Aluminum Die Casting Companies in China

In the dynamic landscape of manufacturing, China stands tall as a hub for innovation and efficiency. Among its myriad industries, the aluminum die casting sector has witnessed remarkable growth. This article explores the nuances of aluminum die casting companies in China, shedding light on the intricacies of the process and the key players shaping the industry.

Key Features of Aluminum Die Casting

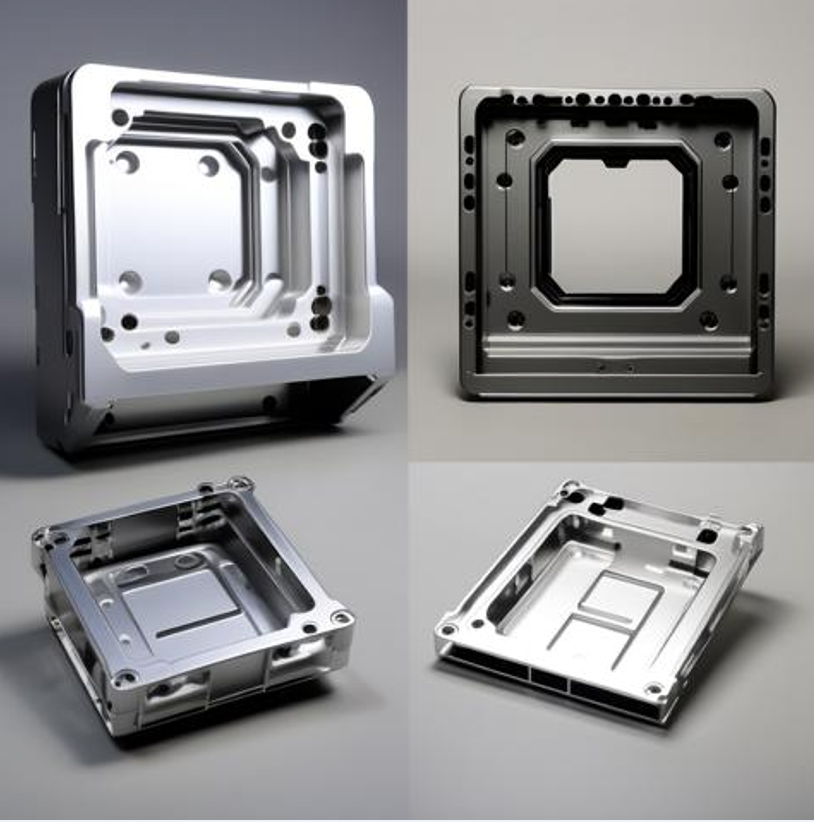

Die casting is a precise manufacturing process that involves injecting molten aluminum into a mold to produce intricate components with high dimensional accuracy. The advantages of utilizing aluminum in this process are manifold, including its lightweight nature, corrosion resistance, and excellent thermal conductivity. Common products manufactured through aluminum die casting encompass automotive parts, electronic components, and household appliances.

Overview of Aluminum Die Casting Companies in China

China’s prowess in manufacturing extends to various industries, and the aluminum die casting sector is no exception. This overview delves into the key aspects that define the landscape of aluminum die casting companies in China, highlighting the industry’s growth, market trends, and factors influencing its trajectory.

- Growth and Development of the Industry

The aluminum die casting industry in China has experienced remarkable growth over the years. Fueled by the country’s robust manufacturing ecosystem, these companies have evolved into key players on the global stage. The growth is attributed to several factors, including technological advancements, increased demand for lightweight components, and a proactive approach to adopting innovative manufacturing processes.

- Market Trends and Demand for Aluminum Die Casting Services

A notable trend in the industry is the increasing demand for aluminum die casting services. This surge is propelled by various sectors, including automotive, electronics, aerospace, and consumer goods. The automotive industry, in particular, has been a significant driver, with the need for lightweight and durable components to enhance fuel efficiency and overall performance. The electronics sector also contributes to the demand, seeking precision-engineered components for modern devices.

