakes alleviate alignment hassles, granting brake access irrespective of caster orientation. This significantly reduces time spent on adjustments and enhances safety.

Why High Heat Casters are the Future of Industrial Mobility?

In the rapidly evolving world of industry, high heat casters are emerging as front-runners. Their long-term economic benefits are clear: investing in these robust casters reduces equipment maintenance and replacements, offering tangible savings.

Their versatility shines across varied sectors—from baking to metallurgy, and their resilience makes them a sought-after choice. Furthermore, with continuous advancements, these casters are not stagnant.

Evolving designs, especially with the integration of custom engineered wheels, ensure they remain at the cutting edge, always meeting the ever-growing demands of modern industries.

Uplifting High Heat Caster Performance with Custom Engineered Wheels

High heat casters already dominate in resilience, but custom engineered wheels push their performance to the next level. With these bespoke solutions, efficiency and longevity go hand-in-hand.

Whether you’re retrofitting older systems or facing unique industrial challenges, custom wheels are the key to elevating your caster game.

Caster Concepts service offerings extend from simple modifications to ground-up designs, all accomplished without unduly stretching lead times or budgets.

Tailored to diverse sectors such as aerospace and manufacturing, these wheels can address specific issues like noise reduction, shock absorption, and unique material handling demands.

When it comes to meeting your precise needs, custom engineered wheels on high heat casters offer an unparalleled synergy of durability and performance.

Conclusion

The pivotal role of high heat casters in high-temperature industrial settings is indisputable. Through meticulous engineering, these casters offer a blend of durability, efficiency, and safety that traditional options can’t match. With the added benefit of custom engineered wheels, their suitability for various industries becomes even more compelling.