- Notable Factors Influencing the Industry in China

Several factors influence the aluminum die casting industry in China, shaping its dynamics and future outlook:

Technological Advancements: Chinese companies are investing heavily in cutting-edge technologies, such as advanced casting techniques, automation, and digital manufacturing. These innovations enhance efficiency, reduce costs, and improve the overall quality of die-cast components.

Regulatory Compliance and Quality Standards: Adherence to international quality standards and compliance with regulatory requirements are paramount. Companies in China are increasingly focusing on obtaining certifications to ensure their products meet the highest industry standards.

Global Supply Chain Integration: The industry is witnessing a trend towards increased integration into the global supply chain. Chinese aluminum die casting companies are establishing partnerships and collaborations with international clients and suppliers, fostering a more interconnected and collaborative manufacturing ecosystem.

- Challenges and Opportunities

While the industry flourishes, it is not without challenges. Rising material costs, global economic uncertainties, and environmental concerns pose challenges that companies must navigate. However, these challenges also present opportunities for innovation and differentiation. Companies that can address sustainability concerns, optimize production processes, and offer tailored solutions stand to capitalize on emerging opportunities.

- Future Outlook

The future of aluminum die casting China companies appears promising. As the industry continues to evolve, key trends are expected to shape its trajectory:

Smart Manufacturing: The integration of smart manufacturing practices, including the Internet of Things (IoT) and data analytics, is expected to enhance efficiency and provide real-time insights into the production process.

Sustainability Initiatives: With a growing emphasis on sustainability, companies are likely to invest in eco-friendly practices, recycling initiatives, and energy-efficient processes to align with global environmental goals.

Diversification of Applications: The versatility of aluminum die casting ensures its applicability across various industries. Companies in China are likely to explore new applications and markets, expanding their reach beyond traditional sectors.

The aluminum die casting industry in China continues to be a driving force in the global manufacturing landscape. With a commitment to innovation, adherence to quality standards, and a proactive approach to emerging trends, these companies are poised for sustained growth and influence in the years to come.

Selection Criteria for Aluminum Die Casting Companies

Selecting the right aluminum die casting partner is critical for ensuring the success of a project. Key criteria include adherence to quality standards and certifications, production capabilities, and industry reputation. Prospective clients should meticulously evaluate a company’s track record and customer reviews to gauge its reliability.

Factors to Consider When Choosing an Aluminum Die Casting Partner

Choosing the right aluminum die casting partner is a critical decision that can significantly impact the success of a project. Here are key factors to consider when evaluating potential partners in this specialized manufacturing process:

- Quality Standards and Certifications

Ensure that the prospective aluminum die casting partner adheres to stringent quality standards and holds relevant certifications. Quality certifications such as ISO 9001, ISO/TS 16949 (for automotive applications), and other industry-specific standards are indicative of a commitment to excellence. These certifications demonstrate a partner’s dedication to maintaining consistent quality throughout the production process.

- Production Capabilities and Capacity

Evaluate the production capabilities and capacity of the aluminum die casting partner. Consider factors such as the size and complexity of components they can produce, the types of materials they work with, and their overall production capacity. A partner with advanced machinery, state-of-the-art facilities, and a demonstrated ability to handle projects of varying scales is more likely to meet your manufacturing needs effectively.

- Industry Reputation and Customer Reviews

Research the reputation of the potential partner within the industry. Look for reviews, testimonials, and case studies from previous clients. A company with a positive track record, satisfied customers, and successful project deliveries is more likely to be a reliable and trustworthy partner. Assess their reputation for delivering on time, meeting specifications, and providing excellent customer service.

- Specialized Services or Products

Consider whether the aluminum die casting partner offers specialized services or products that align with your specific requirements. Some companies may have expertise in particular industries or excel in producing complex components. A partner with experience in your industry or with similar project requirements may bring valuable insights and efficiency to the collaboration.

- Innovation and Technology Adoption

Assess the partner’s commitment to innovation and the adoption of cutting-edge technologies. The use of advanced casting techniques, automation, and digital manufacturing processes can enhance efficiency, reduce costs, and improve the overall quality of die-cast components. A forward-thinking partner is more likely to provide innovative solutions and stay ahead of industry trends.

- Location and Logistics

Consider the geographical location of the aluminum die casting partner in relation to your business. Proximity can impact shipping costs, lead times, and overall logistics. Additionally, assess the partner’s logistical capabilities, including their ability to handle international shipments if applicable. Efficient logistics contribute to smoother collaboration and timely project completion.

- Cost Considerations

While cost should not be the sole determining factor, it is undoubtedly an essential consideration. Obtain detailed quotes from potential partners, including a breakdown of costs for materials, labor, and any additional services. Compare these quotes against the overall value offered, considering factors such as quality, expertise, and the partner’s ability to meet project timelines.

- Communication and Collaboration Capabilities

Effective communication and collaboration are vital for successful partnerships. Assess the partner’s communication processes, responsiveness, and willingness to collaborate closely with your team. Clear and transparent communication fosters a better understanding of project requirements, reduces the likelihood of errors, and enhances the overall project experience.

In conclusion, the selection of an aluminum die casting partner should involve a comprehensive evaluation of their capabilities, reputation, and compatibility with your project requirements. By considering these factors, you can make an informed decision that aligns with your manufacturing goals and ensures a successful and mutually beneficial collaboration.

Future Trends in the Aluminum Die Casting Industry in China

Looking ahead, the aluminum die casting industry in China is poised for continuous evolution. Technological advancements, sustainability initiatives, and the potential challenges and opportunities on the horizon will shape the industry’s trajectory. Staying abreast of these trends is crucial for businesses seeking long-term success.

Conclusion

In conclusion, the world of aluminum die casting in China is a realm of innovation and precision. As businesses contemplate their manufacturing needs, the robust capabilities of Chinese companies in this sector beckon. The future looks promising, with advancements in technology and a commitment to sustainability paving the way for a new era in aluminum die casting excellence.

Welcome to GC Precision Mould: Your Leading Aluminum Die Casting and Plastic Mold Manufacturer in China

Explore excellence in manufacturing with GC Precision Mould, your premier destination for top-quality aluminum die casting, zinc die casting and precision plastic molds. As a specialized China mold manufacturer and die casting maker, we take pride in our expertise in producing high-quality components from materials such as aluminum, zinc, and magnesium.

Unparalleled Expertise in Aluminum Die Casting

At GC Precision Die Casting China manufacturer, our commitment revolves around providing our clients with the finest aluminum die casting products and services. Our team of skilled engineers and technicians utilizes state-of-the-art technology and advanced techniques to ensure that every aluminum die-cast part we produce adheres to the highest standards of quality and accuracy.

Versatility Across Industries

Our range of products finds extensive applications across diverse industries, including automotive, consumer electronics, medical, and industrial equipment. Working closely with our clients, we tailor our solutions to meet specific needs and develop custom solutions that align with unique requirements. From concept to completion, we prioritize precision and quality in every aluminum die casting project.

Precision Plastic Molds for Your Unique Requirements

In addition to aluminum die casting, we specialize in the production of high-quality plastic molds. Leveraging our team’s expertise and the latest technology, we ensure that each plastic mold meets stringent quality standards. These molds are integral to various applications, contributing to the production of components across industries.

Comprehensive Solutions for Your Manufacturing Needs

Whether you require a single plastic mold or a complete aluminum die casting production line, GC Precision Mould has the expertise and resources to deliver exceptional results. Our commitment to precision extends to every project, ensuring that your manufacturing goals are not only met but surpassed. We invite you to explore our comprehensive range of services tailored to the aluminum die casting and plastic mold requirements.

Industries We Serve:

Automotive: Elevate your automotive components with precision aluminum die casting.

Consumer Electronics: From intricate parts to casings, our products play a vital role in the consumer electronics industry.

Medical: Contribute to the medical field with precision components produced through aluminum die casting.

Industrial Equipment: Our versatile solutions cater to the diverse needs of industrial equipment manufacturing.

Your Manufacturing Partner of Choice

At GC Precision Mould, we invite you to discover more about our services and how we can assist you in achieving your manufacturing goals. Whether it’s aluminum die casting or precision plastic molds, we have the expertise to meet your unique requirements. Contact us today to learn more and get the best solutions for your aluminum die casting and plastic mold projects. Your success is our priority, and we look forward to being your trusted manufacturing partner in China.